PFAFF Werkzeug- und Formenbau GmbH & Co. KG offers molds, notching, automation and production equipment for vehicle body sealing systems headquartered in Germany with locations worldwide, including a strong presence in North America thanks to its North Carolina facility. Photo Credit, all images: PFAFF Molds

Who is PFAFF?

Troy DeVlieger, president, PFAFF Molds: Stefan Pfaff started the PFAFF Group in 1957 in southern Germany. Stefan was later succeeded by his son, Armin Pfaff. The current owner is Moritz Hummel. It has been a family business with a single owner ever since. The business grew from a “one-man show” solving problems for a local supplier in the industry to a global leader by adhering to the same founding principles to solve problems for our customers and regard our employees highly. Today, the expertise of the PFAFF team is found in almost every automobile brand.

PFAFF Werkzeug- und Formenbau GmbH & Co. KG supplies molds, notching, automation and production equipment for vehicle body sealing systems headquartered in Röthenbach (the Allgäu region of Germany) with locations worldwide, including our North Carolina facility. Molds and equipment for the auto sealing industry are all we do. We’ve been asked many times to branch out into other areas, but we are a specialist in this niche market and want to continue as a global leader. We collaborate with our customers to develop custom solutions for each project, from prototype molds to volume-production molds with simple designs to highly complex automated systems.

PFAFF has been operating in the American markets for customers in the U.S., Canada, Mexico and South America since the 1990s. I started with PFAFF a little over 20 years ago. The office was over by the Charlotte airport, and we outgrew that facility over the years and decided to build a new facility in SW Charlotte. Then in 2008, we broke ground on the new building and have continued to grow ever since. This central location means we can serve the entire North American market effectively. Today, we have about 30 employees in our Charlotte facility, with 60% of the workforce under 40.

This niche market is about managing the workflow accurately, manufacturing efficiently and mentoring our employees to prepare everyone mentally for the ups and downs of a chaotic workflow.

I came to PFAFF because I like a challenge and our products are completely different than what I was used to. It is also a family-owned and operated company that places a very high value on its employees. It was an opportunity to learn something new, but it takes a unique person to stay in this industry because it’s fast-paced and highly stressful. You have peaks and valleys because they don't release programs for new vehicles equally every month throughout the year.

We have one or two times a year when things peak and a few months when things trickle in due to program delays. This niche market is about managing the workflow accurately, manufacturing efficiently and mentoring our employees to prepare everyone mentally for the ups and downs of a chaotic workflow.

Molds for vehicle sealing systems can be intricate. The final parts are flexible and pliable assemblies that require a vertical molding press to enable easier loading and unloading of the product during the molding process.

What is the main difference between a rubber and a plastic mold?

DeVlieger: For a TPE/TPV mold, you melt plastic at 400oF to 500oF and inject the melted plastic into a cooled mold. With rubber, it’s the opposite. The rubber is only warmed, not molten, and becomes less viscous under high pressure and heat. It enters a mold that is about 420oF, and once the material enters under pressure, it vulcanizes and cures over time. The injection pressure must be high because the material is viscous when you push it into the mold. The cool thing is that we can do both.

What is the most significant challenge you are experiencing?

DeVlieger: The lack of a skilled workforce pipeline, not just for us, but for our customers as well. This challenge led us to partner with an existing apprenticeship consortium (Apprenticeship 2000) and eventually integrate automation into our solutions for our customers to decrease their strain on the talent pipeline. Our customers need to do more with less, which is all about automation and bringing that semi- or full-automation program to scale, so our customers can produce quality parts efficiently and cost-effectively in a global market.

PFAFF Molds has accumulated decades of experience and knowledge in its niche industry, which requires a lot of upfront engineering.

The nature of our product requires a lot of upfront engineering and experience, and it doesn’t lend itself to automation easily. Most moldmaking and molding in plastics is horizontal. Our process is vertical and typically requires human operators to load the profiles, clips, inserts, glass or whatever is designed due to the intricate loading process. Molds for window sealing systems on a vehicle are intricate and typically cannot just be stuck in a horizontal press that cycles automatically every 20 seconds and drops a part onto a conveyor. Instead, our typical process is vertical and more complex. Until now, it required a human’s skill and dexterity to load all those components properly and unload the finished product without damaging it. But that’s changing, as mentioned, with modern technology and our automation concepts.

For example, we recently did a program for a customer where we developed a work cell that reduced the workers required from 54 people to 27 people. That's a reduction of 50%, and a huge benefit to our customers when they can’t find workers. It’s fully automated once the profile is inserted and is most likely one of the most profitable cells in the facility for them. Currently, we are working on a newer but different version of this system as we speak. We think these platforms have the potential to revolutionize the sealing industry. We’re excited to share and implement these new innovative ideas and concepts to resolve customer issues. We’ve accrued decades of experience and know-how in the industry, and we're putting it to good use.

A mold design for vertical molding is very different from an open-and-close system on a horizontal press.

