Share

Read Next

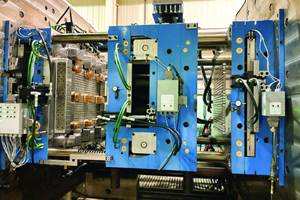

Jatco manager Nate Thomas inspects an injection mold prior to modification. Photo Credit, all images: Jatco Machine & Tool Inc.

Who is Jatco?

Ed Sikora, Owner: Jatco was started in 1957 as a tool and die company. I acquired the company in 1978 and the company’s work and focus shifted to injection mold work as plastics grew. Today, we design, build and repair thermoplastic and thermoset injection molds. We have also expanded our services to include laser welding and industrial laser engraving.

In addition to working with most major industries (medical, consumer goods and automotive), we have strong connections with resin suppliers and R&D departments. These connections provide us with many opportunities to build prototypes. We are mainly well known for our expertise with soft-grip technology, in-mold decorating, insert molds and two-shot molds.

What is your background and what do you view as your chief competitive advantage(s)?

Sikora: I have a mechanical engineering degree from the University of Pittsburgh and have been involved with plastics and tooling my entire career. I began as a development engineer with what is now Nova Chemicals and have remained at the forefront of the industry for over 40 years as owner of Jatco. Since Jatco was a precision machining company, the combination of my experience and existing machining skills provides an excellent base for building great molds.

I have also published various papers in several trade publications. I am a longtime member of the Society of Plastics Engineers (SPE) and currently serve as executive director of the Pittsburgh Chapter of the National Tooling and Machining Association (NTMA). I also speak regularly at events promoting manufacturing careers and workforce development.

Tamper-evident cap mold redesigned by Jatco. Mold elements are now accessible from the outside of the mold. This mold design provided a 90% reduction in the time required to change the mold elements.

Share an example of a significant recent change in your use of technology.

Sikora: Jatco upgraded its machining technology and provided in-house training to become even more well-versed in hard milling, drilling and tapping tool steels with hardness up to 62 Rc and high-speed milling technologies. Our new equipment has turn/mill capabilities which allow the machining of complex mold components in one setup.

Share a change in your general approach to business.

Sikora: We updated our website, completed our ISO registration and developed our social media presence. Currently, we are working on our cybersecurity certification.

How do you see your business evolving in the next three to five years in technology, business strategies, place in the market, etc.?

Sikora: We continue to upgrade our in-house technology and integrate additive technology. We also combine local expertise with international competitiveness. We have strong partnerships with global tooling suppliers, so we know both U.S.-based and offshore options. With the full knowledge of our customers, we provide project management of offshore mold builds when customers require a lower cost alternative. We have a growing list of partnerships in China, Taiwan, India and Portugal.

Our team helps customers navigate the confusion of countless offshore tooling options to ensure that they get the best quality at a great price. Our global tooling service includes subcontracting the mold construction to a partner mold shop. This work consists of initiating the design process and maintaining all drawing files; ensuring U.S. standards are applied for all mold components; ensuring all steel is supplied, certified and heat-treated by leading tool steel suppliers; overseeing mold construction; providing on-site inspections when required; simplifying all import and tariff procedures; and delivering support and maintenance.

We continue to upgrade our in-house technology and integrate additive technology. We also provide local expertise with international competitiveness.

How are you addressing the skills gap in the industry?

Sikora: Southwestern Pennsylvania is an interesting region when it comes to moldmaking. Jatco and one other company are the only standalone injection mold builders in Pittsburgh. While moldmaking is limited in the area, die-making and precision machining are alive and well.

Jatco toolmaker Carl Bean with apprentice Zaiah Zieger discuss a turning project with a special alloy.

To fill the gap, we have a Pennsylvania-registered apprentice training program. We use NIMS credentials to track on-the-job training. In addition, related classroom instruction is available through the Pittsburgh Chapter of NTMA’s apprentice program.

I am very involved with the Pittsburgh Chapter NTMA. Pittsburgh is one of the largest NTMA chapters with over 60 member companies. Our two largest members, Oberg and Penn United, each have over 600 employees.

Training has been the focus of the Pittsburgh Chapter for more than 45 years. The chapter provides the related classroom training (144 hours/year) for members and non-member companies with registered apprentice training programs. This four-year program is taught in three different locations across the region.

In addition to apprentice training, the chapter has developed the premier workforce development program in the county.

In addition to apprentice training, the chapter has developed the BotsIQ program, one of the country’s premiere workforce development programs. We participate in BotsIQ as a corporate sponsor and as technical advisors to a local high school robotics program. The programs offered by BotsIQ start with middle school students and continue with internships for manufacturing-focused college students. The BotsIQ programs include Cobot Challenge, High School Combat Robotics, BotsIQ Academy and Close the Loop.

What is the Jatco world mold system?

Sikora: A mold with eight-second insert changes! Our system was developed initially for resin suppliers and compounders and allowed for the standardization of test-specimen molding. Developed in 1989, world molds are a flexible test-mold system designed to comply with the internationally accepted ISO standards.

Jatco’s flexible test-mold system.

The heart of the world mold system is the main frame, which installs in the injection molding machine. We supply our world mold frames using pre-hard 420SS. The frame contains the main ejection system, water brackets and quick-release levers.

The significant advantage is speed. A typical world mold insert can be changed in as little as eight seconds, eliminating the need for material purging. In addition, the system can be further optimized using a separate water pre-heat station.

Describe the most interesting/notable mold project your company was awarded.

Sikora: A customer needed a new mold to produce tamper-evident plastic caps. The customer uses the mold to make eight caps the same size but with different logos for the companies they supplied. The caps are made with a single color of polyacetal, an engineering-grade thermoplastic used in precision parts requiring high stiffness, low friction and excellent dimensional stability.

Insert molding samples made using Jatco molds. Products include consumer, medical and industrial parts.

While perfectly functional, the mold’s original design required 1.5 hours to take apart and change the mold elements that formed the logos on the caps. We redesigned the mold so the components could be accessed from the outside of the mold instead of taking it apart.

In addition, the changes to the mold, which weighs about 500 pounds, can be made with an Allen wrench. This new, improved design provided a 90% reduction in the time required to change— from 1.5 hours to less than five minutes. The decrease in time means that the supplier will be able to use the time saved for other projects, make smaller runs to reduce inventory and provide quick changes if needed for emergency runs.

Related Content

High-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read MoreInnovation, Diversification and Integration Guide Mold Builder Growth

Quality Tool and Die team discusses the journey from a small automotive tool shop to a diversified full-service moldmaking and plastic production facility.

Read MorePennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

Read MoreOpenness to New Manufacturing Techniques Gives Mayer Tool & Engineering a Competitive Edge

This Michigan mold builder adapts, problem solves, brainstorms and collaborates to exceed customer expectations.

Read MoreRead Next

Midwestern Advanced Manufacturing Design Technology Program Presents Unlimited Career Possibilities

Advanced Manufacturing Design Technology program at Central Community College offers new facility expansion and 100 years of instructor experience to mentor students from drafting, manual machines and CNC to part, mold and die design and advanced machining.

Read MoreNew Ownership Revitalizes Precision Mold Builder with Heavy Capital Investments, New Management Style

A rich history in mold building, recent technology investment and a shift in management philosophy re-energizes a Midwest precision mold builder and contract CNC machine shop.

Read MoreTop Grade Molds Is All About Innovation and Collaboration

Top Grade Molds develops technology solutions with a heavy emphasis on R&D, recyclable material trends and collaboration.

Read More