For February’s product/service roundup, MoldMaking Technology focused on companies that offer mold repair and surface treatment products and/or services, with the addition of a few miscellaneous categories (cutting tools, hot runners and mold components). Catch a glimpse of what you might see in MMT’s February 2021 print issue and digital issue below (find all archived and recent digital issue versions here on the 1st of each new month).

Never seen some of these before? We publish new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar for a more streamlined approach. Follow each title link for the full product post.

View January’s technology roundup here.

Alliance Specialties and Laser Sales released the Alliance ID-1 Fiber Laser Welding System to meet needs for a fiber laser system with a smaller footprint and a lower price point. Built in the U.S., the ID-1 Fixed Workstation is a 300- or 450-watt fiber laser welding system engineered for companies needing to repair inserts, components and smaller tooling.

The Rocklin Manufacturing Co. MoldMender Micro Welder delivers simple and cost-effective mold and die repair in-house through a low heat, non-arcing welding process.

Mold and die repairs are accomplished by producing interlinking spot welds to totally bond the repair material to the desired area of the work piece. A simple process of rolling the electrode permanently bonds the welding material to the workpiece, resulting in a consistent quality weld with minimal heat. No welding experience is necessary.

High Tech Laser & Polishing’s (HTL&P) wide range of services assist customers with mold surface repair projects while saving on shipping costs and lead times. The one-stop shop is ideal for laser welding, polishing and laser engraving amenities

Under its laser welding offers, HTL&P can perform engraving, texturing, etching, cutting, annealing, drilling and welding services. High Tech also offers a versatile service offering under polishing.

The FiberStar Series manual laser welding systems for precision welding operations from LaserStar Technologies Corp. are ideal for a variety of common welding applications. This includes plastic injection mold, dies and tooling repair, complex electronic components, high-precision industrial assemblies, pressure-sensitive hermetic laser sealing and more.

The company covers both the FiberStar 8800 Open Laser Welding Workstation and the FiberStar 8900 CNC Welding Workstation; both products can spot, seam, repair, laser welding, micro and battery weld a variety of materials.

Service provider Precision Laser Technology (PLT) supports global mold builders with a wide range of laser services including texturing, engraving, welding and direct part marking. PLT also offers laser and Micro-TIG applications and staffs an experienced team knowledgeable in a wide range of tooling metals, alloys and corresponding fillet wires.

PLT offers mold engraving, Direct Part Making (DPM) and laser deposit welding services.

Laser Welder Achieves Wide-Range, In-House Repairs

The Sunstone Combo 200 Laser by Sunstone Welders is a 200-J laser welder specifically designed for the repair of molds and dies, ensuring the avoidance of expensive repairs and costly revenue losses. Attached to a swing arm, the Sunstone 200 Combo can reach a majority of locations, even the largest of molds or dies, and is able to make repairs without removing or relocating the mold. The unit’s flexibility and power range make it the ideal tool for in-house repairs.

Plate-out, oxidation and stains on fine tooling surfaces can now be removed safely, quickly and cost-effectively with a new Mold Polish from Slide Products, Inc. Ideal for all types of metal molds, Slide Mold Polish restores surface finish, while providing a high luster sheen. The non-hazardous and non-corrosive polish also possesses a very low VOC count for safer environmental use.

NSK America Corp. has upgraded its Ultrasonic Polisher with the advanced-performance Sheenus ZERO. The polisher quickly removes hard layers of EDM deposits and polishes difficult areas such as complex corners and ribs. It can be used for deburring, grinding and polishing on ferrous and non-ferrous materials.

Enhanced features include an improved user-friendly design and high efficiency power, offering variable amplitude between 19-29 kHz per second and the production of minimal hand vibration.

Grieve Corp. introduces No. 862, a gas-heated 2000°F (~1093.3°C) furnace currently used for preheating molds. The furnace has 750,000 British Thermal Units per hour (BTUh) installed in four modulating natural gas burners with a floor-mounted combustion air blower. Workspace dimensions are 36 inches wide x 48 inches deep x 36 inches high.

Controls onboard No. 862 include an automatic door switch to drive burners to low fire when the door is opened and an air-operated vertical lift door.

BORIDE Engineered Abrasives has extended its Ceramic Super Stones line to include three new fine grits with ratings of 1,500, 2,000 and 3,000. The company advertises these new entires for semi-finishing, final finishing and mirror polishing on molds and dies, saying they result in a smooth polished surface and excellent polishing results.

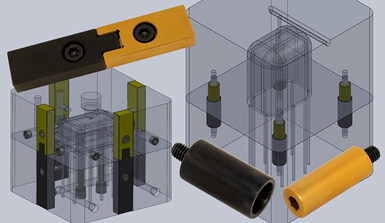

Progressive Components continues to introduce new mold component styles and sizes in order to meet every application need. This includes the expansion of its alignment lock product line with the Cavity, Flat Cavity and Round Cavity Interlocks for precise alignment.

Eliminating installation of mold base locks, for example, the Cavity Interlocks mount directly into the mold's inserts. Sized for nominal plate and insert thicknesses, the highest amount of locking surface is provided for the minimum amount of space to be machined.

Tungaloy has expanded its popular DrillMeister range of exchangeable-head drills to include the new, DMH drill head with enhanced cutting-edge geometry.

DrillMeister incorporates a self-locking interface that enables simple and secure drill head exchange. Since drill heads can be replaced without having to remove the drill body from the spindle tool, setup time can significantly be reduced, eliminating presetting, offset and touch off of the replaced tool.

The Hasco nozzle range has recently been extended with the highly-efficient, and low-cost, Single Shot H6300 nozzle series. In developing the new series, Hasco’s focus was on compatible installation dimensions, optimum temperature control, functionality and a cost-optimized design. The many different nozzle variants are said to allow a straightforward feed into a sub-runner or direct gating to the molded part.

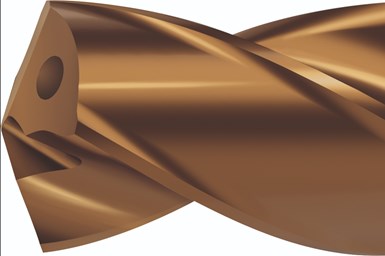

Tooling company Walter USA announces an addition to two product ranges— its DC160 Advance drill range and CBN insert grades—that the company says will benefit both deep-hole drilling and turning. The solid carbide Xtreme Evo drills now extends to capacities of 16-30 times diameter and offer deep-hole drilling without the need for pecking, and new CBN insert grades for ISO K and H materials complete the company’s extensive CBN turning range.

Walter’s DC160 Xtreme Evo drills feature optimized coating and geometry and a thinner web with a 140° point angle, ensuring increased positioning accuracy and reduced centralized cutting forces.

For turning, the new CBN indexable insert grades for ISO H and ISO K materials are WBK20 for finishing cast iron and WBK30 for high metal removal rates in ISO H, and for finishing with a heavily interrupted cut.

.png;maxWidth=300;quality=90)