Maintain

How to Determine the True Cost of Your Molds

When considering the purchase of a mold, the wrong question is "What is the price of this mold?" The right question is "What is the total cost-to-manufacture for this product?"

Read MorePart Three of a Three-Part Series Setting Up Shop

Mold handling and the overhead hoist system.

Read MorePart Three of a Three-Part Series Laser Beam Hardening: A Flexible Tool for Wear Protection

The development of a new laser beam scanning system for the heat treatment of tool steels and various metals.

Read MoreA Shortcut for Improving Toolroom Efficiency

Developments, strategies, processes and technologies are available to help ensure an efficient toolroom.

Read MorePart Two of a Three-Part Series Setting Up Shop

Determining repair shop space requirements.

Read MorePart Two of a Two-Part Series High Power Laser Technologies And Moldmaking

Using high power laser cladding for rapid tooling and tool repair.

Read MoreHow to Select the Right Microwelding Service Provider

Teaming with the right provider can make all the difference for a mold shop.

Read MorePart One of a Three-Part Series Setting Up Shop

Just as important as creating a solid maintenance plan for molds, is the shop in which the repair takes place.

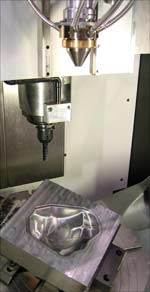

Read MoreEliminate Multiple Toolpaths With Interleaving Technique

Intelligently applying the right style of toolpath in the right place in a single pass is achieved with an interleaving technique.

Read More