Running Circles Around Milling Challenges

Circle-segment end mills can greatly improve five-axis mold prefinishing and finishing operations.

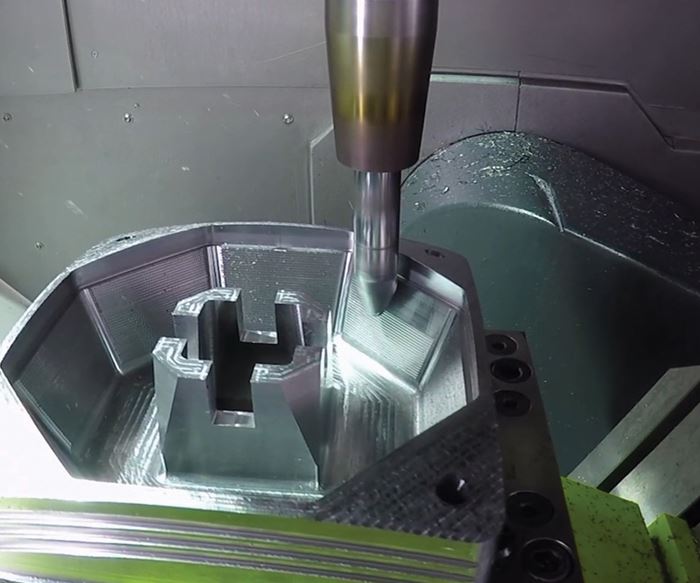

Milling molds with conventional end mills can be time-consuming and wasteful. Tools chip, wear or break, and chatter can lead to poor surface finish and workpiece inaccuracy. Plus, a substantial amount of time is required to remove material via multiple tool passes. To address these problems, a new class of high-performance solid-carbide end mills has been developed. These tools allow manufacturers to achieve optimum levels of machining performance in complex five-axis applications, particularly in moldmaking applications.

Significance of Stepover

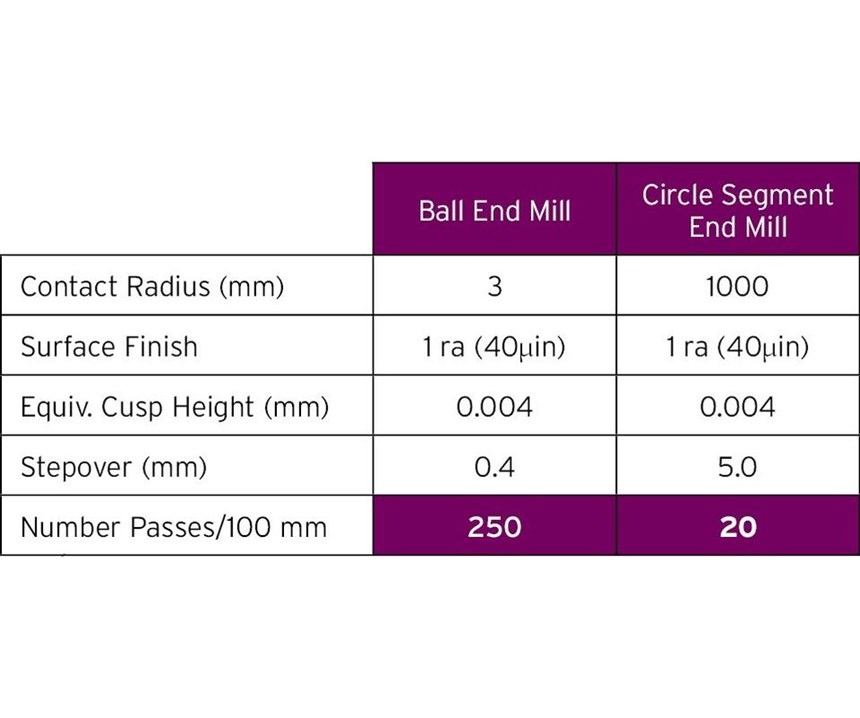

Superior surface finish is one of the key components of a well-made part and one of the biggest challenges to overcome when milling molds. Cutting tool radius and axial depth of cut (also called stepover) are two important factors that determine the surface quality of a workpiece. The larger the stepover, the worse the surface quality gets, and the larger the tool diameter, the better the surface quality becomes at the same stepover.

