MMT Blog

Do a Technology Risk Assessment to Protect Your Shop

The road to protecting your shop’s information starts with a technology risk assessment that identifies areas to protect and areas to consider public knowledge.

Read MoreAmerimold 2019: Attendees Will Benefit from Educational In-Booth Demos

Amerimold presents in-booth demonstrations of 3D printing, machining, hot runners, mold maintenance, molding, and more.

Read MoreAmerimold 2019 Update: What You Should Know about Public Policy

This panel will review trade and tariff updates and their impact on mold manufacturing, plastics and die casting markets; and exchange rates and how they affect export/import competitiveness.

Read MoreConsiderations for AM Powder for Tooling

The start of any good product is the raw material, and that includes additive manufacturing powder for tooling.

Read MoreEmployment Opportunity: Tool Shop Supervisor

North American Lighting (NAL), located outside of Evansville, IN, seeks an individual to be responsible for second shift mold making production, at the Indiana Tool Plant (ITP), in Elberfeld, IN.

Read MoreSystems and Structure Empowers Employees and Reduces Challenges and Leadtimes

A team will achieve company objectives and improve customer service with a common understanding of processes.

Read MoreEncoders, Flow Regulators and Stabilizing Cylinders Make Mold Spotting More Efficient, Precise and Cost-Effective

For complex molds, Cavalier Tool & Manufacturing counts its advanced spotting press among its most valued pieces of shop-floor equipment.

Read MoreAmerimold 2019: Strategies to Help Strike Up A Conversation

Sometimes, changing your approach to meeting current and potential customers at a trade show can help open valuable conversations that help make that sale.

Read MoreBreaking Down the Brand Barrier

A podcast about a podcast? Yep. MoldMaking Technology and The Manufacturing Alliance are guests on the Kula Partners marketing podcast sharing how they use stories and personal connections to break down the brand barrier.

ListenChallenges, Opportunities and Solutions for Emerging Moldmaking Leaders

Young professionals at the American Mold Builders Association (AMBA) 2019 Conference sat down to discuss the challenges facing them in the industry, as well as identify opportunities and solutions to meet those challenges head on.

Read MoreAmerimold 2019 Update: What You Should Know about a Mold Builder’s Role in IMD Work

This presentation will review the various challenges a tool shop must consider before and during IMD.

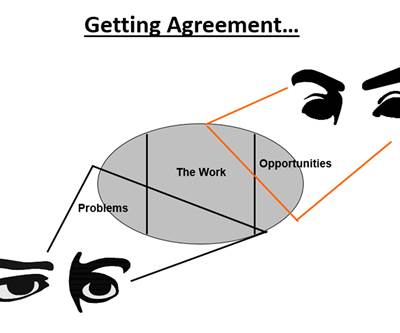

Read MoreLeaders Helping Leaders, Part 2

More highlights from a Peer-to-Peer Exchange session held during the American Mold Builders Association’s annual conference.

Read More