Our toolroom houses a variety of molding machines. We have sponge molding, thermal plastic and hybrid presses that mold thermoplastic and rubber. Designing a mold for vertical molding differs entirely from an open-and-close system on a horizontal molding machine. The tolerances can be three times tighter on a rubber mold than a plastic mold. Everything is hand-fit and hand-scraped by a moldmaker because the flash tolerances are about 0.02 millimeter. After all, the injection forces can be anywhere from 3,000 psi up to about 15,000 psi maximum. The required injection and clamping force are much higher with rubber molds than with thermoplastic molds.

How do you view the opportunity in the electric vehicle (EV) market for PFAFF?

DeVlieger: We are excited about electric vehicles (EVs) becoming more prevalent because when you're inside an EV, what will you not hear? An engine and transmission. That drowns out many noises you would typically hear for any sub-par sealing systems. So, think about how much tighter and quieter the cabin must be when driving with all the wind and road noise. This demands a higher-performing seal system with a higher degree of engineering throughout the whole process, and that is our specialty.

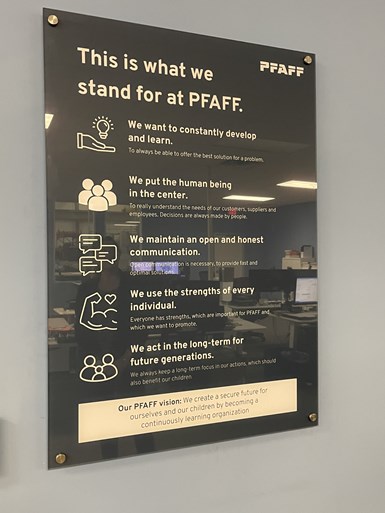

Describe the PFAFF culture.

DeVlieger: It is a business with strong family values that are core to PFAFF’s identity and success. Most recently, this culture helped get us through the pandemic. Everyone here is a team player.

The foundation of PFAFF’s culture is strong family values that foster a team-centric, learning environment.

We’ve always worked closely on projects together between our various international facilities by leveraging the strength of each facility, so we were used to communicating well with each other using digital platforms. For example, when COVID hit, it was a smooth transition to working digitally and remotely where possible, locally and internationally. We kept the business going while being able to keep almost everyone working and safe through the process.

We also care deeply about the professional and personal development of our employees. We hire for character and teach talent. If we hire the right person willing to learn, we can teach them about anything.

Let’s talk about training.

DeVlieger: We are a learning organization. We can buy more computers, software and equipment, but our people are integral to this process. You cannot teach our specialty in six months, a year or even three years. Because it’s such a niche product and there’s so much to learn, training and retention are critical.

We’re so passionate about training that we are developing our web-based training platform to train our employees and eventually to help train our customers’ employees.

The toolroom has DMG MORI machine tools, including five-axis milling machines with pallet changers.

PFAFF has a unique training program that offers dual work and study in the company and at a local college in Charlotte. The program lasts four years, is 8,000 hours and leads to a journeyman certificate and an associate degree in mechatronics from the local college, Central Piedmont Community College (CPCC). An apprentice is paid during on-the-job training throughout the program, and PFAFF even assumes the college costs while the students are in the classroom.

The dual education program, which combines theoretical knowledge and practical experience, provides the best possible preparation for the contemporary working world, plus excellent prospects of being taken on at the end of it. We guarantee a job at the company if they graduate from the program.

Over the four years, apprentices acquire know-how in pneumatics, hydraulics, control engineering, machining, mechatronics, CNC machines (programming and control), electronics and design. These subjects help apprentices discover their unique skills and interests, which help them decide on the appropriate career path, such as a CNC machinist, moldmaker, service technician or eventually a programmer or designer.

It’s all about the talent pipeline.

We’re partners of an award-winning program, Apprenticeship 2000, developed in 1995 to create a skilled workforce locally in the Charlotte, North Carolina, area. We’ve been a part of that now for 14 years. It’s all about the talent pipeline.

PFAFF exposes the next generation to experienced mold builders, machinists, engineers and managers who offer apprenticing for skills both at work and outside of work.

Partner companies provide jobs by training apprentices for skilled trades and, in return, gain the skilled workforce needed to operate their high-tech businesses. Apprenticeship 2000 is four-year technical training program designed to develop people for highly skilled technical trades such as machinists, tool and die makers, mechatronics technicians, moldmakers and electricians. The program works with highly motivated juniors and seniors from surrounding high schools.

After they finish the program here in four years, they can enter the workforce. If they want to stay, they have a guaranteed job at market price for their experience — no strings attached with the sponsoring company. We do that because if we do our job right from a cultural standpoint, teaching the technical aspects correctly, why would a person want to leave? If someone wants to leave, we don’t want to bind them by contract and have an unhappy employee. That creates more problems.

What schools are you working with to promote moldmaking and PFAFF?

