A Flexible Strategy for a Flexible Shop

“Dynamic” is a fitting term for both this mold manufacturer and a CAM software capability that helps adapt to widely varying cutting conditions.

According to the shop, smoother surface finishes and tighter tolerances provided by Dynamic Motion technology reduce the need for secondary operations to eliminate flashing.

As a prototype mold manufacturer, Dynamic Plastics “sees a little bit of everything,” says Tom Prebelich, tooling supervisor. The same might be said of the company’s cutting tools, and, for that matter, the cutting tools used by any manufacturer tasked with machining a range of parts with widely varying geometries.

Overall, a flexible structure helps this shop adapt as-needed. However, it was only recently that the company could claim the same luxury for its cutting tools. Historically, employees often had to choose between spending inordinate amounts of time adjusting parameters to accommodate changing material conditions, or just dial back and run slower.

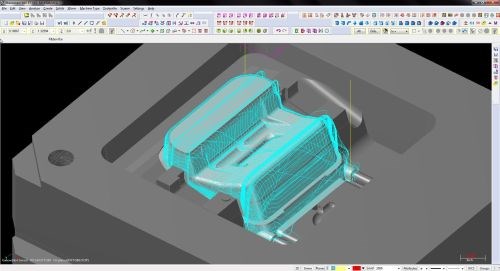

That all changed with the adoption of Dynamic Motion technology from Mastercam. By adjusting parameters automatically with no input from the programmer, the capability has significantly reduced programming and machining time alike. This results in an even more dynamic process—one that proves that both the shop and the software capability are aptly named. Read the full story.

.jpg;maxWidth=300;quality=90)