Detecting, Repairing and Preventing Water Leaks--Part 2 of 3

Probable causes and repair methods with an eye on preventative measures.

Last month we discussed how to detect water leaks at the press and at the bench. Now we will begin to examine probable causes and repair methods with an eye on preventative measures that should be considered to prevent the leak from reoccurring altogether or better manage it through specific corrective action techniques at predetermined cycle counts.

Every corrective action must be looked at from two perspectives. First, what is the immediate action required to repair the leak and get the mold back into production and then understanding/identifying the root cause of the leak, so that it may be eliminated or controlled (preventative) through scheduled downtime events.

Fortunately for most injection molds, seals are not required to withstand extremely high water pressures (usually only 45-60 psi) or frictional/abrasive heat/wear from sustained high rpms. The seals are simple, and for the most part easy to get to, although I have worked on molds where o-rings were tucked into a groove inside a .125 dia bore. They could only be removed/replaced under a microscope.

The list of probable causes for o-ring failure is not nearly as difficult to control as the mindset required of repair technicians to focus on the mundane details that make or break a production run.

Two Types of Seals

Static (stationary tooling) seals are o-rings placed between tooling or fittings that do not move—such as cores trapped and sealed between plates, or cavities housed in a bore with external o-rings that seal against the I.D or walls of the bore.

Dynamic (rotating or reciprocating) seals are those where tooling is in motion against an o-ring or quad seal—such as unscrewing cores and cavities. Also in this class are hot runner molds with pneumatic or hydraulic valve gate components. The valve pin pistons contain o-rings that undergo higher temperatures (600 deg with some resins) and higher pressures (500 psi for hydraulic systems) than standard water pressure.

The probable cause list for static and dynamic o-ring failure in molds is as follows:

O-ring failure

• Compression set, thermal and chemical degradation, incorrect hardness or elastomer

Incorrect mold assembly

• Wrong size, twisted, pinched, cut, missing or inadequate lubrication

Tooling and plate condition, design

• Cracked tooling, worn/pitted glands, incorrect stack dimensions, gland depth or surface finish, inadequate bolt patterns

The Science of the Seal

After an in-depth Web search and listening to numerous manufacturing reps speak in molecular detail, it is apparent that o-ring design/sealing is more complex than just a piece of rubber being squeezed between some tooling.

The crash of the shuttle Challenger was frequently used to illustrate how even the simplest of mechanical functions can bring down a goliath of engineering wizardry, if not properly design and maintained. And so it goes in plastics manufacturing. Although not life threatening (maybe), thousands of critical production runs are halted every day by the failure of this simple seal to do its job.

Typical o-rings are molded from a half dozen different elastomers available in hundreds of different compounds each with some type of application advantage. The majority of o-rings used in plastic injection molds are made of Buna-N (Niltrile) and Fluorocarbon (Viton). In some cases silicone and LSR are utilized in applications requiring exceptionally pliable or soft o-rings of low durometers (50 or less Shore “A” Hardness). These type o-rings work well in molds with pitted glands and plates. Most typical o-rings in mold applications measure 70–90 durometer.

If you require more scientific or specific information concerning elastomer and compound capabilities for heat, chemical or pressure requirements, there are several online resources who publish their own troubleshooting and selection guides for tooling engineers or mold designers. For our purposes, we will stick to dealing with typical o-ring issues as seen in most mold repair shops.

Common O-ring Failures

Compression set is a phenomenon that causes most water leaks (not related to installation) in molds today. Simply put, this means that an o-ring has resided in a compressed state in the mold for so long that it has lost its ability to apply adequate force in the gland and overcome the applied water, air or hydraulic pressure.

This usually occurs with tooling that is difficult or time consuming to remove such as A and B side cavities or tooling requiring a complete mold disassembly to reach. In many shops, if there is no reason to remove this tooling (like a compulsory PM program), then it is overlooked in lieu of a speedy repair to get caught up with the red-tag mold count or to get the mold back into production.

Thermal degradation will accelerate this compressive set behavior such as when a hot runner system is fired up without turning on the water to the cavities. The compressed o-ring is then baked in this set condition—basically being “remolded” in the bore and reducing its ability to seal.