For example, to achieve a short machining time and fine surface finish using a stepover of 0.19685 inch (5 mm) instead of 0.019685 inch (0.5 mm), the tool radius must be increased substantially. However, the larger tool diameter that would be required would be impractical. One solution to this trying dilemma is mapping only a part of the circle (a circle segment) on the end mill, which will achieve the same machining result. Initial machining trials supported this theory, and an entire series of circle-segment end mills was developed around this solution. These tools provided a significant advantage in five-axis prefinishing and finishing operations.

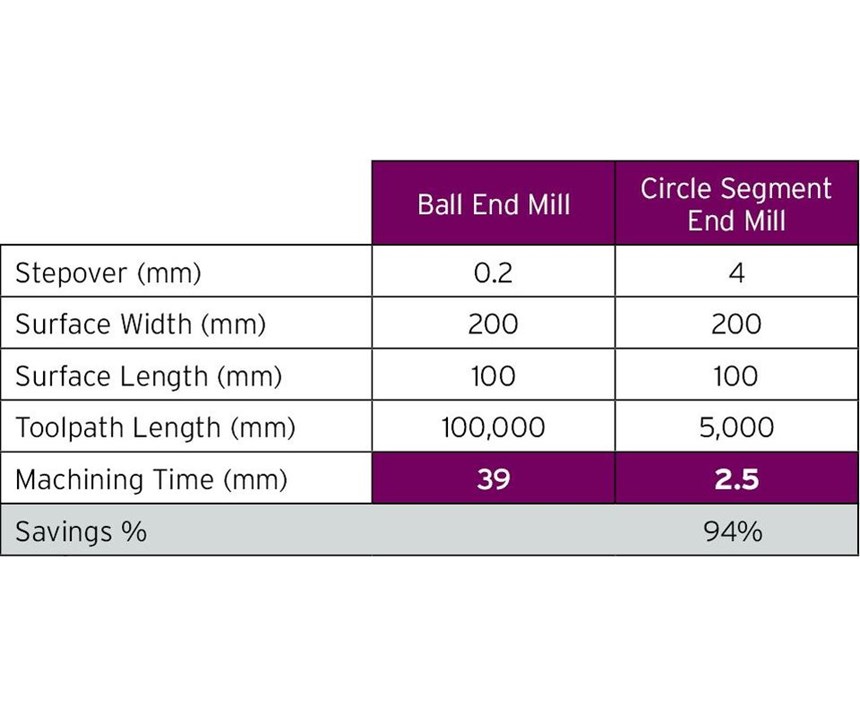

Traditionally, the cutting tools of choice for delivering optimum surface finish were ballnose end mills. However, these types of tools present difficulties when extensive surface finishing is required. Ballnose end mills use small stepover passes to reduce the size of cusps in the material. To obtain the required surface finish, a ballnose end mill’s stepover is generally between 3 and 5 percent of the diameter of the tool, which reduces the amount of surface area in which the tool can be engaged in the material. This means many more passes are required in order to achieve the required surface finish. In contrast, circle-segment end mills use high stepover passes that cut out large areas of material, maximizing efficiency and minimizing cusps. Shorter tool paths increase tool life and produce a higher quality surface finish in a much shorter timeframe.

The cutting area of circle-segment end mills feature large radii, allowing a larger axial depth of cut during prefinishing and finishing operations. This large axial depth of cut generates greater cutting forces than with conventional ballnose cutters. These end mills are designed to enable more material removal with fewer passes in five-axis machining, reducing cycle times and yielding smoother surface finishes, as well as extending tool life and offering substantial savings.

The finishing process is key to reducing cycle time when machining mold and die components that demand high precision, especially for mating surfaces. Many surfaces have to be finished with ball end mills, however, dramatic time reductions can be realized on mold-

lock surfaces, runoff, and lifter pocket walls and floors when using circle-segment tools.

