How to Achieve Accelerated Milling

High-feed milling reduces cycle time and extends cutting tool life.

Cycle time plays a major role in productivity and often determines the profitability of any given job in today’s hypercompetitive machining market. Simply increasing the speed or revolutions per minute (RPM) may appear to decrease cycle time. However, the time it takes to change inserts hampers any reduction in cycle time, as the increase in speed or RPM shortens tool life, increasing cutting tool cost.

High-feed milling (HFM) is a solution to this problem. The tool works at elevated feed rates with modest speed or RPM, which reduces cycle time while extending tool life. These flexible and versatile tools can yield dramatically reduced cycle time and cost, long tool life and high-quality finished parts.

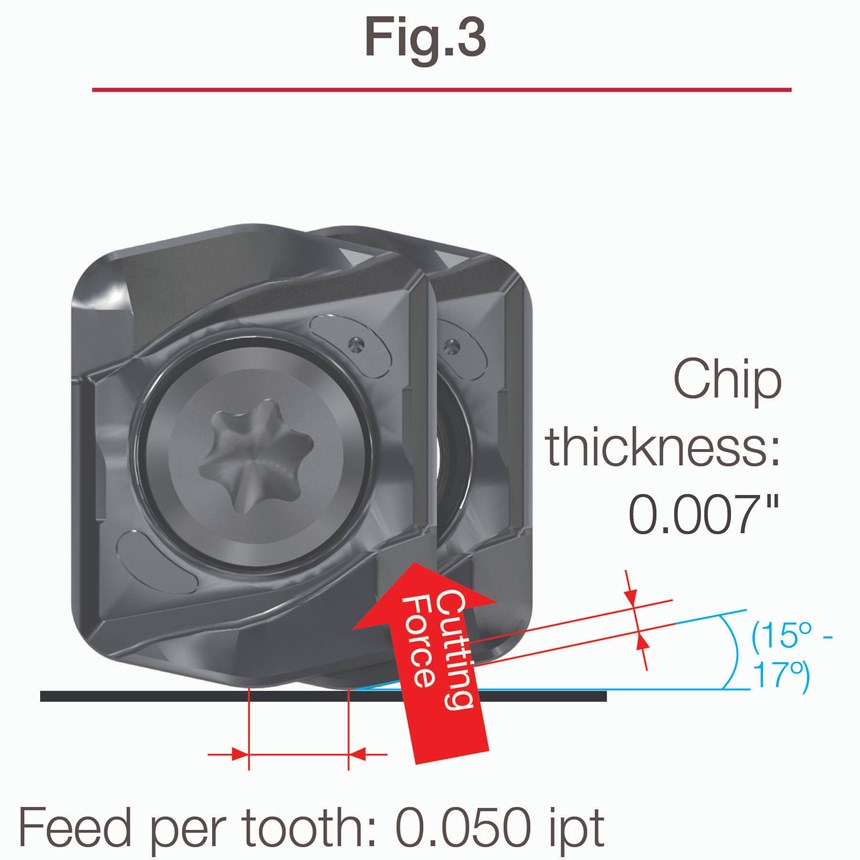

First used in mold and die machining, HFM pairs shallow depth of cut with a high feed rate up to 0.08-inch per tooth to maximize the amount of metal being removed from a part, resulting in machining more parts faster.

How It Works

First used in mold and die machining, HFM pairs shallow depth of cut with a high feed rate up to 0.08-inch per tooth to maximize the amount of metal being removed from a part, resulting in machining more parts faster.

