Efficient Maintenance Requires a Calculated Plan

Advancing from a mold repair culture to a mold maintenance culture can only be fully supported with a companywide understanding of what the real costs are and what the real potential savings can be.

Ask a manager at an injection molding facility to self grade their mold maintenance department. Is it an A (a highly systemized, highly organized, highly standardized data-driven shop) or is it an F where a firefighting culture is the norm?

More often than not, the self grade would be a D or F, versus an A or B. Follow up that question by asking what that less-than-optimal maintenance environment costs the company each year, and it becomes clear that it’s not thoroughly quantified. While managers may often have walking around numbers in mind (for example, cavitation percentage targets, financial targets), when it comes to what the lack of a proper maintenance system is costing a company, it hasn’t been calculable.

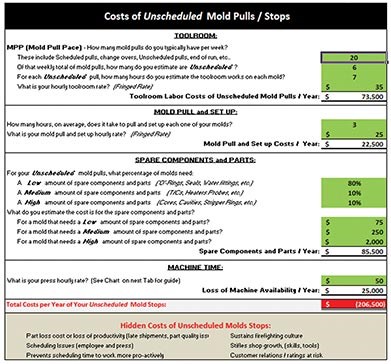

We at mold maintenance training provider ToolingDocs sought to put a number on this cost in order to help the financial minded people within a molding company to justify developing advanced mold maintenance practices, or not.

Most companies have turned over a lot of rocks to look for savings within their companies, but when it comes to mold maintenance, it’s this huge unknown. Most record keeping is either handwritten or electronic journal entries, where putting a cost on metrics such as defects, corrective actions and unscheduled stops is difficult.

To answer this challenge, a unique calculator was developed that enables companies to benchmark what it costs them and, as a result, justify the need to improve their systems.

Making real advances towards a proactive culture requires the ability to show issues and solutions as dollars and cents, otherwise most arguments for improvement fall on deaf ears.

Glenn Keith, Machine Shop Manager for Whirley-DrinkWorks says, “Mold maintenance is often seen as a necessary evil. The finance people may only see the bills from spare parts, labor and overtime, but together we haven’t been able to articulate cost justifications of additional equipment, manpower and training. Despite being as close to it as I am in this company, I’d be hard pressed to put detailed numbers on the actual cost of not having proper systems in place so that I could then put in a request for more resources.”

By filling out the calculator with actual data from one’s plant, one couldn’t dispute the conclusions.

Randy Winton, ToolingDocs’ Global Assessment Manager, has gone through the questions addressed in the calculator with customers who are plant and tooling managers. “No one who has input their data in the calculator has disputed the dollar amounts that have resulted,” he says. “In fact, they’ve expressed great interest in the calculations—some of which have exceeded a million dollars annually in costs that, having now been identified, can be targeted for reduction. It’s a very useful tool that lets a molder understand the broader scope of how much unscheduled mold stops are costing them annually.”

Once a number is known, where does one go from there? Is it an overwhelming endeavor to bring that number down? With the overall opportunity that a molder can now calculate, what is the best way to attack the issues?

Look for low-lying fruit. Start tracking unscheduled mold stops, and develop a plan from there.

“The first thing we did was get some training, and being a tool room manager I wanted to hear a fresh perspective on a documentation system, optimized shop floor layouts, and what we might be able to do as a kind of quick kill and not be left with some huge initiative that might be daunting to execute,” states Chris Gedwed, who is General Manager of Operations at Cosmetic Specialties International.

He continues: “We coupled our MRP system with using a maintenance tracking system for logging in our mold data. That allowed us at any given moment to identify the top five reasons for unscheduled mold stops, as well as the top five problem child molds. With that known, we were able to do several things. First, we could use the information for stoppages as part of our company-wide continuous improvement system and put the visibility up there across all departments that we were going to lead reducing these costs for mold stoppages and involve other departments as necessary. That allows us, as a company, to all be rowing in the same direction to address and eliminate repeated downtime for repeated reasons.”

Then, by identifying the top five problem child molds, CSI was able to target those molds for a more thorough condition assessment when they came out and let every repair technician in the shop know that these molds needed more than just a cursory PM.

“Rather than just doing the bare minimum to get the mold back in the press, only to see it come back again sooner that it should,” says Chris, “we took the time and put a few dollars into the mold because we were able to justify not having further cavity shutoffs or mold stoppages ahead.”

“It’s the ‘pay me now or pay me later’ scenario,” says Keith. “Many times there are pennies-on-the-dollar opportunities for a mold to get up to performing how it was originally intended to. We’ve seen it where, more than just disassemble, clean and assemble, we’ve sent out a mold frame for cleaning and nickel plating, completely rebuilt cavity inserts that have been frequent flash points, and replaced some originally made lifter components with more reliable, standardized tooling. Many times it’s better to bite the bullet and reinvest in the tool and change the cost course that it’s on.” But the actual maintenance and mold performance costs need to be justified to get this done.

“When you can look at the money going into the corrective actions and lost production you then become truly data-driven,” states Gedwed. “So by using the data to make decisions, you start to fix things and become less reactive. The end result is that you save money and feel confident knowing that the problem won’t repeat.”

Furthermore, it’s not just the cost of maintenance and spare parts replacement. Other ramifications can result like late shipments and quality issues in the field that can threaten relationships and confidence with customers.

I’d wager that UPS and Fed-Ex would be able to calculate accurately what it would cost them if their fleet of trucks were on the side of the road with their hoods up. Similarly, we have to calculate accurately the cost of maintaining our fleet of tools in order to make profitable decisions.

In a perfect world there would be no such thing as mold repair—only proactive maintenance. Molds would run and be maintained in such a way as to never break down or make bad production while maximizing tooling life. However, in the real world, advancing from a mold repair culture to a mold maintenance culture can only be fully supported by beginning with a companywide understanding and agreement on what the real costs are and what the real potential savings can be—and then setting one’s course for that target.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreRead Next

Five Principles that Drive Mold Maintenance Efficiency

Individuals from companies that have embraced systemized mold maintenance share their stories.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More