Popular Posts: May 2020

Catch up on the five most popular blog posts from May 2020.

It’s the end of May, and you know what that means—Amerimold Connects is right around the corner! For those who haven’t heard yet, this free remote event is the answer to this year’s Amerimold in Novi, MI, being cancelled by bringing the moldmaking community together in a virtual space. Be sure to check it out!

But before we launch into all the great education sessions, virtual exhibitor booth visits and latest technology updates that Amerimold Connects has to offer, let’s take a moment and reflect—by catching up on the most popular articles that readers like you have been reading.

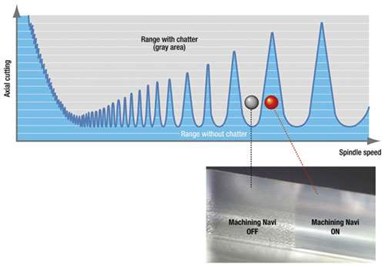

How to Eliminate Chatter

Eliminating chatter is a great way to improve surface finish when performing CNC milling. Control technology detects chatter and automatically adjusts spindle speed to eliminate chatter, thus improving surface finish. Surface finish problems can be profit killers for today’s mold manufacturer. One of the most common causes is chatter created by vibration in the CNC machine tool cutting process. This can lead to higher costs, delayed deliveries and even lost orders due to poor quality. In addition, vibration can cause uneven tool wear, resulting in poor surface finish, geometry inconsistencies and reduced tool life.

Read the complete article here.

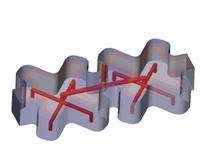

7 Key Advantages of Hot Runner Systems

The runnerless molding of thermoplastics is no longer new - it's been a known technology for more than 50 years, with commercial systems being available for more than 40 years. However, the growth of hot runner system sales during the last decade has been exceptional. This is a direct reflection of improved hot runner technology and of other improvements in heat control

and melt-flow analysis. This growth also is a reflection of a better understanding and acceptance of the benefits of hot runner systems and their application by moldmaking companies and OEMs alike.

Today there are in excess of 40 hot runner systems suppliers as well as a number of moldmakers who design, manufacture and install their own systems in the molds they build. Current systems sales are in the hundreds of millions of dollars and it is not uncommon for the larger commercial hot runner systems suppliers to have sales approaching $50 million or more.

Read the complete article here.

A Virtual Handshake Takes on COVID-19

M.I. Integration does mold building and molding work for some critical automotive and defense industry projects. Still, as the virus hit, the injection molding facility was shut down, temporarily laying off all the employees. With its top priorities being the health and safety of its people and the financial health of the company, M.I. management focused on managing its cash flow properly and connecting to all available government aid to minimize the impact on its workforce.

Read the complete article here.

Related Content

How to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More