MMT Blog

How to Avoid Premature Mold Failure

A look at the most common types of mold damage, practical examples, causes, and recommended solutions.

Read MoreNoteworthy News: Helping Hands

As we hear so often in moldmaking, building relationships is one of the keys to a business’s success. So, here’s a look at some recent new releases detailing partnerships within the industry!

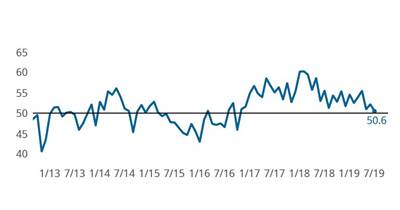

Read MoreMoldmaking Index Expands on Supplier Deliveries

The Moldmaking Index reported a record-breaking 33-month continuously expanding activity driven by supplier deliveries.

Read MoreDie Sep Demo at Amerimold 2019

Die Sep showcases their mold separator and tipper, giving Amerimold attendees the chance to see a 90 second mold removal process.

WatchMore from K 2019

K 2019 show organizers share insight on automation trends in plastics, which will be evident on the show floor October 16-23 in Germany.

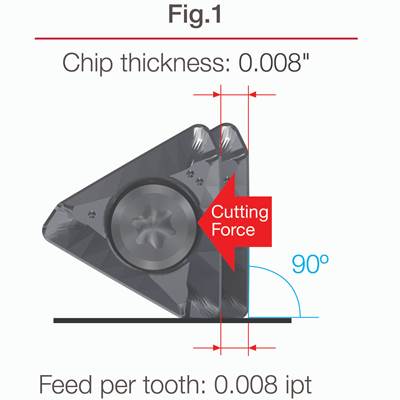

Read MoreHow to Achieve Accelerated Milling

High-feed milling reduces cycle time and extends cutting tool life.

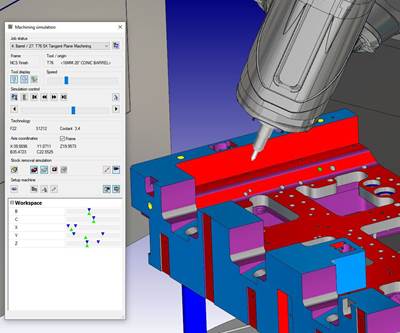

Read MoreCAM Software Speeds Programming and Optimizes Production

Precision Mold and Machining Services gains more control, accuracy and capacity, and better surface finish, with high-performance CAM software.

WatchSeasoned Moldmakers and Advanced Technologies Give Del-Tool A Cutting-Edge Advantage

For Del-Tool Co. Inc., a seasoned crew using automation, five-axis CNC and shop management software is the edge needed for continued success.

Read MoreShorten Cycle Times with Automatic Slug Removal

Automatic EDM slug management systems yield unmanned, lights-out operations, shorten cycle times and allow roughing and finishing operations with zero operator intervention.

Read MoreNoteworthy News: Bigger & Better!

Last week, we focused on some of the new faces and personnel updates in moldmaking, so for this week, take a look at recent news releases of new places. Between grand openings and expanding shops, it looks like some moldmaking companies are just getting bigger and better!

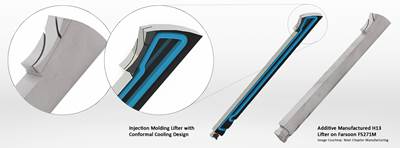

Read MoreH13 Laser Sintering Process for Robust Tooling

Partnership is the key to developing advanced process parameters for producing robust H13 tooling using laser sintering process.

Read MoreInjection Molding Simulation Prediction vs. Actual

Simulations have come a long way in the last three decades, but if we seek to prevent dimensional variation, we must understand what provides the highest level of accuracy so we can make good injection mold engineering decisions.

Read More

.JPG;maxWidth=400;quality=70)