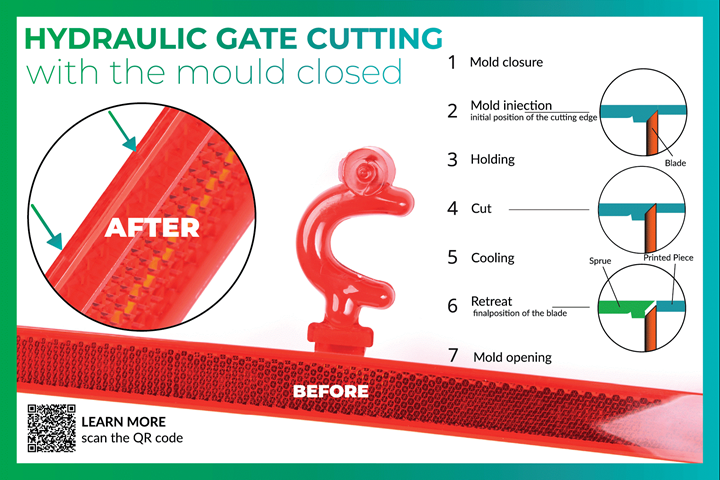

Hydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

Ermanno Balzi Srl has been engaged in the production of components and accessories for molds since 1995. Among the solutions the company offers for the molding of plastic materials is its hydraulic gate cutting technology, which enables the separation of the molded part from the gate during the molding cycle via the axial movement of a cutting tool operated by a mini cylinder.

The cutting, more precisely described as a material displacement, is carried out in a closed mold at the end of the holding phase when the polymeric material is still hot. The high pressure required by the process can be provided through a hydraulic power unit or a pressure multiplier applied to the mold and controlled by the injection molding machine.

There are multiple advantages in this production process, including the elimination of external cutting equipment; repeatability of a cut with high aesthetic quality; the possibility of using larger injection points without requiring external gate removal systems; and the elimination of risks for the operator during manual gate removal. Applications with different materials and types of gates are possible, including film and diaphragm injections.

Related Content

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

Plastic Injection Molder Debuts EOAT, Mold Monitoring Solutions

NPE2024: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.