MMT Chats: COVID-19 Highlights Value of Diversification

I sat down with a trio from Decatur Mold Tool & Engineering in North Vernon, Indiana, for a quick chat about their recent COVID-related project and a couple of lessons the team learned.

Diversification and communication

James Caum, Technical Sales Specialist, Trent Wilson, Sales Manager, and Bert Shaw, Technical Sales for Decatur Mold Tool & Engineering joined me for an MMT Chat about their team’s involvement in building tooling for face shields.

Decatur Mold has 115 people on staff. They are the largest mold builder in the state of Indiana with a very diverse portfolio. The team prides itself on its 24-hour, seven-day-a-week service department. The shop is known for tool repairs, quick engineering changes, speedy deliveries, and prototype molds.

“We build several hundred prototype molds a year to help customers develop production tooling or to get parts quickly,” Caum says. The team also builds Class 101 production tooling 1,000-tons and less. Decatur also has nine injection molding presses that it uses primarily for sampling, and some low-volume part runs.

“We are wide open when it comes to moldmaking. We do everything,” Caum says.

They do not focus too heavily on one industry. However, they are heavily automotive in the service department. As far as new molds and prototypes, they are diversified with customers in medical, power tools, appliances, etc.

“Medical is keeping us going right now—respirators, ventilators, headbands, and air purification machines,” Shaw says. “80% of the medical we're doing right now is because of COVID-19.”

For example, Shaw got a call from one of his customers, GE Appliances in Louisville, Kentucky, who was 3D printing headbands that they were attaching to face shields for their employees at Appliance Park and other plants, as well as local hospitals and medical operations. They couldn't keep up with demand by 3D printing them, so they contacted Decatur Mold to build a mold.

GE challenged the Decatur Team to a rapid turnaround because they heard about another shop that built a tool in three days. So, Decatur used its 54 years of moldmaking experience and started its mold build on a Friday afternoon. They were putting plastic in the mold by noon on Monday.

“We built it over the weekend,” Shaw says.

Typically, this mold would be a three- to four-week lead time, but Shaw moved this project ahead of other nonessential jobs and put the shop’s most experienced people on the job.

The biggest challenge in terms of time was the machining and EDM work. The team had to work around the clock and through the weekend.

“The team accepted the challenge and took off with it. They kept the machines going all weekend to ensure the mold was ready to go out on Monday morning,” Shaw says. Management caters a weekly boxed lunch from local restaurants for all employees. They started this when the outbreak occurred to help support other local businesses and to show appreciation to the employees.

The key to getting urgent work like this complete is the team understanding how vital this project is to hundreds of people in the local community.

Wilson says they lead just how compassionate their people are. “We have a group that when humanity needs help, they step up and do whatever necessary,” Shaw says.

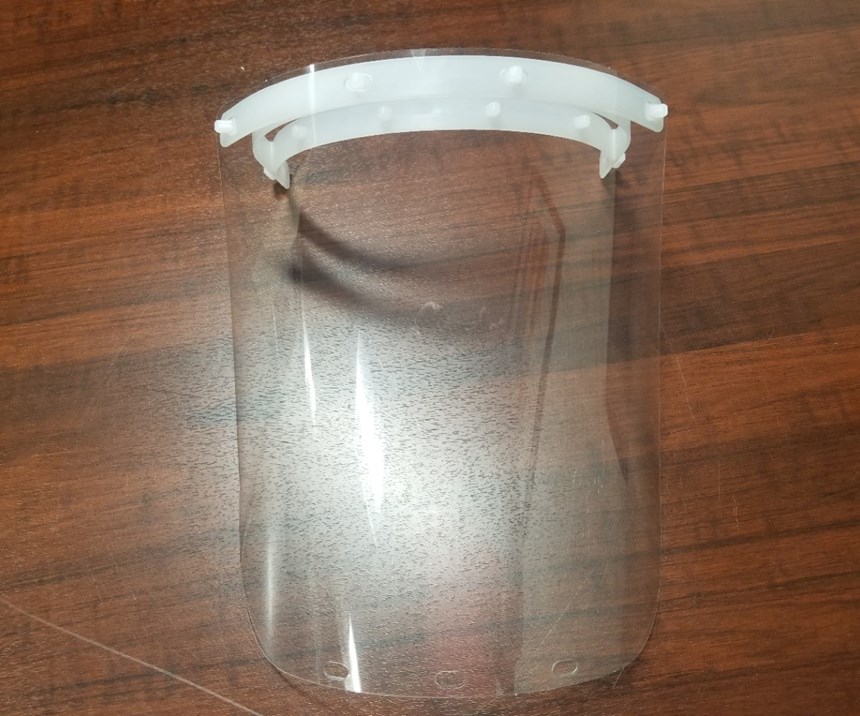

The Decatur reusable face shields are being donated to local hospitals, medical facilities, and human services facilities. And, Decatur’s owner was contacted by the Army for an order of 25 face shields. Decatur designed and built its own mold and donated those shields to the Army.

“It's been ongoing since we built the first mold. We’ve received two or three different headband designs, and seven or eight customers have contacted us to build molds. Plus, a large automotive company decided that they need us to build a two- or four-cavity mold so they can start making headbands as well,” Wilson says.

Caum believes there's going to be a need for face shields for a few more months, maybe through the rest of the year.

“We're still producing shields from our mold, and we’ll continue to donate them to companies in need. They come disassembled, but there are only three components—the band, the face shield, and the strap that holds it to your head,” Shaw says.

As for business, Caum says automotive work has dropped off, but they are still quoting a lot. However, they are doing mainly medical right now.

The key to moving through this crisis, according to Shaw, ramped up communication and information. His biggest concern is a breakout within the shop, so they continue to invest in employee health and safety precautions.

The new normal for Decatur is going to include the continuation of its social distancing efforts, cleanliness and protective measures, and, most importantly, diversification.

“Truthfully, our key to getting through this is making money to pay our people to keep them safe, and we’re doing that with diversification. If you're tied to automotive right now, you’re probably in trouble. We were tied to automotive, but it was only a percentage of our business, and we're capable of pulling through this with the rest of our customers. I believe diversification is always a key for any business,” Wilson says.

Read Next

MMT Chats: COVID, Communication and Customers with CDM Tool & Mfg

CDM Tool & Manufacturing expedited and maximized resources with supplier support to be part of a solution in the fight against the coronavirus.

Read MoreMMT Chats: Fighting COVID-19 with Collaboration

Next Chapter Manufacturing, Muskegon Community College, PCS Company and Concept Molds chat about a coalition they formed to produce face shields to help fight COVID-19.

Read MoreMMT Chats: The Cavalier Tool Army Takes on COVID-19

MoldMaking Technology Editorial Director Christina Fuges chats with Brian Bendig, Tim Galbraith and Brenda Quint of Cavalier Tool & Manufacturing about what it took to take on a hand sanitizer dispenser mold project to help fight COVID-19, as well as the impact of the virus on its business and people.

Read More