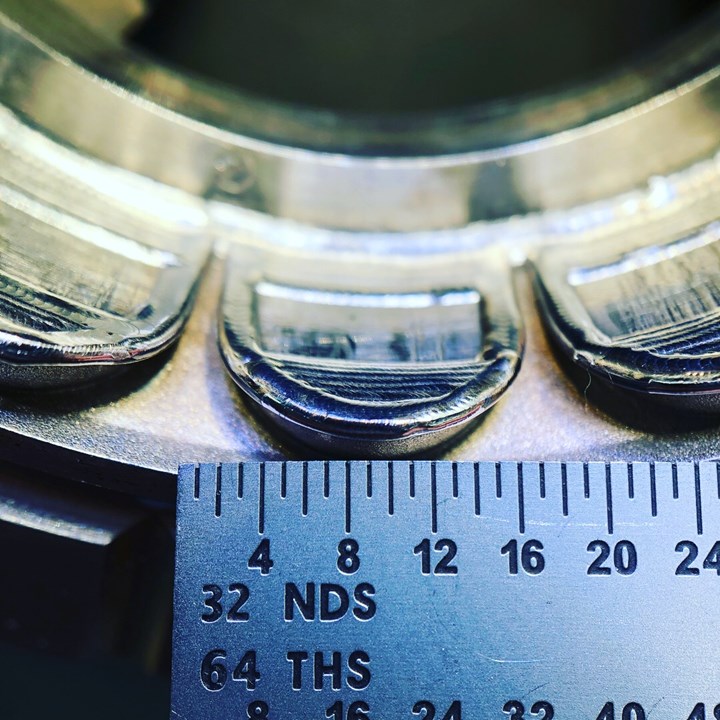

Precision welding repair entails using laser welding to reestablish the entire shutoff edge on a round cavity of an injection mold. Photo Credit: Lewis-Bawol Welding

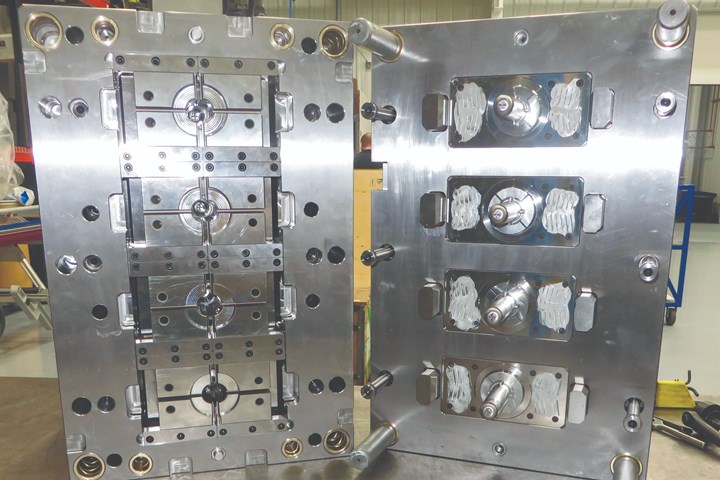

MoldMaking Technology’s 2019 Leadtime Leader award winner, X-Cell Tool & Mold Inc. of Fairview, Pennsylvania, specializes in the design and production of high-cavitation injection tooling—single face, unscrewing, stack, three-plate, liquid silicone rubber, metal-injection molding and reel-to-reel molds—with or without conformal cooling. Most of the tools the 25-year-old company builds in its 45,000-square-foot/4,181-square-meter facility near Lake Erie are in steel and sized for presses ranging from 7 to 728 tons. X-Cell samples 100% of its tools on in-house presses before shipping and has added low-volume injection molding capacity to its services to keep those presses busy. Customers hail from the medical device, consumer products, packaging, electronics and telecommunications markets, so it’s not surprising the company is ISO-9001:2015, ISO-13485:2016 and AS9100D:2016 certified.

In the case of molds with components that need to be repaired, whenever welding can fix the problem, X-Cell sends the job out to nearby Lewis-Bawol Welding, trusting that company’s workmanship, fast turnaround and fair pricing to help X-Cell’s molder customers get tools back into production as quickly and inexpensively as possible. Photo Credit: X-Cell Tool & Mold Inc.

When Parts Wear Out

X-Cell Tool & Mold Inc. of Fairview, Pennsylvania, specializes in designing and producing tight-tolerance injection tooling—with or without conformal cooling—for medical device, consumer products, packaging, electronics and telecommunications markets. Most of the 40-50 new tools the company builds each year are high-cavitation, steel and sized for presses ranging from 7 to 728 tons. Photo Credit: X-Cell Tool & Mold Inc.

