ARBURG, Inc.

644 West Street

Rocky Hill, CT 06067 US

860-667-6500

usa@arburg.com

arburg.us

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

ARBURG, Inc. Supplies the Following Products

- Additive Manufacturing Machines for polymer parts

- Additive Manufacturing Machines—Material Extrusion

Editorial, News, and Products

-

Combining Innovation and Artistry to Build Complex, Precision, Multi-Cavity Molds

This Florida mold builder is about high-performance, high-precision moldmaking by blending craftsmanship with technology.

-

Openness to New Manufacturing Techniques Gives Mayer Tool & Engineering a Competitive Edge

This Michigan mold builder adapts, problem solves, brainstorms and collaborates to exceed customer expectations.

-

Technology and Sourcing Guide 2023: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment. Access this exclusive, online-only content, including a suppliers list, AM products and more.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

Technology Roundup: The K Show Experience

Catch a glimpse into technologies for plastics, rubber, injection molding, hot runners, sustainability and more being showcased at this year’s K 2022.

-

Mold Monitoring System Provides Real-Time Mold Performance Monitoring

Arburg showcases a range of machines highlighting digitalized manufacturing including the Hack Moldlife Sense system, used to detect and notify operators about errors and irregularities in the mold.

-

Multicomponent Mold Combines Capping, Unscrewing Functions for Pharma Closure

Braunform says its patented RotaricE² mold, which will mold Luer lock pharmaceutical closures in Arburg’s K 2022 booth, enables the use of one tool and one machine, versus two, while eliminating post-mold assembly.

-

Arburg and Hasco Partnership Provides Turnkey Solutions

Since the beginning, Arburg has used Hasco as its supplier of standard mold components.

-

Midwestern Advanced Manufacturing Design Technology Program Presents Unlimited Career Possibilities

Advanced Manufacturing Design Technology program at Central Community College offers new facility expansion and 100 years of instructor experience to mentor students from drafting, manual machines and CNC to part, mold and die design and advanced machining.

-

New Arburg Managing Director Heads up France-Based Subsidiary

Heading up the subsidiary since November 2020, Pascal Laborde continues to develop Arburg’s business in France, with a focus on the company’s Allrounder technologies and AM.

-

Technology Roundup: You'll Only See It Here!

MMT presents a compilation of digital-only new/proven product content. Cutting tools, machining, AM, software and inspection/measurement categories are showcased in this latest roundup.

-

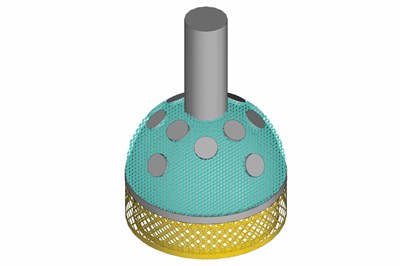

Arburg Filter Production Rounds Off Facemask Project

In collaboration with several companies, Arburg applied its injection molding know-how to develop a multifunctional face mask made from LSR and PP in 41 days.

-

Arburg Recruits 2,000th Apprentice

The company’s apprenticeship program, running for more than 70 years, has reached a major milestone with its most recent recruit, engineering technician Michael Gross.

-

Arburg Manufactures High-Tech Masks

Arburg has launched a face mask project to combat the spread of the coronavirus.

-

Arburg Announces New Managing Director, Technology and Engineering

At the start of the year, Guido Frohnhaus took over as managing director, technology and engineering at Arburg GmbH + Co KG in Lossburg.

-

Plastikos, Inc. Invests in Micro Molding Equipment

Plastikos, Inc. has further diversified their product portfolio with the purchase of two Arburg micro molding machines.

-

Noteworthy News: Develop Your Skills

These recent news releases present a wide range of options for industry education, from courses both in classroom settings or online to earning credentials to networking events.

