Maintenance Matters: It's the Manager's Fault

Improving worker engagement starts with leadership at the manager level or, in our case, the toolroom manager.

Please don’t shoot the messenger, but in Gallup’s latest “State of the American Workplace” report, Chairman and CEO Jim Clifton proclaimed to CEOs and business owners that: “The single biggest decision you make in your job, bigger than all of the rest, is who you name manager. When you name the wrong person manager, nothing fixes that bad decision. Not compensation, not benefits, nothing.”

His opinion is based largely, I suppose, on poll responses from 2010 to 2012 from 25 million full-time employees across the U.S ranging from managers, executives and officials to installation or repair workers and manufacturing and production workers. Unfortunately, the report does not paint a pretty picture concerning the level of “engagement” among these respondents, based on 12 actionable workplace elements they were asked to evaluate, which have proven links to performance outcomes (see sidebar).

Gallup defines engaged employees as those who are involved in, enthusiastic about and committed to their work and workplace. The poll found that only 30 percent are “actively engaged” in the success of their companies, while 50 percent are “not engaged” by their work or managers, and 20 percent are “actively disengaged” or just not happy at work. The bottom line is that seven out of 10 employees are not actively engaged, which means they work less safely, spend more on healthcare costs, miss work and create quality issues for their employers. All of this costs companies $450 to $550 billion annually.

The 68-page Gallup report is full of explanations and insights concerning how employee engagement is measured, how it drives economic growth and why different types of workers demand different engagement strategies. It’s a great read for anyone who wants to better understand the impact on companies and how to improve engagement levels.

If the numbers are not very promising among the general U.S. workforce, they’re even slightly worse among those who work in the “Installation and Repair” category in which mold maintenance and toolroom technicians best fit. (One could argue that this category does not capture the true job description of mold repair technicians, but you could put them in any of the categories and the engagement picture remains grim.) The numbers provide a snapshot of general repair attitudes: 29 percent engaged, 51 percent not engaged or inspired by their work or managers, and 20 percent actively disengaged. These suggest this group is slightly more discontented than most workers. To make matters worse, the data from the “Manufacturing or Production” category, which includes production-floor folks who run molds, ranks them dead last: 18 percent engaged, 54 percent not engaged or inspired by their work or managers, and 28 percent actively disengaged.

In a nutshell, 71 percent of repair technicians are either cruising through work or trying to make things worse, while the molds they repair are being run and looked after by another 82 percent of folks who really don’t give a hoot about anything job-related. Hmmm. This is not a good recipe for success.

Reversing the Trend

Improving worker engagement starts with leadership at the manager level or, in our case, the toolroom manager. Having listened to shop war stories from more than a thousand repair technicians and hundreds of toolroom managers who have taken our mold maintenance training, I know firsthand of the level of disengagement suffered in toolrooms across the U.S over the years. When we question trainees about their job satisfaction levels, one thing is clear: Motivating repair technicians to keep molds running efficiently demands that a toolroom manager possess more than just experience with building molds or a tooling/engineering background.

Toolroom managers must know how to inspire and motivate a diverse group of workers that could consist of several generations (traditionalists, baby boomers, Generation X and millennials) with different motivational triggers. From what I’ve heard, millennials in the toolroom desire opportunities to learn new skills, and baby boomers want to know that the supervisor cares and appreciates their lifetime of work in the trade by requesting their active involvement in creating mold maintenance manuals. Since we are not all built the same, individual triggers need to be recognized and approached appropriately to get the best from skilled employees and improve their engagement levels.

Too often, managers assume that skilled tradesmen are self-driven and that this type of work should be enough to sustain a higher level of effort. It takes more than skills to perform repetitive, high-level, precision work every day. Managers shouldn’t assume that bench time is the only requirement for not only completely understanding how best to repair and maintain a mold, but for motivating repair technicians to want to do it right with no one looking over their shoulders. Skilled craftsmen can tire of the “just fix it” mandate when there are no metrics to measure or gauge success. It goes without saying that most shops need more effort from repair technicians, but more importantly, they also need it from the toolroom managers. It is this position that holds the keys to attitude, growth and fulfillment not only for the employee, but for the company as well.

Questions asked in the Gallup poll suggest that, to begin to reverse this trend, managers must realize what people want and need from their jobs. The survey asks: Does the mission or purpose of the company make the employee feel his or her job is important? Does the company provide opportunities for the employee to learn and grow? Does the company provide opportunities for the employee to do what he or she does best every day? With those three questions in mind, let’s look at three ways a toolroom manager can develop an engaging action plan to improve employee engagement levels.

1. Measure and report mold performance. It is essential to clearly and consistently communicate where the shop has been and where it is going. The most effective way to do this is to measure and report mold performance and maintenance. Without the ability to measure shop performance, you can never set realistic team goals. Typical shop goals revolve only around meeting preventive maintenance (PM) frequencies in a timely manner, and occasionally mold cavity efficiency or cycle times. This is not nearly granular enough to be challenging or rewarding to skilled repair technicians, who want to see more areas affected when molds are repaired correctly and run efficiently.

Shop metrics a toolroom manager should monitor and publicize include unscheduled-to-scheduled mold stop ratios, product issues (defect types and frequencies), mold issues (types and frequencies), tooling usage and labor hours. Hopefully, your shop has an effective workorder system with standard terms that allow this data to be extracted and posted quarterly in the shop to display and monitor how a department (team) is doing over time. This is a critical first step to begin the culture change and improve employee engagement.

