The Byrne Tool + Design team found that its new five-axis DMU monoBLOCK was so much more efficient that it reduced setups, enabled more lights-out machining and delivered double the uptime per week versus older three-axis machines. Plus, the DMU monoBLOCK required no service calls other than basic maintenance in the first four years Byrne owned it. As a result, given that productivity boost, the company ordered another nearly identical machine last year. Photo Credit: DMG MORI

In its 48th year, injection toolmaker Byrne Tool + Design Inc. shows no signs of slowing down. The company, which makes up to 200 small- and medium-sized molds per year with a lean team of just 24, sees plenty of opportunities ahead. Byrne Tool supports a well-rounded client base from automotive, office furniture, electrical, consumer goods, medical, recreational vehicles, oil and gas and government. It focuses on producing steel tooling — the majority of which is straight injection or overmolding with some gas-assist — for presses sized from 20-700 tons. Byrne describes itself as a “full-service innovation house that brings ideas to reality.”

In addition to providing part and tool design for injection molding, the company also designs products produced via extrusion, metal forming, and die casting. These traditional manufacturing competencies are supported by polymer additive manufacturing for prototypes, rapid tooling and end-use components, including end of arm tooling (EOAT). Additionally, Byrne offers mold maintenance and repair and engineering changes for any customer’s injection tooling. It conducts mold tryouts next door at its sister facility, Byrne Electrical Specialists Inc., a 51-year-old injection molder supplying electrical components to the consumer, automotive, building/construction and office furniture markets with facilities in Michigan, Mexico and China.

For the last eight years, Byrne Tool has supported its traditional manufacturing capabilities with polymer additive manufacturing for prototypes, rapid tooling and end-use components, including end of arm tooling (EOAT). Photo Credit: Byrne Tool + Design Inc.

In fact, through its Asian partner, Byrne Tool acts as a landing house for offshore tools being fitted to run in North America. These capabilities help the team compete globally, quickly and effectively adapt to changing customer needs and provide parts “on time and right the first time.” As Andy Baker, Byrne Tool quoting and design engineering manager, adds, “We are Byrne Tool plus so much more.”

Upgrading to Five-Axis

In 2017, Byrne Tool was quite busy and decided to invest in a five-axis CNC machine. All the machining centers the company had installed at the time were either three- or four-axis. The team hoped that moving to a five-axis machine could reduce the number of setups required per workpiece and the time involved in those setups to keep the company globally competitive. The team looked at options from three companies — one from whom they’d previously purchased several three-axis machines. They also attended trade shows and visited machinery OEM showrooms, and they even visited fellow moldmakers in the area to see different equipment in use.

“We do a lot of lights-out machining, so we were concerned about two things: being able to run the new machine unattended more of the time — as we probably run lights out as much as we do when we’re here — and we hoped that having an accurate machine with fewer setups, we could better blend our machining on all five sides of the block without us needing to be there to manually shift the block,” Mike Bensted, Byrne Tool CNC department lead, explains.

The new DMU monoBLOCK (left) and the new one (middle) are shown above. In front of the machine are (left to right) Joshua Kris, DMG MORI USA; Mike Benstedt, Jill Maksimowski (company accountant); and Andy Baker from Byrne Tool. Photo credit: DMG MORI

“We also knew we wanted a high-end machine and DMG MORI is very popular in West Michigan,” Baker continues. “We liked the features the company offered, the compact footprint, the size and visibility of the worktable and how easy it is to load even large blocks into the machine without fighting the machine or banging it up. We also liked that DMG had a technical center close by for quick support should we need it.”

Byrne eventually ordered what at the time was a DMU 85 monoBLOCK five-axis machining center with a 60-toolchanger and Heidenhain controls. The machining center can hold up to a 2,200-pound/998-kilogram block and has a maximum travel of 37.4 inches/950 millimeters on the X-axis, 33.5 inches/851 millimeters on the Y-axis and 25.6 inches/650 millimeters in the Z-axis with a maximum workpiece height of 23.2 inches/589 millimeters and a diameter of 40.9 inches/1,039 millimeters.

“Our five-axis monoBLOCK was still a big part of being able to turn a steel tool around in such a short amount of time. That machine runs with twice the uptime as our older machines, and it gives us the flexibility to do what we want to do and run much of the time lights out. In addition, its efficiency really helps us stay competitive in the global market, which is why we invested in a second one last year.”

The equipment was installed in Q3 2017. Byrne immediately used it for rough and finish machining and even for gundrilling its waterlines/cooling holes and locator pins — everything, except turning and machining electrodes. Although they didn’t remove any of their older machines, the team noticed a difference in productivity.

“Everything we did was so much more efficient on that machine,” Bensted recalls. “Whereas before we needed six different setups on our three-axis machines, with the five-sided machining capability of the monoBLOCK, we could accomplish the same thing in just two setups, which saved us a ton of time. When we charted out our OEE [overall equipment effectiveness] values between our three-axis machines and our five-axis monoBLOCK, we saw we ran the monoBLOCK twice as much on a weekly average.”

“Even better, during the first four years we owned it, our monoBLOCK ran well and didn’t need any service calls other than basic maintenance,” Baker adds. “That kind of uptime helps increase our productivity and keeps us globally competitive.”

The speed, productivity gains and high uptime that the first DMU monoBLOCK brought convinced the company to purchase and install a second nearly identical machine (now called DMU 95 monoBLOCK) last fall.