Proof is in the Passes

The true test of success in milling is in the reduction of cycle times and the resulting part quality. An example of an application that demonstrated the advantages of the circle-segment technology was machining of a workpiece measuring 6.3 by 6.3 by 2.2 inches (160 by 160 by 55 mm) with challenging geometries in a prehardened mold steel (P20 steel). The machining required different tools in a total of 14 operations. The average surface finish (Ra) of the workpiece was 0.57 micron, compared to 1.15 microns achieved with conventional ball end mills. In addition, prefinishing and finishing required only about 40 minutes and significantly fewer passes.

Over the last 5-10 years, new CAM software also has been developed to advance roughing techniques that focus on cutter engagement and volume of cut. These techniques use a more complex algorithm than traditional methods, reducing the impact of severe cutting conditions for entry or corner cuts, and resulting in improvements in roughing times of as much as 75 percent. The reduction of roughing times thereby increases the relative time for finishing operations. The right combination of specific CAM software and circle-segment tools have made it possible to not only get to vertical and steep areas with tangent plane machining, but also on to any flat or shallow areas.

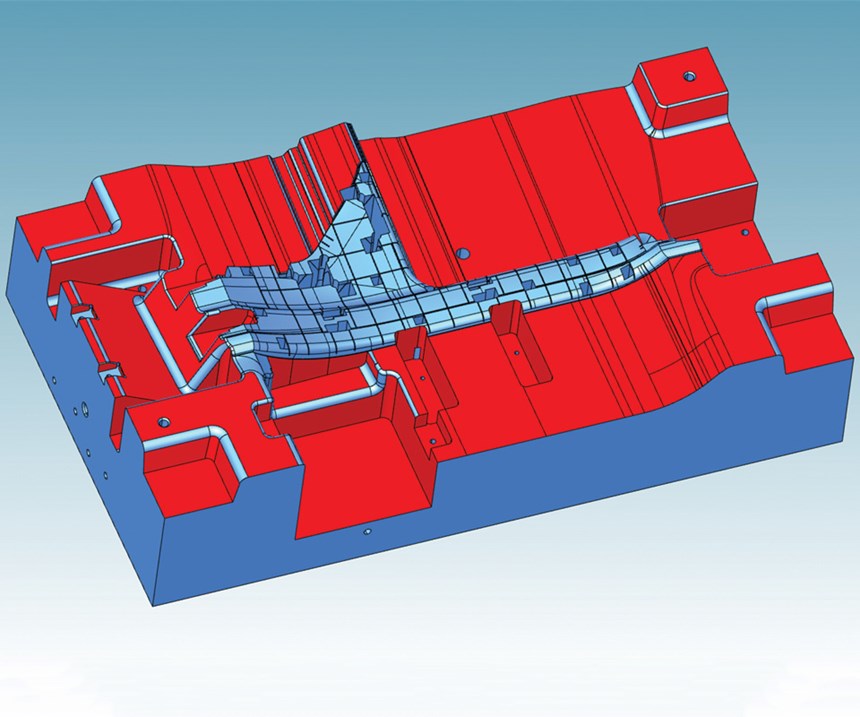

Figure 1 shows a large fascia mold on which the highlighted surfaces were machined using tangent plane machining. The greatest benefit was achieved in areas that cannot easily be machined by side milling with an end mill, since these pockets are quite deep. Traditionally, these surfaces would have to be machined using a ball end mill with a tight stepover. The larger the ball end mill, the greater amount of material that would need to be removed in the corners. Circle-segment end mills can easily access these vertical corners as well as the floors of deeper pockets.