DeVlieger: We work with all local high schools. However, the closest schools to us are Palisades and Olympic high schools. At the school level, people like Mike Realon have been an integral part of the success here locally for apprenticeships. Both schools are promoting alternative college and STEM-related options because the cost (debt) ratio to ROI (job placement – earnings) for many college students isn't working out. You hear about it on the news frequently, in politics and from friends that these students are very concerned about the cost of furthering their education to get a good job and earn a good wage. Plus, many employers are looking for more work experience and soft skills rather than just a degree.

The future is wide open for them if they can see it!

We invite these high school students to PFAFF through an orientation and vetting process. Aside from aptitude testing, one of the first things the students do is work on a vice with a piece of steel and a file, and after about 15 minutes I can tell you which ones will likely make the cut to the next level just by looking at the body language, how focused and engaged they are. Last year, we had about 35 or 40 students apply for an apprenticeship.

The future is wide open for them if they can see it! The next generation is conditioned to receive immediate information and gratification. So, when you tell a student that they will blossom in their career in 10 to 15 years with a lot of hard work, they don’t like to hear that either. It is a different concept for them, but it’s the truth. They’re not looking that far down the road.

However, for some, they are seeing the opportunities and earning potential. We try to help them see the big picture. For example, they won’t have any college debt to pay off. In the meantime, they are making a very good wage, in very high demand, and can work anywhere in the country and find a good job that pays well.

What do you think is special about PFAFF's training philosophy?

DeVlieger: Aside from the apprenticeship, the whole process is sharing knowledge and experience through mentorship. It is the key to their personal and professional development. Our team is unselfish and wants the next generation to succeed and are willing to share their years of gained knowledge. A seasoned mentor by an apprentice’s side is the key to building their confidence, enabling complex conversations, instilling aspirations and setting goals. That helps build interpersonal communication, team building and other soft skills that most don't have when they arrive.

The learning process is based on sharing knowledge and experience through mentorship.

PFAFF offers exposure to experienced mold builders, machinists, engineers and managers like many shops, but here you are not just apprenticing for skills at work, but for skills outside of work also. A lot of life experience trickles down to the younger generation here that an average 18-year-old out of high school will not receive. We have fourth-year apprentices buying new cars, moving into houses, having mortgages, getting married, investing, etc. They often inquire about these experiences because they are comfortable discussing them with their mentors. They are also getting life lessons on the job. For example, why it is important to be on time and do your job well and the impact on others when you don’t? The lunch or coffee breaks can be quite entertaining and educational around here. Manufacturing apprenticeships can offer extra benefits, but such additional benefits are hard to sell as part of the program because how do you sell life experience on the job as a benefit?

The best thing we can do is bring them in and help grow them into confident young adults by teaching them job and life skills. I’ve seen it. They come in one way, mature, gain self-confidence, become financially independent and change their outlook on life because of the opportunity provided. So, business is one thing, but bringing these young kids in here and watching them develop and succeed in work and life changes them. It gives them a vision, hope and the confidence to see what they are capable of and to become self-reliant. It is priceless. It’s the most rewarding part of my job.

I believe one of them will have my job one day; they just don’t know it yet.

Share some of the software and machine technology you employ.

DeVlieger: Our design engineers work with Catia V5, and our CNC programmers use Cimatron and Vericut. The shop floor houses DMG MORI machining centers and includes five-axis milling machines with pallet changers.

We also sample our molds and produce the first parts in our in-house tryout center on our LWB injection presses. We produce first off, low-volume production parts if required. The key to successful sampling is our employees’ knowledge-sharing experience and attention to detail.

What is your relationship with Haidlmair?

DeVlieger: We are also currently partnering with Haidlmair to support them in establishing their service and support center in the North American market. We are in the same industry and building, but the product lines differ. They build large molds for food, beverage, storage, pallet and crate systems.

Related Content

International Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Read MoreNorth Carolina Mold Builder Works With Purpose and Partnership

Adapting and innovating amidst a change in ownership, doubling sales and maintaining the workforce reflects team resilience and expertise.

Read MoreOpenness to New Manufacturing Techniques Gives Mayer Tool & Engineering a Competitive Edge

This Michigan mold builder adapts, problem solves, brainstorms and collaborates to exceed customer expectations.

Read MoreFather/Daughter Team Takes Mold Business into the Future

Innovation, personalized service and a team’s collective mold manufacturing experience earn customer loyalty for 56 years and set the business up for future success.

Read MoreRead Next

Part 1-Finding, Training and Retaining Employees

Before beginning your search, sit with your management team and list the non-machining skills, accomplishments and attributes you know someone must have to be successful at your company.

Read MorePutting Recycled Plastics to Work

Haidlmair discovered that if recycling is done correctly, the difference between virgin and recycled plastic material is minimal.

Read MoreA Proven Model for Apprenticeship

Steve Rotman, president of Ameritech Die and Mold, sheds light on his experience as one of the founding members of an apprenticeship program that has been churning out skilled workers for his shop and others since the mid-1990s.

Read More