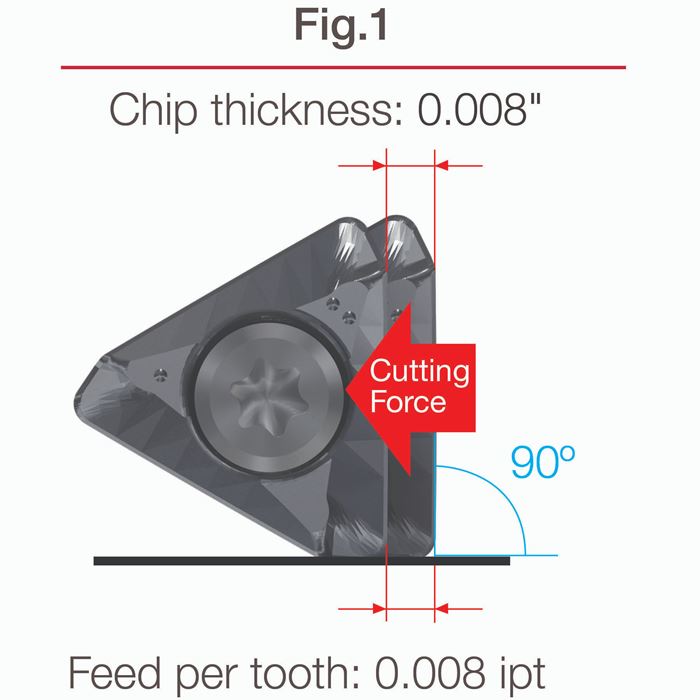

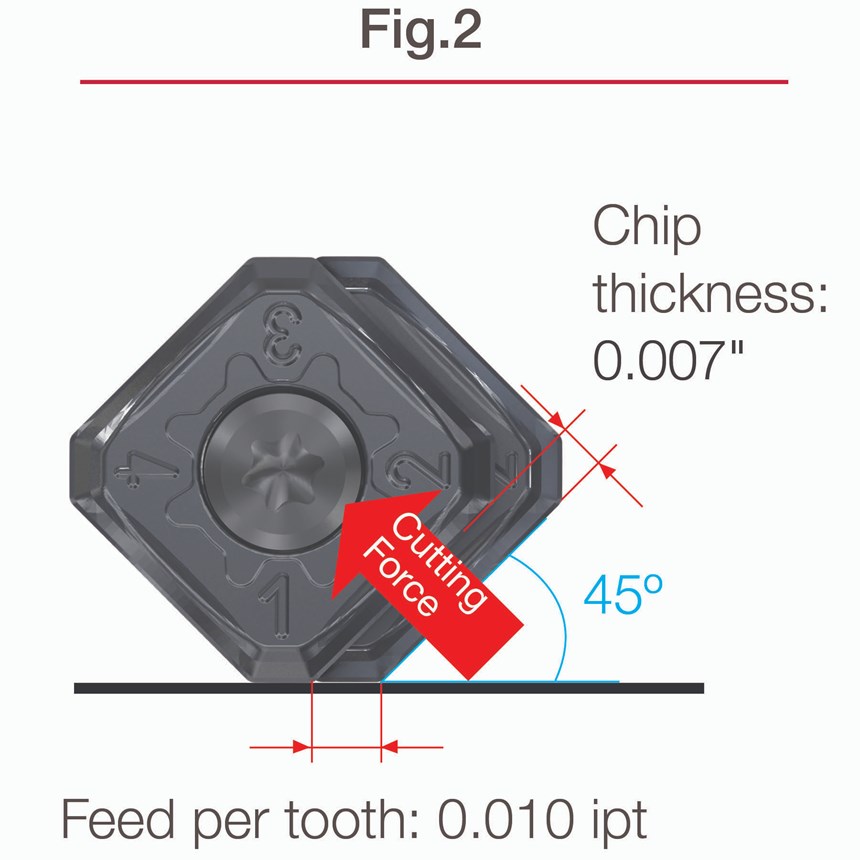

The HFM mechanism is based on the chip thinning principle. Chip thinning depends on the lead angle of a milling cutter. A cutter with a 90-degree lead angle has no benefit of chip thinning, as 0.008-inch of feed per tooth only delivers the same 0.008-inch of chip thickness. In the case of a cutter with a 45-degree lead angle, a 0.01-inch of feed per tooth creates a 0.007-inch of chip thickness, which allows the feed to be increased, resulting in reduced cycle time.

HFM specializes in long-reach applications such as deep-hole and pocket machining. Its ramping capability allows the high-feed cutter to perform helical interpolation (when the tool moves in a circular motion to the X and Y axis, while simultaneously moving downward on the Z axis).

When it comes to large parts, HFM is strong and fast, but machinists must make an additional finishing pass to clean up the rough surface it generates. Today with the incorporation of wiper inserts, HFM cutters can deliver an outstanding surface finish with no reduction in feed rate, improving the efficiency of the overall machining process.

Despite the small depth of cut of HFM, it provides a high metal removal rate, which makes workpiece materials closer to the desired shape in one operation. HFM can often eliminate semi-finishing operations and simplify the finishing process. This characteristic is ideal for 3D machining.

For More Information

Tungaloy America / 630-227-3700 / info@tungaloyamerica.com/ www.tungaloy.com/us /

About The Contributor

Vic Dodd is a product manager for rotating tooling for Tungaloy America.

Related Content

-

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

-

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

-

Tolerancing in Mold Design, Overcoming Cutting Tool Vibration, SPE MTD Updates & More Most-Viewed May Content

Every month, MMT draws inspiration from its diverse readership's wide-ranging interests, from mold design tolerancing to cutting tools and beyond. Here are May’s top 10 most-viewed articles, based on Google Analytics.

.png;maxWidth=300;quality=90)