Operating on multiple shifts with 24-hour manufacturing capabilities, the experienced Mid-America Machining team offers a complete “Total Tooling Package” for customers’ high-precision extrusion blow mold needs. Left to right standing in the back row: Sean King, product design manager; Dan Lobbestael, director of manufacturing; David Swan, VP of mold technology; and John Dudley, manufacturing manager. Seated: Dave Yenor, VP of business development; Pete Lobbestael, senior VP; Crystal Page, controller; and Dave Bearce, mold design manager. Source (All Images): Mid-America Machining

Who is Mid-America Machining?

Peter Lobbestael, senior vice president, Mid-America Machining: Mid-America Machining was established in 1988 by Mark Berry. Initially, the company focused on manufacturing extrusion blow molds and tooling as a contract supplier. In 2002, Mid-America expanded its operations by establishing its own sales and engineering staff, enabling the company to operate as an independent mold supplier.

Over the following decade, Mid-America experienced significant growth and expanded to over 100 employees, operating in a 60,000-square-foot facility located in Brooklyn, Michigan. The company's primary focus is on manufacturing extrusion blow molds and tooling for consumer packaging of up to 5 gallons in size.

Mid-America Machining manufactures extrusion blow molds and tooling for consumer packaging of up to 5 gallons in size. For example, this extrudable PET (EPET) mold used to make extrusion blow molded (EBM) clear bottles that can be recycled with the standard PET stream.

You secured patents for several cutting-edge designs and techniques. What specific challenges did the company face during its transition from a contract supplier to a standalone mold supplier and how were they overcome?

Lobbestael: When we started, we had 12 employees but no customers. Our first challenge was to introduce ourselves to potential customers and gain business. As a new supplier, we faced obstacles due to being unknown but it also gave us the opportunity to establish our brand based on quality and on-time delivery.

A set of trim tooling used to remove excess material or "flash" from a molded part after it comes out of a mold.

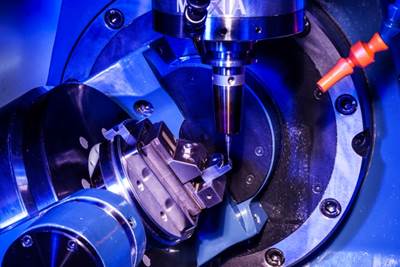

Another challenge was the lack of capital and acquisition of equipment to manufacture the extrusion blow molds and tooling. We purchased used equipment from auctions in southern Michigan and refurbished it to use in our manufacturing area. Over the years, we have phased out the original machines and replaced them with new equipment.

Why extrusion blow molds and what has contributed to the company’s significant growth over the past decade?

Lobbestael: Designing and manufacturing extrusion blow molds was our main source of business before becoming an independent company and we had extensive knowledge of that industry.

We can confidently say that we have the best customer base in our industry. From the outset, we proved our reliability as a partner for large-scale programs, leading to strong, enduring relationships with most of our customers that extend beyond our work together.

What do you view as your chief competitive advantage?

Lobbestael: Our competitive advantage lies in our exceptional team of employees. We believe that we have the best engineering staff in the industry, combined with an experienced sales team and unparalleled manufacturing talent.

Engineering expertise guides initial container and mold designs, minimizing downstream changes.

Our engineering team is highly knowledgeable about all extrusion blow molding machine platforms. We produce a complete tooling package for continuous extrusion shuttle machines, wheel machines and reciprocating screw machines. This expertise enables us to consult with our customers before creating the tooling to prevent any potential issues during the blow molding process.

It also guides initial container and mold designs, minimizing the need for modifications during new product launches. Along with our R&D lab, we can test and trial ideas and designs in-house, so we understand the benefits of new designs or shapes before introducing them to the markets in most situations.

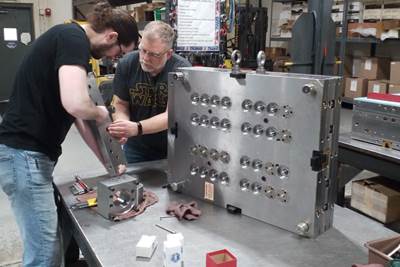

Mid-America Machining has experienced significant growth and expanded to over 100 employees in its 60,000-square-foot facility, phasing out original machines with new equipment along the way.

We also have a remarkable group of employees under 40 years old who will be the future of this business as our seasoned employees prepare for retirement. Employee training and retention are crucial for our future success.

We have implemented a comprehensive mentoring program to support new employees at every stage of their career.

Our approach to manufacturing extrusion blow molds is unique in the industry because we aim to anticipate market needs and create solutions before customers even ask for them. We focus on reshaping designs for mature markets or shapes that have not changed significantly in 40-50 years.