In a typical year, X-Cell produces 40-50 new molds, but it also offers engineering changes, refurbishments and emergency repairs to tools regardless of where they were made. “We're happy to assist our customers with any of their needs—be it on tooling that we originally designed and manufactured or that was sourced to other suppliers,” explains James Cummings, X-Cell general manager. “We apply old-fashioned work ethics to modern manufacturing processes and will do whatever we can to help our customers get their tools back into production as soon as possible.” The company has an excellent reputation for producing high-quality precision tools, but even the best-made components eventually wear and need to be refurbished or replaced. Cummings says that X-Cell nearly always has at least one repair job in its shop—typically for worn or damaged shutoffs, worn gate geometry that needs to be reestablished or damage to molding features. “We’ve performed repairs and modifications to tooling from as far away as Puerto Rico and Mexico, although most of those are coming from customers headquartered in the Eastern or Midwestern portion of the U.S.”

In addition to designing and building new injection molds, sampling those molds on in-house presses and offering low-volume injection molding to keep those presses busy, X-Cell also offers engineering changes, refurbishments and emergency repairs to tools regardless of where they were made. The company nearly always has a repair job in its shop. Typical issues are worn or damaged shutoffs, worn gate geometry that needs to be reestablished or damage to molding features. Photo Credit: X-Cell Tool & Mold Inc.

A good example of this is a recent tool that was shipped to X-Cell for quick repairs. The 32-cavity injection mold, with one hot drop per cavity, was producing caps for pharmaceutical bottles. The tool was estimated to be three to four years old and had seen a lot of action. “This tool needed nearly all of its shutoffs repaired and its gate openings welded and reestablished,” recalls Cummings. “Owing to wear, nearly all the gates had gone out of dimension, which was throwing the tool out of balance and affecting cycle time. Many of the shutoffs had cracks, affecting temperature control at the tips and causing vestiges on some parts each cycle. It looked like some of the shutoffs had been welded before, as when a molder starts recycling spares through the tool.”

In a typical year, X-Cell produces 40-50 new molds, but it also offers engineering changes, refurbishments and emergency repairs to tools regardless of where they were made.

For 67 years, Lewis-Bawol Welding, a service-disabled veteran-owned small business, has offered precision welding to the tool and die industry, servicing customers in the plastics, medical, defense, automotive and energy markets, to name a few. The company has built a national reputation for the high quality, intricate detail and fast turnaround of its work in both TIG and laser welding. According to Kevin Bawol (pictured above), company president and general manager, Lewis-Bawol pioneered the use of micro-TIG welding and was among the first companies to weld under microscopes owing to the need to lay down very-high precision beads that were as small as possible. Photo Credit: Lewis-Bawol Welding

With these problems with the tool’s components, there were only two repair options. The first was to weld the openings shut and then re-machine new geometry again. The second was to start from scratch and machine new components—an option that would cost more and take longer. Given the molder’s need to get its tool fixed and back in service as soon as possible, X-Cell turned to local resource Lewis-Bawol Welding of Erie, Pennsylvania. “Whenever welding is permitted or required on a tool, we send the work to Lewis-Bawol,” notes Cummings. “We’re confident that they’ll take the same ownership and pride in their workmanship that we do here at X-Cell. They’ve been pioneers in precision welding for tool shops for many decades.” He adds that the quality of the workmanship on a welding repair must be the same as if a new component was being machined. “If it’s anything less than that, a new component would have to be made, but welding is much faster—four days instead of four weeks—and it’s much more cost effective, helping molders get their tools back into production far faster.”

“Because the gates had a high polish on them, there couldn’t be any witness lines around the welds, so we had to be sure to leave the smallest footprint possible—almost as though it was never welded at all.”

Welding Wizardry

Lewis-Bawol Welding has offered precision welding to the tool and die industry since 1954 and services customers in the plastics, medical, defense, automotive and energy markets, to name a few. The company has built a national reputation for the high quality, intricate detail and fast turnaround—including the same day—of its work in both tungsten inert gas (TIG) welding and laser welding. According to Kevin Bawol, company president and general manager, Lewis-Bawol Welding has its roots in micro-TIG welding and was among the first companies to weld under microscopes owing to the need to lay down very-high precision beads that were as small as possible. Thanks to evolving technology, laser welding now represents the majority of the company’s work. However, it still offers micro-TIG welding and even provides hybrid micro-TIG/laser welding based on customer needs, geometry and the size area that needs to be repaired.

