ProLink Molds: Up and Running!

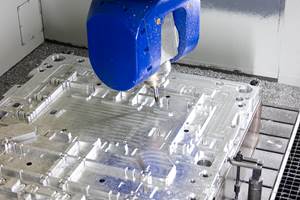

This brand-new moldmaker offers molds complete with the company’s own hot runner technology to better meet its customers’ needs.

Last year, a duo of experienced industry professionals from different companies—

who shared the same values toward quality, service and forward-thinking business strategies—got together and decided to start a new company to merge their philosophies into one.

ProLink Molds (Oakville, ON) not only designs and manufactures molds, it has its own line of hot runner systems to accompany its mold technology. And, the company has developed a proprietary “Global Shop Floor” system to reduce costs and ultimately allow the company to provide its customers with high-end quality tooling at international competitive prices. The 15,000-square foot manufacturing facility supports research and development as well as design concept creation to manufacturing and final assembly. The company also has technical support agents in the U.S. and South America.

The founding members decided its niche of precision multiple cavity injection molds because they bring years of experience in this specialized area and they both believe that these complex, intense, knowledge-based projects will be their competitive advantage. “These are complex molds that require extensive knowledge in mold design, limiting the number of moldmaking firms that can produce these challenging molds,” notes ProLink Molds Marketing Manager Bruno Gomes. Furthermore, the duo decided to target the cosmetics, caps and closures, medical, pharmaceutical, consumer products and thin-wall product markets.

According to Gomes, this brand-new company offers part design and development, prototype tooling, R&D coordination, mold and hot runner design and manufacturing, testing, part samples, and an S3 Link Program the company created that allows customers to purchase a complete integrated processing operation from one supplier.

Technology Triumphs

ProLink Molds’ hot runner technology—in conjunction with its molds—offer customers a one-stop shop, Gomes emphasizes. “Our designs, which are the heart of every project, provide customers with simple, yet high quality performance and efficient technology at international competitive prices,” he states. “Our advantage is the simplicity, low maintenance, interchangeable, per-forming products that can optimize processing conditions for molders while reducing downtime for maintenance or component changes.

The company recently introduced its hot runner technology to the Brazilian market. Gomes explains that the company founder owns the patents in Brazil, and has found that the Brazilian market of injection molders are demanding a higher level of technology to increase their efficiencies and are demanding “sophisticated and performing mold solutions.”

The company also has developed specific technologies like collapsing core mechanisms, mold slide features, and hot runner nozzles designs that target a specific market and application—again allowing customers to take advantage of products that are specifically designed to meet their exact needs.

Business Acumen

In addition to technological advancements, ProLink Molds has made strides on the business end—developing a strategy that moves away from traditional business practices and procedures within the moldmaking industry called the Global Shop Floor, which uses the power of communication technology and adapts a more open philosophy mentality with customers, suppliers and competitors.

“We have established a network philosophy that concentrates on mass collaboration,” Gomes comments. “Through strategic partnerships and supply chain management, we focus on developing our value-added activities and leveraging the competitive advantages of our partners. This has allowed us to concentrate solely on improving areas that are our competitive advantage, while leveraging the competitive advantages of our strategic partners.”

Recently, ProLink Molds formed a strategic alliance with Ryka Molds, Inc. (Mississauga, ON)—a manufacturer of blow molds for the packaging, industrial and automotive applications—and Domavista Enterprise, Inc. (Mississauga, ON)—an R&D firm. “This alliance strategy is part of our Global Shop Floor vision where each company integrates their products, services and knowledge to ultimately provide more options and value-added solutions to their customers. Ryka Molds is a respected company known for their quality blow mold technology and Domavista possesses extensive experience in the areas of design and research and development. As a group, we can offer a customer a complete integrated product solution with full technical support and experience throughout the whole process. We must recognize that we are not capable of doing everything, but we also must realize that in order to maintain value to the customer we should support them with customized solutions for all their needs. For example a customer can receive specialized support in product or design development, a blow mold for a bottle and an injection mold for their cap—ultimately receiving an optimized and integrated solution.”

This, in turn, helps the company reduce costs and better compete internationally. “We decided to re-evaluate our process and look at cost cutting strategies, without having to lose any of our team members. This led us to develop our business model strategy. We focus our energies on developing and enhancing our knowledge-based work, which allows us to be cost efficient by working closely with our suppliers.”

Investing in Employees

Without a solid relationship with its employees, ProLink Molds would not be able to develop and implements its innovative technologies and business practices. The company holds regular meetings that focus on discussing any new technology or industry news that has been read in industry magazines.

“From these meetings, we all gain information of current industry news and attempt to find and define areas of opportunities for our company,” Gomes says.

In terms of training, ProLink has emphasized that developing individual skills and knowledge will benefit the team member, which will ultimately benefit the overall good of the team. “We look to promote from within, so whether it be management training or technical training, if we see commitment and a proactive attitude toward further developing one’s skills, we will support these ambitions,” Gomes comments. “Lastly, our human resources department is looking at developing new techniques like reward programs—internal competitions that promote advancements and performance that will add onto our existing programs. We keep our team members satisfied by attracting people who enjoy and fit our organizational culture. Rewards, recognition, events and work-related competitions also add to creating a cohesive and performing workplace.”

In order for this trend to continue, the company is currently reevaluating its recruitment methods for new team members seeking employment.“We realize that having the right and capable people that fit our organizational culture will be the key to our success and reason for excelling. This is why we are restructuring our recruitment process from job advertising to employment contracts. Part of this restructuring has led us to develop a system of consensus—where applicants will be reviewed not only by management, but more importantly departmental team members. Review of skills and experience will still be highly relevant, but personality and character attributes will be measured and evaluated by various members from our organization.”

The Road Ahead

One of ProLink Molds’ goals is to further develop and expand its Global Shop Floor philosophy to its maximum potential. “Being a fairly new company, our goal currently is to market and show how our products and services can truly save customers money on their mold and hot runner requirements while enhancing their operations,” Gomes says. “We will work toward establishing more relationships with strategic partnerships worldwide to increase our global support.”

The company is currently in discussions with a recognized and respectable company within the plastics industry regarding the possibility of establishing a strategic partnership. While declining to name names, Gomes notes this partnership will be very beneficial for both companies as their products, markets and technologies will complement each other quite well. Additionally, this partnership will support the Global Shop Floor vision and allow both partners to leverage each other’s know-how and competitive advantages to increase their offerings and services to their customers. ProLink also has started working on developing a new product that will complement its hot runner product line, giving its customers more options and solutions for their molding system needs.

“Our vision for the future is one that focuses on winning,” Gomes emphasizes. “This means winning for all members involved—from partners, suppliers, customers, team members and society. Plastics is a large and important industry supplying many products that we use in our daily life. Our company wants to be part of this growing industry and contribute to it by focusing on creating win-win relationships; innovating and adapting new technology that proves beneficial; and constantly developing new strategies that will benefit our Global Shop Floor vision and all members involved. As former CEO and Chairman of General Electric Jack Welch once said, ‘You can only contribute to social responsibility when you are winning.’”

Related Content

CAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreTrue Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreLaser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved their tool room efficiency when it comes to difficult welds and urgent repairs.

Read MoreRead Next

Tech Tool & Mold, Inc.: Staying Focused

This moldmaker’s firm belief in continuous education for its employees combined with advanced training and cutting-edge technologies increases total delivered value of its products.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More