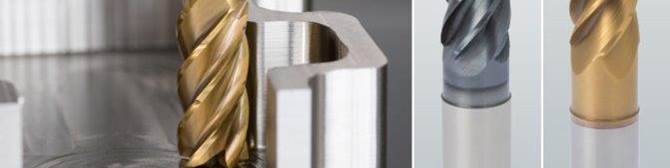

Solid carbide end mills with unique geometry and chip breakers designed specifically for trochoidal milling. Photo Credit, all images: Emuge-Franken USA

Mold builders encounter various milling applications where using the correct end mill is essential for success. Deciding which end mill to use depends on the current stage of a mold’s manufacturing process and the material and features you are milling. For example, are you removing a large volume of material during the roughing process or are you working on a pre-roughed part shape that has returned from heat treatment for final surface finishing?

Here, we review some challenges and tips for your milling tool selection process in five key areas of mold machining.

1. Pre-Roughing Stage

When removing a large volume of material during pre-roughing, a trochoidal-style toolpath strategy may be the best solution. Trochoidal milling for difficult, hard materials and thin-walled areas involves overlapping circular cutting paths with linear movement. The small contact angle on a trochoidal end mill reduces heat generation during machining and promotes less thermal stress, increasing tool life.

The end mill is fully utilized over the entire flute length, resulting in wear evenly spaced over the full cutting edge, contributing to longer tool life. It also generates high metal removal rates (MRR) on low-powered machines and trochoidal-style slot milling reduces wear. Suitable end mills provide increased MRR of more than 30%, fewer tool paths, longer tool life and a high axial depth of cut of up to 4×D.

Hard-cut end mills are a good solution for finishing hard materials up to 66 HRC.

Trochoidal milling is an advanced strategy and the tools work in tandem with modern CAM software to optimize the calculation of milling paths and avoid unproductive tool motion. The basic trochoidal toolpath concept generated by different CAD/CAM software is relatively the same, providing full flute depth engagement with light radial stepover values using climb-cut circular motions to mill out sections of material quickly.

Trochoidal tools are also especially useful when machining the mold base, providing the framework for the mold cavity and assembling the components such as inserts. Removing chips from deep pockets is critical for cutting tool performance. Milling a pocket at a 4×D diameter without the chip-breaking feature will produce chips as long as the length of the cut that will wrap around the cutting tool, breaking the cutting edges.

Trochoidal tools with an engineered chip-breaking feature that breaks into small portions along the long flute’s length of cut improve chip evacuation and yield smooth vertical wall finishes for deep pockets in cores and cavities, side-action pockets and other features that require a 3×D, 4×D to 5×D depth of cut.

2. Hard Milling

The right end mills, cutting parameters, machining process, toolholding and workpiece clamping are critical when hard milling materials up to 66 HRC. However, with the proper setup, mold builders can accurately machine challenging features and greatly minimize or eliminate time-consuming grinding and polishing rework.

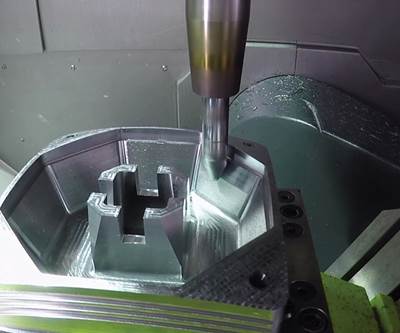

Pre-roughed mold is back from heat treatment and is set up in a repeatable fixture for a final finish of the outer profile.

The ideal end mill for hard milling requires a precisely matched tool design to the solid carbide material. For example, a solid carbide tool substrate with high-heat hardness and toughness are desirable characteristics for higher wear resistance, along with a coating for heat protection.

Cutting edge strength depends on many factors, such as micro features on a cutting tool designed with high cutting edge stability and a solid carbide substrate.

For hard finish milling, a high level of concentricity is critical in the cutting tool design and the toolholder should be of an equal or better level of accuracy. Cutting tool concentricity that does not exceed 5 microns extends tool life and promotes mold surface finish quality.

A hard cut end mill and a supporting toolpath concept is a good solution for hard milling molds during any stage of the moldmaking process. Hard cut end mills feature an increased core diameter, creating stable roughing and finishing conditions with higher cutting edges, enabling high feed rates. These cutting tools also feature an uneven pitch and a chip former on the peripheral cutting edge.

Hard cut end mills using a trochoidal strategy are also ideal for demanding conditions to maintain mold stability, whether it’s a mold repair, modification or design change after the mold has been hardened — such as adding a support rib or insert to modify a feature or adding a runner.

3. Steep Walls

A challenging step in the moldmaking process is milling a pre-roughed feature that has returned from heat treatment ready for finishing, especially when steep wall features exist.

Tapered circle segment end mills reduce milling cycle time by up to 90%.

For example, when finishing a mold with ball mills on a five-axis machine, the setup provides options to tip the mold in positions that enable the cutting tools and toolholders to access machinable areas with short projection tools and holders. Using shorter tools permits more aggressive speeds and feeds and minimizes chatter and breakage and the tipping abilities of the five-axis machine keep the ball mill off the center portion.

