Hot Runners

Component Supplier Ramps Up Support during Crisis

Expediting all work and supplies for Coronavirus projects is key to this mold component supplier They have first priority. “Many of our customers are in the medical field and they need support from us.

Read More8 Ways to Increase Mold Life

A checklist of molding machine settings and preventative maintenance actions that improve mold longevity.

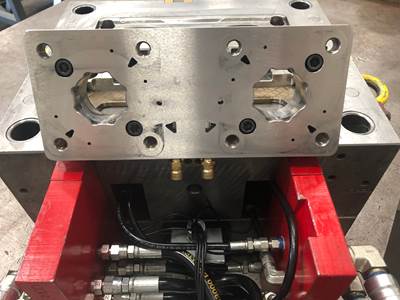

Read MorePneumatic Cylinders Install Without Removing the Hot Runner

HRSflow announces its extended portfolio of compact and small cylinders which require limited installation space.

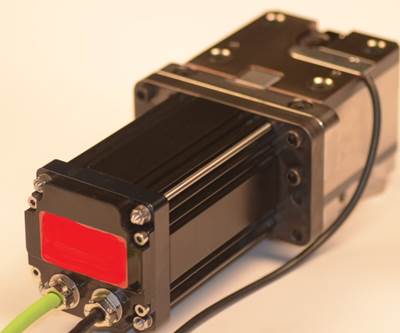

Read MoreHow to Correctly Diagnose Hot Runner Electrical Issues

Watch to learn how misdiagnosing temperature control issues caused by defective or incorrectly wired components can make finding root cause and solving the problem difficult and time consuming.

WatchHow to Make an Informed Hot Runner Decision

A proper hot runner assessment requires evaluating and calculating key runner system variables.

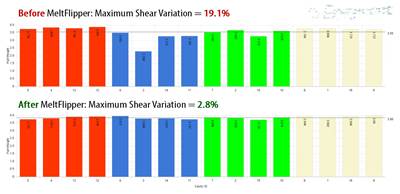

Read MoreDigging into Data to Design Out Fill Imbalance Problems

Injection molder uses a custom runner design to reduce shear-induced imbalances and control shrink and warp, dimensional instability, and shot-to-shot inconsistency.

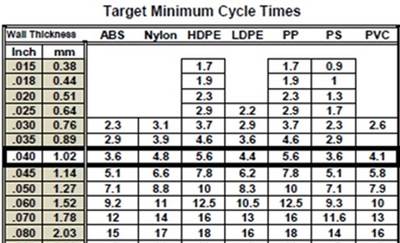

Read MoreHow to Use a Conformally Cooled Sprue Bushing to Reduce Cycle Time and Ease Cost Pressures

Use of a new conformally cooled sprue bushing helped solve Midwest Mold Services’ problem with a big sprue that was hard to cool and preventing faster ejection times.

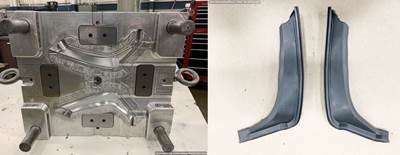

Read MoreAdditive Tooling Goes Beyond Conformally Cooled Inserts to Simplify the Mold Build Process

Three ways that additive tooling is moving past conformal cooling to bring speed and efficiency to the overall tooling process.

Read MoreOnly an Educated Buyer Can Reap the Rewards

Choosing the right electrically-actuated hot runner system is important, so is asking the right questions upfront to better understand what you are buying. It’s easy to be sold on all the fantastic benefits you could see, while looking passed the downsides of the system you are choosing.

Read MoreWorkflow and Quality Count

A recent visit to a hot runner systems and solutions provider proved the importance of workflow and quality to a production facility’s layout.

Read More