Maintain

Across the Bench - The Plan Comes Together

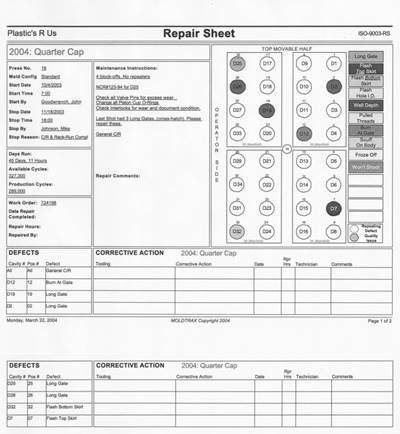

The repair sheet is critical to the success of any mold repair plan.

Read MoreMoldmakers: The First Line of Defense

3-D flow analysis allows moldmakers to identify problems in the mold before they become costly.

Read MoreMinnesota Mold & Engineering Group: Strength In Numbers

Four companies unite-serving as a one-stop powerhouse for art to part and anything in-between.

Read MoreAcross the Bench - Creating a Repair Plan

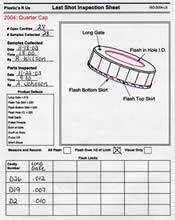

The last shot is the most important key to insuring accurate mold repair.

Read MoreAcross the Bench: Let the Run Begin

Setup checklists, verifications and injection mold layout sheets are critical factors in the beginning of the mold process.

Read MoreTough Coatings Control and Extend Mold Life

Moldmakers can solve tough productivity problems by applying next-generation coatings.

Read MoreFive-Step Process Accelerates Part-to-Production Leadtimes

With mold commissioning analysis technology and melt rotation technologies, multicavity molds can now be commissioned faster to meet the critical time-to-market timeline, while achieving cost savings and continuous improvement in all aspects of product, process and productivity.

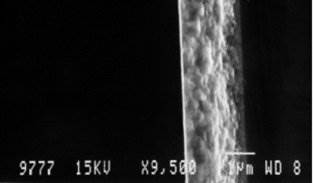

Read MoreHow to Choose the Right Welding Option

When comparing microscopic laser welding and microscopic TIG welding, both have distinct advantages and disadvantages.

Read MoreTechnology and Skill Are Keys to Mold Shop Success

In a driven and changing mold industry, a secret weapon has helped one mold shop to excel and grow.

Read MoreAcross the Bench: One-Man Solution

A tool specifically designed to make tooling removal a quick, safe, one-person job helps moldmakers get jobs done quickly and efficiently.

Read More