Another example is five-axis finish machining a steep wall using highly productive tapered or circle segment cutting tools (conical barrel cutters). Circle segment end mills achieve an excellent surface finish by mapping only a part of the circle (a circle segment) on the end mill. This end mill design features unique forms with large profile radii in the cutting area of the end mills to enable large stepovers that cut much wider swaths of material and fewer tool passes while maximizing tool life efficiency and minimizing cusps.

Hard cut end mills using a trochoidal strategy are also ideal for demanding conditions to maintain mold stability, whether it's a mold repair, modification or design change after the mold has been hardened.

The large stepover produces higher cutting forces than standard ball nose cutters due to the large radii on both the face and radial cutting edges. By combining advanced cutting-edge geometries with expansive radius profiles, circle segment end mills mimic large-diameter cutter profiles with standard tooling sizes. For example, a 16-millimeter-diameter end mill can have a 500-millimeter radius profile, significantly increasing the stepover width of the end mill and reducing the milling cycle time by up to 90%.

However, those who use three-axis machining to finish this mold will encounter several challenges. First, a longer end mill will be needed to achieve the required access, which makes the tool inherently weaker. To find the ideal ratio of reach and stability, seek a cutting tool designed with stub length of cut and a gradual tapered neck to the shank. Speeds and feeds should also be carefully selected to compensate for the cutting tool's overall length (Note: Always review the cutting tool manufacturer’s recommended feeds and speeds).

A mold builder can also use a modular system with either a screw-on milling head or a replaceable cutting insert placed in a high-speed steel main body. Most versions of this tool system support longer reach due to the main body’s high-speed steel construction, which can impact the level of concentricity because it increases the flexing range.

If pushed too aggressively during machining, this increased flexing range can cause tool deflection and chatter, degrading surface finish quality. Sometimes, extra-long tools require the mold builder to adjust parameters as the machining begins to optimize the cutting process.

4. Tough Materials

Although moldmakers may not frequently encounter challenging materials such as titanium alloys and Inconel, it is still smart to understand the available milling tool options. These materials generate a lot of heat that can raise the temperature of the cutting tool and negatively impact the milling process. This happens because the heat cannot evacuate with the chips and instead remains on the cutter. The goal is to protect the tool from this excess heat.

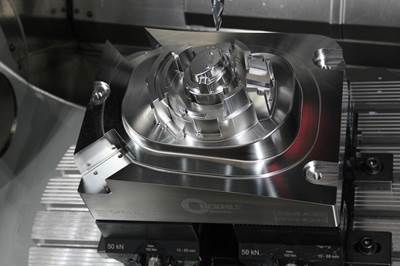

New carbide ball nose and torus end mills are specifically designed for moldmaking.

To do so, consider end mills with a coating that offers good heat protection and a smooth, cutting-edge surface that minimizes chip contact, allowing the chips to fall freely from the cutting tool. On the other hand, chips that cold weld on the cutting tool’s cutting edges increase cutting forces, shortening tool life and possibly causing tool breakage.

For example, ceramic end mills for high temperature-resistant materials can be used for roughing or pre-finishing and produce 2D or 3D contours. These cutting tools are suitable for face, slot, helical, contour and pocket milling. They feature a high-hardness cutting ceramic head brazed to a carbide shank for optimal vibration dampening and longer tool life than one-piece ceramic tools. Featuring a high-feed duplex cutting edge geometry, they produce high metal removal rates in challenging nickel-based alloys, resulting in machining parts 200-400% faster than conventional carbide end mills. Also, tool life is up to five times higher than regular carbide end mills.

5. High-Mix, Low-Volume Work

A final tip for moldmakers who manufacture a low volume of various mold designs is not to go overboard when stocking different types of end mills in your tool crib. There is likely a repeatable pattern for the types of molds and features you manufacture, which helps to determine the types of end mills to stock.

New carbide end mills have a long reach of 8×D that is very useful for deep applications.

Consider multipurpose end mills that are suitable for roughing and finishing, soft milling and some hard milling of up to 50 HRC. For example, end mills made from premium solid micrograin carbide and designed to cut virtually all materials. They feature unique flute and profile geometries optimized for long tool life and superior performance in roughing and finishing applications. Also, variable helix angle flutes provide extensive vibration dampening and are precision ground with advanced edge preparation to maximize chip evacuation.

A chamfer feature protects cutting edges to prevent chipping, and end mills with fully blended corner radiuses extend tool life while providing improved surface finishes. These end mills have an advanced AlCr PVD coating, enabling outstanding performance and extended life in higher operating temperatures. A proprietary sub-micrograin carbide provides maximum abrasion resistance and durability.

Consider these five areas when selecting the proper end mill for your next challenging milling application and seek guidance from an experienced cutting tool supplier.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreRead Next

How a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read MoreRunning Circles Around Milling Challenges

Circle-segment end mills can greatly improve five-axis mold prefinishing and finishing operations.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read More