-

Extensive CAD/CAM Functionality Helps Complete Medical Mold Build in 6 Weeks

The industry has been talking a lot about automotive lately, so I thought I’d switch things up a bit and share the success of a medical device mold project attributed mainly to the right CAD/CAM with built-in mold component supplier catalogs.

-

Machine Technology Covers Wide Range of Processes

At K 2019, Arburg, Inc. will display a number of new machines, processes, and digital products and services.

-

85 Trainees and Students Begin Apprenticeship at Arburg

A total of 85 new trainees and students from the Baden-Württemberg Cooperative State University began their apprenticeship at Arburg on 2 September 2019.

-

Noteworthy News: Winning Streak

Everyone loves a success story, so take a moment to appreciate and applaud a few from the moldmaking community with the following news releases.

-

Arburg Awards Two TUM Graduates

The 2019 Arburg Awards were presented to Dr.-Ing. Hannes Löwe and Maria Gabriele Bauer.

-

Arburg Inc. Wins People's Choice Award at Rapid + TCT 2019

From May 21-23 2019, more than 400 exhibitors and around 7,000 trade visitors attended the Rapid + TCT, the leading trade fair for additive manufacturing in the U.S. On the last day, Arburg was honored with the People’s Choice Award.

-

Highly-Automated Tool Shop Achieves Efficient, Precise Medical Device Manufacturing

When a basketball player needs a knee replacement, standard implants simply won’t do. With a total of 18 different additive manufacturing systems, the Aesculap division of medical company B. Braun is the place to go to have custom implants printed to size. However, the highly-automated tool and mold shop has much more to offer when it comes to producing injection molds, complex progressive dies as well as prototypes and fixtures for series production.

-

Coupler Lends Easy, Reliable Solution to Quick Mold Change

A coupler helps provide a faster, more reliable way to tie positive return ejection into a mold.

-

Arburg Welcomes New Apprentices

A total of 67 new students recently began their apprenticeship at Arburg.

-

Automation Increases Molding Options for Zahoransky USA Customers

MMT interviews Zahoransky USA Inc. to learn more about the company’s expertise in integrating automation with the precision injection molds that it builds.

-

2018 Technology Review and Sourcing Guide: Additive Manufacturing

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including additive manufacturing.

-

Freeformer System Offers Flexibility in Prototyping

With so much happening in a busy show year between NPE2018 and Amerimold 2018, MoldMaking Technology is revisiting some of the technology that was on display. In case you missed it: Arburg says that its Freeformer customers can qualify their own materials using the APF process and optimize process parameters to the application at hand.

-

Small Family Mold Shop Turned Small Family Business

By aiming to improve at least one thing every day, Artisan Model Mold Owner Jonathan Stanwick turned the small family shop into a small family business.

-

NPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

-

Engage the Next Generation – Sponsor the Plastics Race

Sponsor The Plastics Race. Engage the next generation workforce by promoting our industry and your company. Participate in The Race and build relationships!

-

Technology Tuesday: Preparing for NPE with Plastics Review

This slideshow has you covered in plastics review with discussion on common plastics problems like sticking and warping. It includes pieces on software analysis for plastic parts, and it even includes a piece on making the most out of used plastic.

-

Moldmaker Investments in 2017

Mold builders share their best 2017 technology and people investments and the resulting return on investment.

-

Technology Tuesday: Products Featured at Fakuma 2017

More than 1700 exhibitors will showcase products at the 25th anniversary of Fakuma, an international trade show for industrial plastics processing. This slideshow highlights some of the products that will be on display.

-

SLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

-

Seeing the Industry with a New Perspective

Last week I attended Plastec West in Anaheim, California (what a nice break from frigid temps in Chicago!). It was my first trade show as senior editor of MoldMaking Technology versus attending as a public relations manager for plastics industry suppliers, and I enjoyed seeing everything with a new perspective.

-

Additive System Produces Functional Plastic Parts

Arburg’s freefomer system builds plastic components from the ground up with the same, pelletized material as a plastic injection press.

.jpg;maxWidth=300;quality=90)