Innovative and, in some cases, unique lighting features on 2022 GMC Hummer EV pickups (above) and SUVs from General Motors Co. were enabled by both plastics design freedom and innovative tooling technologies. Photo Credit: General Motors Co.

Automotive lighting is one of the most exciting and technology-heavy areas of today’s passenger vehicles. No longer a one-size/one-shape-fits-all vehicles approach, lighting is being used as a market differentiator to signal that new vehicles are special, different and worthy of attention. Both forward and rear automotive lighting have become far more compact, complex, multifunctional, feature-rich, durable and energy efficient.

It’s no surprise that plastics — particularly injection-molded plastics — play such a pivotal role in these lighting innovations: first because of the high production volumes involved, second because of the high complexity of molded components, many of which must meet strict safety mandates, and third because of the high aesthetics needed to meet studio design requirements. And where there is innovation in injection-molded plastic parts, you can expect innovation in injection-molded plastic tooling. A great example of this can be found in forward lighting for the all-electric 2022 GMC Hummer EV sport utility vehicles (SUVs) and pickups from General Motors Co. (GM).

Not Your Father’s SUV

Today’s Hummer EV has evolved considerably from its light tactical vehicle roots — the high mobility multipurpose wheeled vehicle (HMMWV or, colloquially, Humvee) developed in 1983 and still produced by AM General for the U.S. military — and from the civilian version of that vehicle that AM General launched in 1992 and subsequently sold to GM in 1998. While the Hummer brand was discontinued between 2010 and 2021, it returned last year fully reimagined as an all-electric GMC sub-brand. As a result, the new Hummer EV is capable of the off-road hijinks made famous by its predecessors, and it’s a thoroughly tricked-out and luxuriously high-tech ride for the urban warrior.

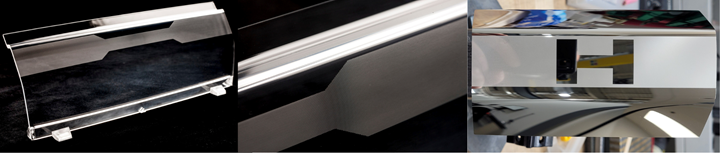

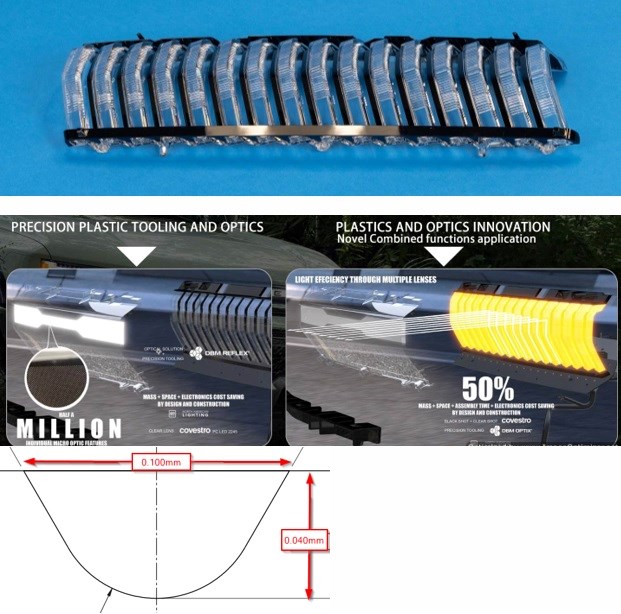

The Hummer EV’s signature front lightbar (top) was created with a series of innovative mold inserts (bottom). The B-sides of the clear inner lenses feature micro-optical details. When lit from below, that geometry creates a milky-white appearance on the otherwise relatively clear lens, spelling out the Hummer name or displaying an elongated “H.” When a turn signal is in use, the LED lighting the elongated H on that side shuts off. Behind the clear inner lens is a series of “piano key” light pipes (also created with mold inserts) that provide more lighting features. Photo Credit: General Motors Co. (top) and DBM Reflex (bottom)

Throughout the vehicle are multiple signature accent pieces, including elements of forward and rear lighting, that visually take the form of a stylized “H” borrowed from the Hummer name. Rear taillights feature thick injection-molded light blades in vertically elongated H shapes. The lit wraparound front lightbar features horizontally elongated Hs on the left and right animated turn signal segments, as well as the full Hummer name, spelled out in two additional segments that form the center of the lightbar.