Provide an example of the most significant, recent change in your general approach to business.

Lobbestael: Our approach to manufacturing extrusion blow molds is unique in the industry because we aim to anticipate market needs and create solutions before customers even ask for them. We focus on reshaping designs for mature markets or shapes that have not changed significantly in 40-50 years.

Cornerstone Technology is Mid-America Machining’s unique patent-pending approach to balancing wall distribution in extrusion blow molded containers.

We look for mature markets or designs that have remained unchanged for decades. These packages, having stood the test of time, providing great opportunities for research and innovation. It's usually not a quick process, but we start by identifying the critical features of a package and determining what factors might limit bottle performance or making changes. Then we work on developing a solution to address those issues, proposing changes that require minimal adjustments to customers' packaging lines. Finally, we present our solution to potential customers in that market.

Our first success with this approach was in the dairy industry beginning in 2010, and it continues today with the introduction of our patent-pending Cornerstone Technology family of designs. This strategy has been successful in generating demand for our tooling business.

What is Cornerstone Technology?

Lobbestael: Cornerstone Technology is our unique, patent-pending approach to balancing wall distribution in extrusion blow molded containers, without relying on traditional parison manipulation methods like parison programming or ovalized extrusion tooling to achieve success in high-stretch situations. One exciting aspect of Cornerstone Technology is that the results have been consistent regardless of the container size.

With this approach, we have demonstrated the ability to reduce the weight of rectangular footprint designs by 20-25% while maintaining the existing strength curve from the current package.

Legacy Lightweight family of designs has reduced customer usage of HDPE resin by more than 100 million pounds.

Can you explain how Cornerstone Technology has impacted the dairy industry and what specific benefits it has brought to your customers?

Lobbestael: The lightweight program in the dairy industry is not part of the Cornerstone Technology family of designs. This initiative is referred to as our Legacy Lightweight family of designs, which was initiated in 2009. Over the past 15 years, our customers have reduced their usage of HDPE resin by well over 100 million pounds with the Legacy designs.

What are the most significant ways you expect your business to evolve in the next three to five years in terms of technology, business strategies, place in the market, etc.?

Lobbestael: Over time, we've noticed a significant change in how we interact with brand owners. In the past, we didn't usually work directly with brand owners because they weren't typically involved in the mold and tooling aspect of our business. However, more recently, several brand owners have begun to appreciate the value Mid-America Machining offers to our customers as a high-quality mold supplier.

Mid-America also builds shuttle molds, which enable an extrusion blow molding machine to run two molds at the same time, using one part’s cooling time to mold another part in a separate mold.

Now, with the "right weight" initiatives we've introduced, we've seen the

model evolve to the point where brand owners have a say in designing and developing the bottle before we start manufacturing the production tooling.

Over the past five years, we've experienced an interesting evolution. When we create new shapes, they are generic and not specific to any particular brand. If brand owners express interest, we take the generic shape and add features to give it a branded or family look.

Generally, our initiatives have helped our customers to see solutions from a different perspective than they have traditionally viewed blow molded packaging.

How do you manage to build and maintain trust with your clients while working under NDA/CDA agreements?

Lobbestael: In most markets, we collaborate with major companies. We take great care to keep any new developments or designs confidential and only share them with the specific customer involved. We do not share our development efforts with their current molding suppliers unless directed by our end customers. This approach ensures our confidential developments are only revealed when they are launched in the open market.

Related Content

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreHammonton Mold, ADOP France Forge Strategic Partnership in Injection Blow Moldmaking

Hammonton Mold Inc., a leading full-service mold shop based in New Jersey specializing in injection blow molds (IBM), proudly announces its official partnership with ADOP France, a prominent IBM mold manufacturer based in Normandy, France.

Read MoreCompact Robotic Palletizer Easily Automates Packaging Process

The Cube cell, complete with a KUKA KR50-R2500 robot, is targeted for small- and medium-sized businesses looking to automate the palletization of their end product.

Read MoreRead Next

North Carolina Mold Builder Works With Purpose and Partnership

Adapting and innovating amidst a change in ownership, doubling sales and maintaining the workforce reflects team resilience and expertise.

Read MoreFather/Daughter Team Takes Mold Business into the Future

Innovation, personalized service and a team’s collective mold manufacturing experience earn customer loyalty for 56 years and set the business up for future success.

Read MoreGrowth Requires Mold Builder/Molder to Shift Tooling Focus to Maintenance, Repair and Replacement

The results of aligning awareness and acceptance across departments to balance new tooling and quick response needs.

Read More