This is another in a long list of reasons why it is critical to follow mold start-up procedures and change o-rings after a predetermined amount of time, based on visual inspection of the o-rings at predetermined intervals to establish a cycle baseline.

Chemical degradation normally only occurs during mold cleaning operations when tooling is cleaned with the o-rings intact or in the bores. Some elastomers such as Nitrile and silicone are susceptible to swelling and softening if exposed to certain cleaning solutions such as acetone or MEK (methylethylketone). Caustic cleaners such as sodium hydroxide, a popular solution used in ultrasonic cleaning tanks will have the same effect on Fluorocarbons, so it is important to stay within the o-ring manufacturer’s recommendation of cleaning solution percentage.

Wrong Size O-ring

Another common occurrence in fast-paced repair shops is to grab any o-ring that looks like it might stretch or compress enough to work, regardless of the correct size. This usually happens when o-rings are removed from tooling before first checking to see if new o-rings are available from the storeroom.

If the old o-rings are damaged during removal (and they usually are) and you don’t have enough of the correct size in stock, then an alternate size will be required to get the mold back into production. The problem here is the substituted o-ring might appear to work on the bench, but will begin to leach water slowly under the cycling of clamp and injection pressures. And if the next repair tech doesn’t know that the new o-ring is not the correct size, troubleshooting this slow leak will be time-consuming and frustrating.

To avoid this problem, every maintenance manual (electronic or hardcopy) should contain the specific sizes of critical o-rings in a mold. But be advised that attempting to include all o-ring info in every manual of every mold can be overwhelming. Make a habit to record the o-ring sizes of the molds that get repaired for leaks. Before you know it, you will have collected accurate data for the molds that need it.

Short “Cuts”

Many repair technicians (and production supervisors) do not like to disturb o-rings until they begin to leak, the idea being “why look for trouble” especially on a mold where the plates’ water channels intersect cavity bores. Older (and newer “low priced”) molds are designed without stepped bore I.Ds, which creates a razor-sharp edge at this intersection.

The more popular, quick fix is to change out the o-rings only after they begin to leak, and then only changing the one that is leaking, forgoing the others until another day. This is firefighting at its worst. And furthermore, while waiting for the rest of the o-rings to eventually leak, the residual contamination (iron/rust) that collects around the o-rings will speed the eroding/pitting of the bore walls. Now you have real problems.

The correct repair is to hand-work these sharp edges (figure on five to 10 minutes per cavity using a Dremel, medium stone and finishing with a medium Cratex wheel) to a point at which they no longer will bite the o-ring as it passes over. This is the more time-consuming procedure, but once it’s done, it’s done, and all the o-rings can be changed more frequently, much quicker and safer with no more worries about random leaks shutting you down. Keeping the o-rings fresh and the bores clean will reduce short- and long-term damage.

Editor’s Note: You can read the next part in the series by clicking here.

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreWhat Is Scientific Maintenance? Part 1

How to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

Part Three of a Three-Part Series Detecting, Repairing and Preventing Water Leaks

Clear cut methods that prove effective on troublesome installations.

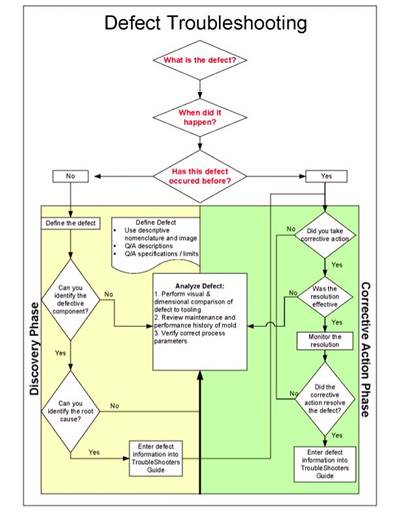

Read MoreAcross the Bench: Troubleshooting Defects: Part I

Using analytical skills based on historical mold performance and maintenance requirements, combined with mold and part defect data determines probable causes and corrective actions.

Read More