2. Create an environment for learning and growth. Employees will be motivated to continue developing new skills in an environment in which learning and development is a shop priority that can be measured. The key is to emphasize and/or enhance the repair technicians’ skills. For example, managers need to train repair techs to be better troubleshooters and not just tooling replacers by consistently analyzing historical defects to see if a corrective action was effective and how long it lasted. (Corrective action simply refers to actions that are performed on a mold during maintenance and repair.) Troubleshooters look for defect patterns and trends in defect positions. Replacers don’t do this. They just stick in new components without considering the root cause of the failure. Unfortunately, many shops don’t use historical maintenance data to train technicians in proper troubleshooting techniques, so many repairs are only Band-Aids that fix the symptom but do not address the root cause of hundreds of recurring problems.

Continuously replacing mold components for the sake of molding parts on time is a death spiral. Tooling and labor costs remain high and mold reliability continues to be unpredictable, at best. No one benefits in this type of maintenance environment; it only sustains a firefighting culture. Repair technicians quickly become jaded and fall into a rut that fuels disengagement and promotes a lack of accountability that costs companies millions of dollars. An attitude of being stuck in a dead-end job where bench skills cannot be measured or appreciated is the worst thing that can happen to someone who strives to be, or already is, a proud and confident craftsman.

To avoid this scenario, managers need to accurately measure bench skills as part of job performance reviews with a workorder system that uses standard corrective-action terms, making it is easy to match a term to a specific repair technician. For example, terms such as fit, welded, stoned, polished, measured, cleaned and benched, versus replaced.

Managers also need to serve as mentors who teach new skills and make suggestions without damaging sometimes-fragile egos and confidence levels. It is important to resist the temptation to harshly criticize mistakes and instead ask “How can we make this easier for you?” or “What do you need to perform this task more accurately?” This approach will promote higher job satisfaction and continued learning and growth opportunities.

3. Set technicians up for success. Maintenance technicians are typically gadget people who love the physical and mental challenge that comes with maintaining complex, precision and expensive mechanical things such as injection molds. To do this to the best of their ability requires managers to set them up for success. This entails making sure technicians are equipped with the right hand and machine tools, proper bench design and easy access to utilities, along with proper lighting, and ultrasonic or dry ice cleaning tools. Their ability to implement safe, accurate and efficient repairs is necessary for personal and shop success. Workorder systems must provide value through accurate reports (standard terms) and be easy to use in order to continually keep the drive for success alive.

In my experience, one method that works well across generations is assigning a dollar value to the type and frequency of corrective actions that are required on a mold. Everyone appreciates seeing costs go down. When a shop can measure what is done to a mold against its performance, the results of a job well done can be accurately determined. This is done by dividing mold run time by the total cost of maintenance (tooling and labor) to get a maintenance cost per run-time hour. This calculation is an easy one to monitor and post in the shop.

Over time, this helps measure the success of specific skills that were learned and applied to improve mold performance as well as show what a person does best. Skills measured from a cost-savings perspective feed enthusiasm and reinforce commitment. A firefighting culture, however, only focuses on molds that don’t run well and leaves no time or data to recognize individual skills that contribute to molds that do run well.

When developing technicians, it is important to have a formal method for demonstrating the correct process for maintenance, such as the eight stages of mold repair. This method allows new technicians to have a foundation for repair from which to build. When work is performed in the proper stages, measuring the results becomes easier. Through our training, we have found that skilled tradesmen want to be measured/compared to a shop standard and then recognized for higher-level work. It is in their DNA, so to speak. Too often, craftsmen work in isolation and are not in sync with shop goals or best practices. It is imperative that skilled tradesmen understand exactly how their work affects product quality and mold reliability on a daily basis. Some skill metrics to measure annually include total number and types of molds worked on, tooling dollars spent (average per mold), labor hours required (average per mold), corrective actions implemented (totals and types), bounce-backs (molds that were returned to the shop for issues after running fewer than 24 hours), defects discovered that were not noted on a repair work-order, and repeating defects that were not corrected properly during repair.

The Gallup poll findings support the concept that toolroom managers and supervisors are the cultural leaders and pacesetters of the shop and are critical to employee engagement, working environment and overall toolroom efficiency. As the report states, “Measurement without targeted action is useless.” For moldmaking, that means that simply handing out workorders for the hot jobs of the day and only measuring the PM completion rate is not enough. Measurable metrics are needed to grow and sustain a higher level of accomplishment in today’s toolrooms.

The final paragraph of the report says it best: “When leaders in the U.S. (or any country, for that matter) wake up one morning and say collectively, ‘Let’s get rid of managers from hell, double the number of great managers and engaged employees, and have those managers lead based on what actually matters,’ everything will change. The country’s employees will be twice as effective, they’ll create far more customers, companies will grow, spiraling healthcare costs will decrease, and desperately needed GDP will boom like never before.”

Related Content

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreRead Next

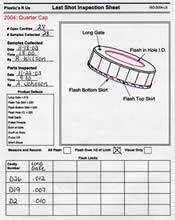

Across the Bench - Creating a Repair Plan

The last shot is the most important key to insuring accurate mold repair.

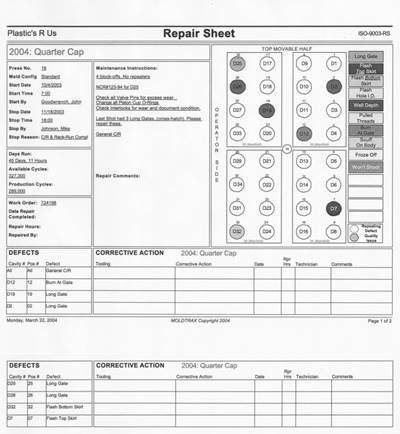

Read MoreAcross the Bench - The Plan Comes Together

The repair sheet is critical to the success of any mold repair plan.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More