Maintenance & Repair

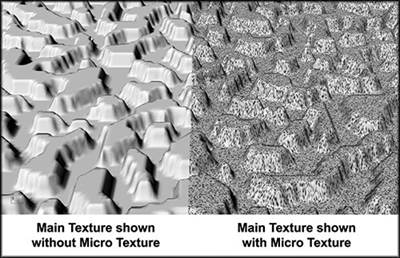

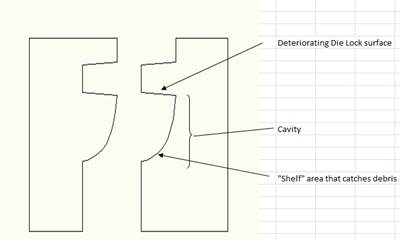

Understanding Texture Repair

Developing a texture repair plan will help get a damaged mold up and running.

Read MoreIn the Trenches: How Not to Troubleshoot, Part 2

Lessons learned when a legitimate corrective action is not performed.

Read MoreIn the Trenches: How Not to Troubleshoot in Mold Repair

In mold repair “really important” refers to correcting problems, not just working around them.

Read MorePlating and Maintaining Textured Surfaces

Communication with your texturing and plating sources is key to properly maintaining the mold surface.

Read MoreIn the Trenches: The Trouble with Troubleshooting

A look at the obstacles to effective troubleshooting.

Read MoreStaying One Step Ahead of Customer Needs

The key to optimal customer support for any mold manufacturer is doing more—from upfront design engineering during the initial stages of product development to emergency mold repair services. And this is exactly the business model Kansas City-area blow moldmaker Creative Blow Mold Tooling offers.

Read MoreIn the Trenches: The Next Step in Minimizing Press Downtime

A look at crib notes on press operation for mold repair personnel.

Read MoreIn the Trenches: I Need a Crash Cart in Here

A look at what you may want to stock in your facility’s “crash cart” to respond appropriately to press emergencies.

Read MoreMold Cleaning Done Right Takes a Systematic Approach

Mold cleaning is just one part of a systematic and comprehensive approach to mold maintenance. Here’s one moldmaker’s strategy for injection mold cleaning and an explanation of where and why different techniques are employed.

Read MoreEfficient Maintenance Requires a Calculated Plan

Advancing from a mold repair culture to a mold maintenance culture can only be fully supported with a companywide understanding of what the real costs are and what the real potential savings can be.

Read More