Mike Bensted checks on the progress of a tool being cut in the DMU monoBLOCK.

Photo Credit: Byrne Tool + Design Inc.

Stiff, Stable, Fast, Cost-Effective

DMG MORI Ltd. is a global manufacturer of machine tools, integrated automation and “end-to-end” digital solutions that support and extend the company’s core competency in turning and milling machines. Modular product design enables easy, fast, scalable entry into digital manufacturing and end-to-end digitization, and customer support services — including training, repair/maintenance and spare-parts services — cover DMG MORI machine tools throughout their entire life cycle. The company supports a global base of 100,000 customers in 55 industries and 87 countries with 12,000 employees, 16 production plants and 111 sales/service locations.

First introduced around 2011, the DMU monoBLOCK is the company’s best-selling five-axis product line, with 600 to 1,000 units sold per year and over 5,000 units in the field. All DMU monoBLOCK machining centers are produced at the Excellence Factory in Pfronten, Germany. The 85/95 models that Byrne purchased are the mid-size machines and there are two smaller and two larger models as well. All DMU monoBLOCK machines offer the option of 60 or 120 toolchangers and either Siemens or Heidenhain controls.

Several features make the DMU monoBLOCK noteworthy. First, the entire machine bed is a single large casting with three-point support. This makes the machine extremely stiff and stable, enabling it to run very high feeds and spindle speeds of up to 20,000 rpm at up to 70 horsepower with high accuracy while achieving fine surface finishes. The company says this performance is unrivaled in this class of CNC machine and can help toolmakers reduce machining time by 25% or more.

“With the right cutter and program, DMU monoBLOCKs can achieve lens-quality finishes. It’s a real advantage to be able to hide visual steps and blemishes. In fact, it also significantly reduces secondary process time to bench and polish, leading to overall time savings.”

Despite its stability and performance, DMU monoBLOCK machines are known for their compact footprint and the number of desirable features they sport as part of a standard package. Additionally, they feature an ergonomic design that puts the toolchanger, worktable and controller all within arm’s reach and at waist height, so machinists don’t have to bend over to check settings or install or remove workpieces. A large safety glass door encloses the front of the machine and provides a high level of visibility. The machine can be loaded from the front, but larger blocks can also be lowered via an overhead hoist from above.

“When you’re machining molds in a traditional vertical machining center, you end up having to flip the workpiece three to four times to drill water lines and other holes on the various sides of the block,” explains Joshua Kris, DMG MORI USA area sales manager – Michigan Region/Grand Rapids Technical Center. “Byrne Tool was looking to reduce those setups and increase their productivity, so they were initially attracted to the DMU monoBLOCK for its speed, accuracy and reliability. However, Byrne Tool is known for its products’ quality, state-of-the-art finishes and finish benching and polishing, so they were also interested in the high surface finish DMU monoBLOCK machines can achieve. With the right cutter and program, DMU monoBLOCKs can achieve lens-quality finishes. In addition, it’s a real advantage to be able to hide visual steps and blemishes. It also significantly reduces secondary process time to bench and polish, leading to overall time savings.”

Here is Byrne Tool + Design’s CNC programming area. Everyone works side by side, making it easier to collaborate and train younger team members. Photo Credit: Byrne Tool + Design Inc.

From Weeks to Days

The speed, accuracy and efficiency of Byrne Tool’s first DMU monoBLOCK machine enabled the company to pivot during the early phase of the pandemic in 2020 and design and build a tool to mold personal protective equipment (PPE) in just five days rather than the five to six weeks that typically would entail.

“During the pandemic, we easily made a dozen medical tools, but the best was a face shield mold whose headpiece we designed ourselves, produced a tool for and handed off to our sister division to begin molding and assembling in just five days,” Baker says. “We donated quite a few of those pieces.” He acknowledges that this was a unique time when most other work had stopped at most moldmakers, making it easier to focus on production of the two-cavity mold, which required no side action and wasn’t annealed, so treated as more of a prototype tool.

“Our five-axis monoBLOCK was still a big part of being able to turn a steel tool around in such a short amount of time,” Bensted adds. “That machine runs with twice the uptime as our older machines, and it gives us the flexibility to do what we want to do and run much of the time lights out. In addition, its efficiency really helps us stay competitive in the global market, which is why we invested in a second one last year.”

Related Content

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreRead Next

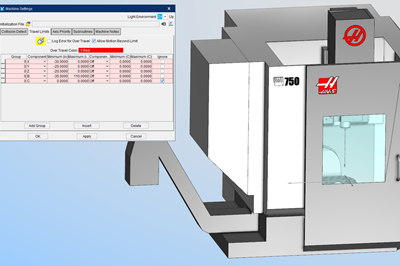

CNC Machine Simulation Software Supports 3D Interface to Verify, Simulate and Optimize NC Programs

CGTech’s Vericut software can now read in GDML files with 3DLive, which enables users to easily obtain machine-specific information and manually build digital twin machines.

Read MoreMoldmaking In the Heart of Europe

Culture, technology investment and industry involvement make this small Slovenian mold builder globally competitive despite a skills gap and rising labor costs.

Read MorePutting Design in the Driver’s Seat

Being an engineering-driven mold manufacturer has dramatically impacted this shop’s efforts to automate processes, develop its workforce and expand into new types of business.

Read More

.jpg;width=70;height=70;mode=crop)

.JPG;maxWidth=150;quality=70)

.JPG;maxWidth=400;quality=70)