New Levels of Innovation

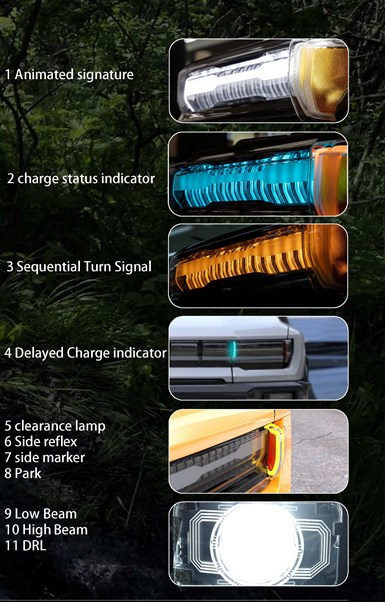

A closer look at the forward lighting system reveals even more innovation. The team at GM, Tier 1 North American Lighting Inc. (NAL), a Koito group company and its suppliers have developed a multifunctional system that combines 11 separate functions into the signature lightbar and headlights. In addition to its lit signature appearance, left- and right-animated turn signal modules in the lightbar also provide animated charge status and delayed charge status indicators — a first on any vehicle, electric or conventional. At the outer edge of each module are the side markers, side reflex (reflectors), clearance lamps and park lamps. Placement of the compact and low-mounted combination daylight running (DLR) lights and high- and low-beam headlamps are said to reduce glare for oncoming vehicles and vehicles driving ahead of the Hummer EV.

The Hummer EV forward lighting system combines 11 different functions — eight of them contained in the signature lightbar and with several features used for the first time on a passenger vehicle. Photo Credit: General Motors Co.

The lightbar assembly consists of four lamp modules, each comprised of four major components. At the bottom is the circuit board containing multiple LEDs and other electronics to power the system and produce light in various colors, plus specially designed collimators seated next to each LED that direct light up into the lenses above and prevent light absorption by the opaque black portions of each light pipe. The middle layer consists of clear “piano key” vertical light pipes (molded as a single large element with opaque black sidewalls between each clear light bar and an integral black bezel). Next up in the assembly is a clear inner lens with a signature appearance created by the micro-optical features on the B-side of the molding. Finally, a second clear outer lens cover closes and seals the system.

Additionally, a molded bracket blocks wiring and facilitates attachment. Total internal reflection (TIR) design in combination with wedge optics (optical features molded into the B-side of the light pipes) was used to control light distribution. The clear/black light pipe/bezel component is produced in polycarbonate via two-shot/two-color injection molding.

Design and process innovations were required to ensure a crisp, clear appearance with no light leakage between the clear bars (light pipes); light pipe sidewalls are molded in opaque black, as is the bezel, which required tight control of mold shut-offs to ensure accurate two-color molding. The light pipes allow two LEDs to use the same lightbar entrance space, meaning a single piano key lens can project light in two different colors at two different times depending on which lighting function is used. However, that also means that the positions of the LEDs and tiny entrances on the molded parts had to be precisely controlled.

Where there is innovation in injection-molded plastic parts, you can expect innovation in injection-molded plastic tooling.

An interesting aspect of the piano key light pipes is that they are not all positioned in the same plane. Instead, the orientation of the face of individual light pipes (including side view and rake angles plus thickness changes) was designed via NAL’s optical tools to optimize front surfaces, performance and uniform-lit appearance for the Hummer EV. Reportedly, there are 16 lit areas just for the turn function and each area has an amber and a blue LED to provide animated turn and charge functions, respectively.

NAL worked closely with GM and the toolmakers involved to refine GM’s initial concepts and ensure the manufacturability of the various lighting elements. In addition to providing all-optical photometry simulations, lit and unlit renderings and working with prototype suppliers to develop lit/unlit mockups, the company provided limited thermal, electrical and optical testing plus appearance evaluations on the prototypes.