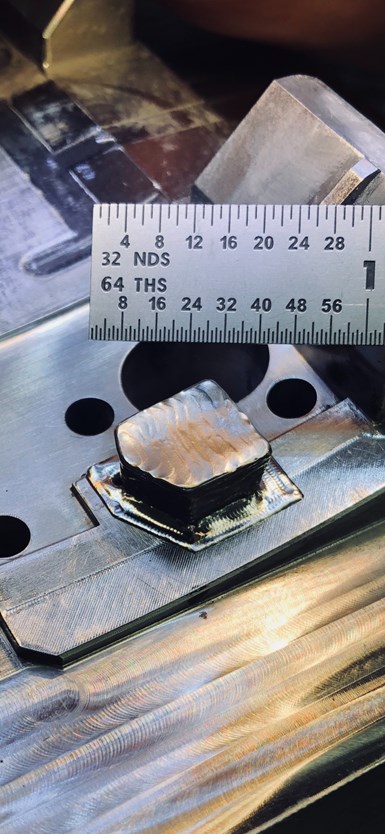

Examples of Lewis-Bawol’s work include this beryllium-copper insert that required a change in dimension, which was accomplished via laser welding. Photo Credit: Lewis-Bawol Welding

“Our state-of-the-art precision laser welding keeps shrink and distortion to an absolute minimum, which we achieve through a combination of advanced techniques developed from over 20 years of laser welding and a thorough understanding of metallurgy,” explains Bawol. “We not only can handle an intricate repair but also a major build on large parts weighing up to 6,000 pounds [2,722 kilograms].” He adds that his team has hands-on experience working with various tool steels, aluminum alloys, aerospace alloys and even precious metals. “In cases where we haven’t worked with a metal before, we can cross-reference or match the manufacturer’s specs,” he adds.

Nearly every day, the company receives shipments of mold components from around the country and the world that require welding for repair, or team members are called into a nearby shop to quote a job. On average, they receive rush projects from X-Cell two to three times per week. “We work with a lot of integrity and pride ourselves with having clear communication with our customers about everything from our expectations of the work we will produce to pricing,” Bawol adds. “We know how important it is for X-Cell and all of our other customers to have their jobs completed quickly and precisely, so our team is committed to delivering whatever turnaround is requested, even when that requires us to work extra hours.”

For this latest project from X-Cell, the Lewis-Bawol team cleaned up every gate and shutoff, prepped them for welding—with some components requiring light machining via pencil grinder to remove old welds—then used laser welding on both sides to seal gate openings and repair the shutoffs. “Because the gates had a high polish on them, there couldn’t be any witness lines around the welds, so we had to be sure to leave the smallest footprint possible—almost as though it was never welded at all,” adds Bawol. The job was turned around in less than a day and returned to X-Cell, which, in turn, machined new openings, polished the components, then returned them to the tool, and shipped the injection mold back to the molder in less than four days.

Getting Molds Back into Production Quickly

In this image, a cavity block with a broken post was repaired by Lewis-Bawol Welding by using a combination of micro-TIG and laser welding. Photo Credit: Lewis-Bawol Welding

“We were very pleased with the work that Kevin and his team did on the mold components and the speed with which we got the job back, which allowed us to get the tool back to the customer so he could get back into production quickly,” notes Cummings, who adds that the 3D geometry of the gates was tricky to weld into a contoured surface and the fact it transitioned onto a mirror finish. “If a job like that isn’t done right, you can find pits in the metal when you go to re-machine the gate geometry and you’d have to send it back to the welder to redo or machine an entirely new part. However, we don’t find pits, cracks or weld fractures, which is why we send all our welding to Lewis-Bawol. A strong relationship with a welder of their quality—especially a local welder—is certainly something we appreciate. At times they make the impossible possible.”

Related Content

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreRead Next

The Making of a Movie: 2019 Leadtime Leader Award Winner

A peek inside MoldMaking Technology's video shoot at X-Cell Tool and Mold in Fairview, Pennsylvania.

Read MoreVIDEO: X-Cell Tool and Mold Is MoldMaking Technology's 2019 Leadtime Leader Award Winner

Congratulations! This year the competition for the title was fierce, but X-Cell Tool and Mold of Fairview, Pennsylvania reigned supreme in the end.

Read MoreLeadtime Leader Q&A: X-Cell Tool and Mold on Quality Assurance

The current Leadtime Leader shares an update on its continually advancing in-house quality processes and equipment.

Read More

.jpg;width=70;height=70;mode=crop)