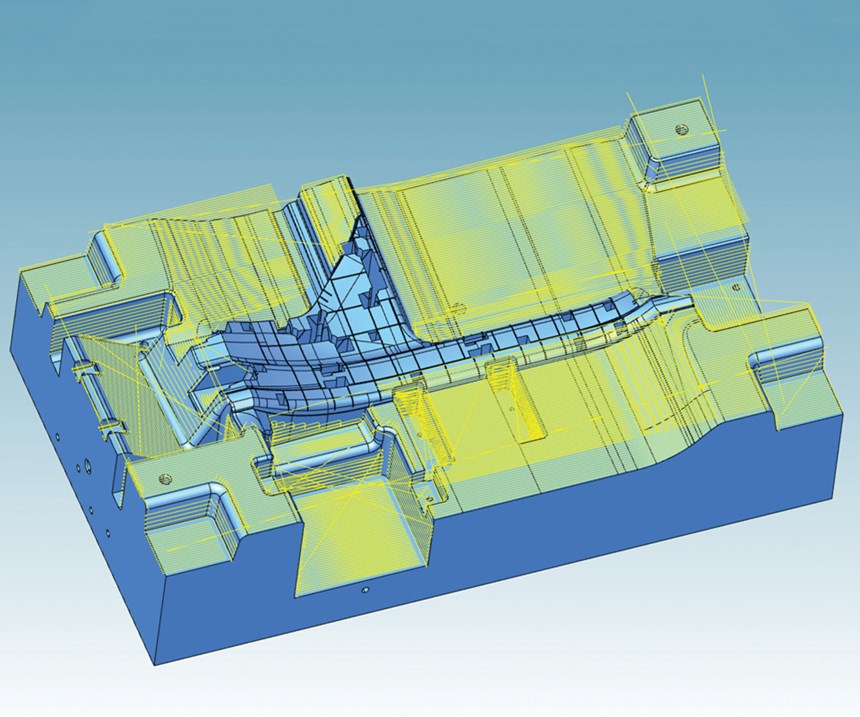

Complete tool paths for the large fascia mold in Figure 2, including the pocket bottoms and side walls, also were machined using a circle-segment end mill. It is important to note that a ballnose end mill took approximately 9 hours and 36 minutes to complete this machining process, whereas the circle-segment cutters took only about 1 hour and 10 minutes, an 88-percent reduction in machining cycle time.

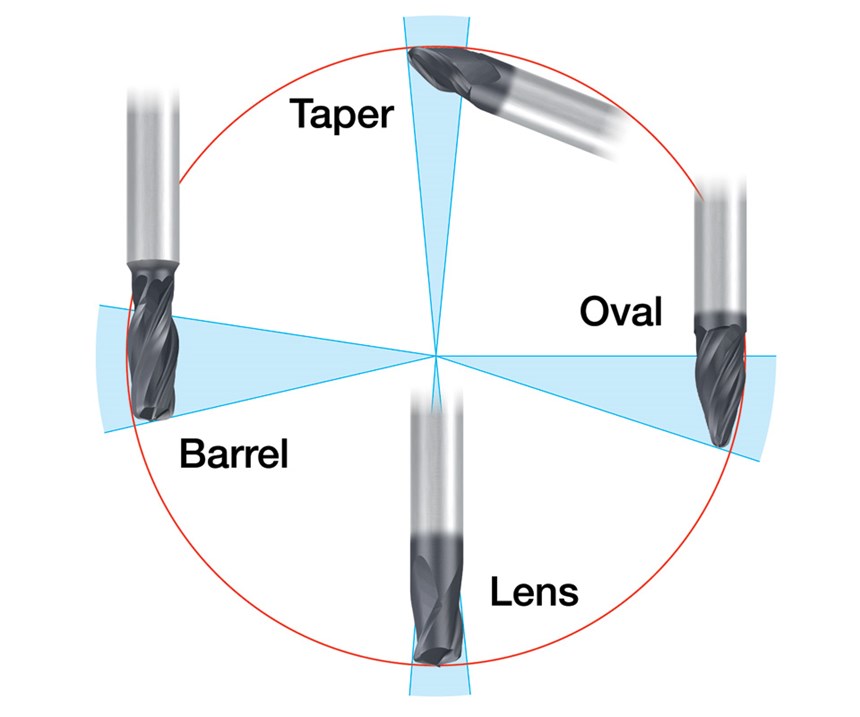

Circle-segment solid-carbide end mills are available in barrel shape, oval form, taper form or lens shape (see Figure 3), and are well-suited for moldmaking applications as well as for machining structural components, turbine blades, impellers and blisks. Oval- and taper-form end mills are suitable for curved shapes such as blades or straight-walled pockets, freely engaging more of the cutting edge. Barrel-design end mills provide highly effective flank milling to the sides of spiral grooves and similar applications, while lens-shape end mills excel in narrow channels or in lands on molds. Specific CAM system software is required to support the end mill geometry and compute the tool paths in order to achieve optimum performance levels.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Tips for Successful Hard Milling of Complex Molds

And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)