The Hummer EV’s multifunctional signature lightbar systems consists of four lamp modules each consisting of four major layers. On the bottom is a circuit board with LEDs and collimators (not shown). In the middle (top and middle right images) is a single-piece cluster of clear “piano key” light pipes with black sidewalls and bezel. An additional bracket (not shown) is used to block wiring and provide attachments. Second from the top of the assembly is the signature clear inner lens with micro-optical features (scale shown on bottom). A final clear outer lens cover (not shown) closes out and seals the system. Photo Credit: SPE Automotive Div. (top), General Motors Co. (middle) and DBM Reflex (bottom)

Also, NAL conducted detailed mold filling and warpage studies for these parts. Warpage was a viable concern, as was the ability to accurately replicate micro cones and other molded optics during mold fill and pack. The company says that using process parameters developed by its production/molding engineers, CAE analysts worked on simulating the optimal process to mold the parts successfully. This included filling/warpage studies that considered variables such as the number and size of gates, the number and size of runners, the multiple thick-to-thin-to-thick transitions between each light pipe and controlling fill balance, cooling and ejection. Fill speed and pack pressures also had to be optimized to ensure plastic flowing across the textures and optical features did not introduce trip splay but rather imprinted each feature accurately in the molded parts.

Micro Milling

Given the complexity of the many unique elements in the forward lighting system, it’s no surprise that mold inserts were extensively used in the injection tooling. DBM Reflex produced 22 of those inserts, including the ones used to form piano key light pipes for all four modules of the signature lightbar, clearance/parking lights, side reflex, side markers and all inserts used to produce the micro-optical signature shapes on the clear signature inner lenses of the lightbar.

Those micro-optical features are essentially micron-scale cones (~0.10 millimeter wide and 0.04 millimeter tall) whose height is said to be half the thickness of a human hair and that protrude from the surface of the insert, creating microscopic indentations in the plastic lens in those locations.

Functionally, the cones scatter light falling on the face of the lens and slightly lower light intensity/reflection in locations where they are positioned. The difference between areas of the lens with and without the micro cones is what creates the milky white signature shape when the lightbar is lit. Although the micro cone technology has previously been used on taillamps, DBM reports this is the first time it’s been used on forward lighting elements.

Inserts with these micro cones were produced on DBM’s custom-built, six-axis diamond turning centers (the company has four of them) that are equipped with diamond (rather than carbide) cutters for the highest precision milling work. The machining centers, combined with custom software developed by DBM, produce micron-scale milling capable of exceptional surface finishes (Ra=3.0 nanometers) and optical precision (0.15 micron peak to valley). The company reports it can machine optical finishes on freeform surfaces without needing post-process polishing — a critical feature given that polishing would necessarily destroy the micron-scale cones. In addition to machining microstructural optical shapes on headlights and various optical shapes on forward and rear lighting, the company says it also cuts diffractive optics on this equipment.

While diamond is the hardest substance on earth, it’s challenging to use it to cut ferrous metals since iron and carbon fight over electrons and iron always wins, meaning diamond cutters don’t last long when cutting steel inserts. Hence, DBM produces a master unit in a non-ferrous material, then uses that to create an electroform nickel insert with a chromed finish.

Micro-optical cones molded into the B-side of the lens (left) scatter light hitting the molded surface and selectively create a signature appearance like the elongated H (left and middle inset). Micro milling using diamond cutters was required to produce the 12-nanometer geometry on the inserts (right) that created this effect. Photo Credit: DBM Reflex

Interestingly, while DBM originally developed the concept for the micro cones, a lot of work was required between GM, NAL and DBM to balance the visibility of the signature elements in unlit and lit situations and make the technology commercially viable.

“With our initial mockups, we machined a structural cone density of 16 cones/square millimeter, which yielded micro-optical features that were visible when lit but became almost invisible when the LED light source was turned off,” explains Maxime Charette, DBM Reflex project manager. “However, to enhance the contrast between areas of the lens with and without the micro cones and balance that with the homogeneous lighting effect GM desired, our joint team worked closely to find the right balance, which ended up being a density of approximately 70 cones/square millimeter.”

Sticking Point

Windsor Mold Group (recently acquired by ABC Technologies Holdings Inc.) and Active Industrial Solutions (AIS) Technologies Group Inc. (acquired by SyBridge Technologies Inc. in 2021) built the tools that housed the various inserts.

