Automation and Apprenticeships?

We talk a lot about automation. Automation involving pallet changers, tool changers, work cells, and robots. But what does automation have to do with apprenticeships? As it turns out, plenty.

We talk a lot about automation. Automation involving pallet changers, tool changers, work cells, and robots. But what does automation have to do with apprenticeships? As it turns out, plenty.

I’ve spoken to enough of you to understand the struggles you experience with not only finding skilled workers but efficiently onboarding and training each one (like still using handwritten hour logs). And if you have several at one time, things can get more cumbersome. So, when a press release for a solution developed by two college students who claim it dramatically eases the onboarding process and management of apprentices, I had to follow up.

And think beyond a system that is limited to cataloging apprentice participation and partner data that is only used in some states and solely registering apprentices with the Department of Labor. Think functionality that does more.

William Lippolis and Shawn Kotch founded ApprentiScope while attending the University of Vermont after they discovered how “underserved traditional vocational apprenticeship workforces were, despite how critical these programs are to companies and individuals wanting to learn skills and earn wages apart from traditional higher education institutions”.

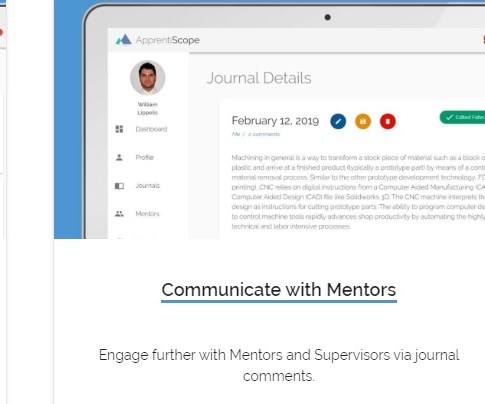

ApprentiScope offers a solution designed to streamline the apprenticeship management process, which includes reducing onboarding time from an average of two weeks to merely minutes, according to Lippolis. By automating and centralizing required state forms, spreadsheets, timesheets, journal entries, and pre-populating certain data throughout the paperwork, formal apprenticeship programs are easier to access and manage for both apprentice and employer.

ApprentiScope generates the appropriate forms for registering apprentices with the DOL and non-federal states, but also manages data for apprentices throughout the term of their apprenticeships, such as hour logs, journal entries, competency evaluations, and Related Technical Instruction completion.

It also provides companies with a platform for Real-time Mentoring offering features like video chat and screen sharing to augment and facilitate mentor-apprentice interactions. “The result is a net value add for companies when switching to ApprentiScope from other similar platforms and their current management practices,” Lippolis says.

Lippolis assures me that this solution works regardless of the size of the company. However, the benefit to applying Apprentiscope scales with how many people it applies to. For example, if you’re saving two hours per week per apprentice, then if you have more apprentices, you're saving more time.

Just throwing it out there as it might be worth a look.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.