This month’s product roundup focuses on some of the surface treatment services and technologies being offered to the moldmaking industry, and includes some prominent companies such as:

- Alliance Specialties and Laser Sales

- PCS Company

- DW Sales

- Slide Products

MMT publishs new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar. Follow each title link below for the full product post.

For digital-only products posted this month read “Technology Roundup: Moldmaking Product Highlights.”

Surface Treatment

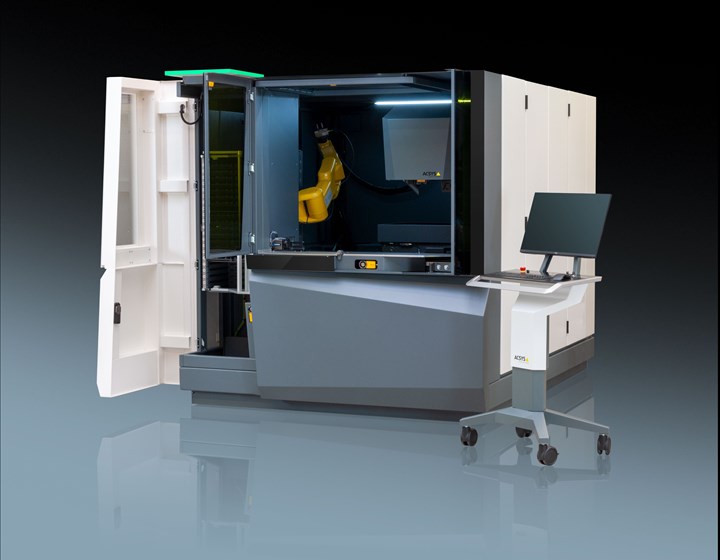

ACSYS Lasertechnik introduces Multishift, a fully automatic laser system with Industry 4.0 integration. Multishift is suitable for applications in medical, automotive, tooling, minting and jewelry, and is said to offer advanced laser marking, structuring, cutting and engraving capabilities, as well as a range of automated features.

For example, featuring OCR (Optical Character Recognition) and OPR (Optical Parts Recognition), Multishift provides operators more complete, accurate and hands-free laser processing capabilities.

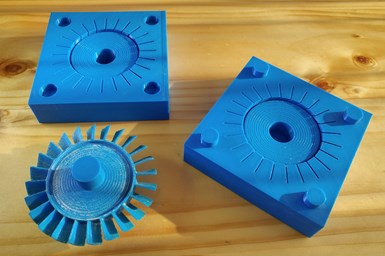

Ultra Polishing has expanded its 34-year experience in mold and machined-parts polishing into offering services for polishing 3D-printed plastic molds and parts and printed metals. By adding this capability to its repertoire, the company hopes to provide a readily available service to additive manufacturing (AM) companies that are creating new products via complex dimensions and unconventional materials that require polishing for the mold or part to properly function.

Alliance Specialties and Laser Sales is introducing its newest engraving system, the Leviathan. Said to match the versatility of its biblical namesake, the IPG Fiber Laser System is a free-standing, portable, completely open system, with 360-degree rotation and high flexibility. Built to handle larger, more functional work in critical areas, Alliance says its system provides greater accessibility to more difficult, harder-to-reach areas, and eliminates the deconstruction of a mold that would typically be sent out for repair or simple maintenance.

Made for moldmakers, mold maintenance technicians or anyone working with metal materials, Slide Products’ Copper Anti-Seize Compound is said to dramatically lower friction and torque between metal components, protecting against high heat and corrosion. Formulated with a higher amount of metallic solids than other compounds, it is heat stable up to 1,800ºF/982ºC.

Copper Anti-Seize Compound is compatible with most metals and plastics. It helps technicians reuse damaged or threaded parts and will not harden, drip or separate.

Rocklin Manufacturing introduces MobiLase, an all-in-one, portable fiber laser marking unit housed in a 45-lb rolling suitcase. While laser marking units are typically large, heavy, stationary machines, Rocklin says its lightweight MobiLase enables industrial strength laser marking to be taken directly to the part—versus a laser marking station—and completed anywhere. The innovation reportedly eliminates costly downtime and investments in elaborate contraptions to mark large parts.

Xebec Deburring Technologies’ ceramic fiber brushes are ideal for deburring, cutter mark removal and polishing of molds following the milling process. They can be used like a cutting tool in a CNC or robotic machine for fast, automated deburring. In a recent test performed on a NAK Steel Mold part, Xebec found that an automated finishing solution with Xebec Brush was 57 times faster than manual methods performed by skilled workers.

The Ultramax DF ultrasonic system from PCS Company is a dual-function unit that gives the versatility of both ultrasonic and mechanical polishing. Short stroke and fast reciprocation provides complete control over the most demanding polishing and deburring tasks. Control functions, such as an adjustable stroke length between 4-40 microns enable users to polish right up to the wall, or finish to an edge.

DW Sales has recently added three new fine grits—1,500, 2,000 and 3,000—to its Ceramic Super Stones range for semi-finishing, final finishing and mirror polishing. Available to the moldmaking industry for more than 20 years, DW Sales says Ceramic Super Stones are ideal for fine detail polishing. Strong and flexible, they are non-loading for use on all metals types, and are said to be thin enough for use in tight ribs and slots.