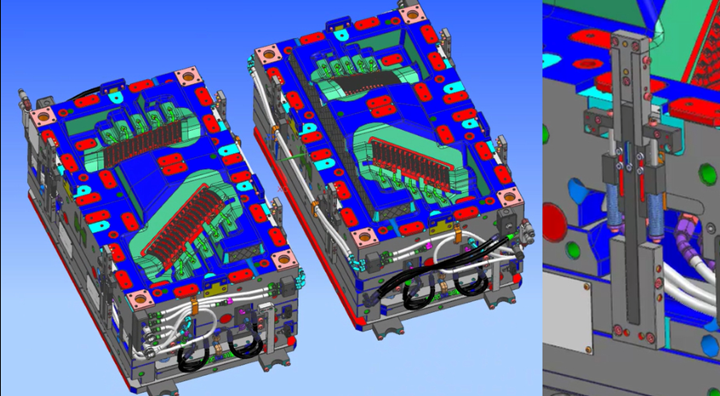

The complex mold that produced the left- and right-side animated piano key light pipes for the Hummer EV animated turn signals was produced by the Mobility Div. of SyBridge Technologies Inc. Owing to a number of features on the parts being molded, it was necessary to use a modified latch-lock system (right inset) to ensure smooth opening of the tool during part ejection. Photo Credit: SyBridge Technologies Inc.

The 1+1 tool that produced left- and right-side piano key light pipe clusters for the animated turn signal modules were interesting owing to its size and complexity. The mold size was 56 × 22 × 36 inches/142 × 56 × 91 centimeters, weighed 11,000 pounds/4.91 tonnes and was sized for a vertical press with 1,300 tons/tonnes of clamping pressure. It was equipped with five hot runners and five edge gates to shoot the clear polycarbonate light pipes and the black polycarbonate bezel and light pipe sidewalls.

NAL and SyBridge worked closely to ensure tight control of shut-offs between clear and black features. Both core and cavity were machined from MLQ P20 from Finkl Steel. Additionally, NAL reports that the tools to mold the piano key light pipe used a large retractor across the bottom of each part and a big insert to produce optics on all the light pipes.

“One of the true challenges of this project was that timing was very compressed — just 18 months — so it required the involvement of cross-functional teams working in multiple regions, including the U.S., Japan and India, to provide simultaneous engineering and feedback for these complicated parts and to complete development in time.”

Notably, after the initial mold trial, the SyBridge team determined that the standard latch-lock system that had been installed (two latch locks on each side) needed to be modified as the tool was proving difficult to open during demolding. Latch locks permit precise control and movement of multiple parting planes during opening and closing of an injection tool.

“On this particular tool, we had lots of texturing on the periphery of the parts to keep them positively located on the core during fill and pack,” explains Ed Ergun, SyBridge corporate sales director. Additionally, these large parts had thick sections and tall walls that created a friction bond. Still another challenge was that owing to the high amount of optical surface on each part, and the fact that headlamps must meet safety mandates, it was critical to produce optical surfaces precisely and prevent distortion of the still-warm parts during ejection.

After the initial mold trial, the SyBridge team went back to work and developed a custom-modified latch-lock system sized for this tool and designed for the travel needed. Once in place, the modified system permitted opening of the various plates and prevented the ejection system from moving forward during mold open. “Adding the modified latch locks after the first mold trial solved the problem and enabled parts to be produced as designed in a production environment,” adds Ergun.

“One of the true challenges of this project was that timing was very compressed — just 18 months — so it required the involvement of cross-functional teams working in multiple regions, including the U.S., Japan and India, to provide simultaneous engineering and feedback for these complicated parts and to complete development in time,” explains Roxana Hijaouy, NAL design engineering manager.

“Plastics allowed for the signature inner lens to achieve an aggressive shape to realize the design studio’s vision of signature lighting that appears to ‘float’ inside the headlamp,” explains Jeffrey Ulrich, GM lead design release engineer – Exterior Lighting, Hummer EV. “The light was able to be redirected through the geometry of the inner lens to illuminate the signature on the vertical face. In addition, multi-shot/multicolor plastic injection molding enabled the Hummer EV turn signal lens to achieve the appearance of 16 individual lit segments with a single part. This lens is used for the sequential turn signal animation and provides the segmentation needed for the first EV charge status indicator integrated into a turn signal.”

Related Content

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreHow to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreRead Next

Hybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MoreAdvances in P20 Steel Potentially Eliminates Need for Stress Relieving After Rough Cutting

Omega Tool Corp. compares conventional, new P20 grades side by side in production fascia tools, finds no downside.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read More

.jpg;width=70;height=70;mode=crop)