Hot Runners

Integrated Cascade Control Unit Ensures Control Over Melt Flow

Conscious of space, the integration of VCON with the profiTEMP+ in one cabinet enables independent valve gate nozzle adjustment for more control.

Read MoreExpanded Hot Runner Nozzle Series Focuses on Melt Guidance

Meusburger’s offers its expanded smartFILL nozzle series focusing on melt guidance.

Read MoreServo Valve Gate System Advances Injection Molding Process Control

Electrically driven, HRSflow’s Flexflo Evo technology is a ready-to-install system, specifically designed to set and monitor the valve pin position during the injection process.

Read More2020 Sourcing & Technology Guide: Hot Runners

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services with 11 sections, including Hot Runners.

Read MoreValve Gate Hot Runner System Provides Common Design Platform

DME’s Smart One valve gate hot runner system provides a common design platform.

Read MoreHow to Use Servos and Sensors to Advance Process Control

A servo and sensor combination that makes the mold the machine presents opportunities to advance process control.

Read MoreHot Runner Series Ideal for Molding with Challenging Resins

Mold-Masters/Milacron offers its latest advancement in hot runner technology delivering peak performance and precision.

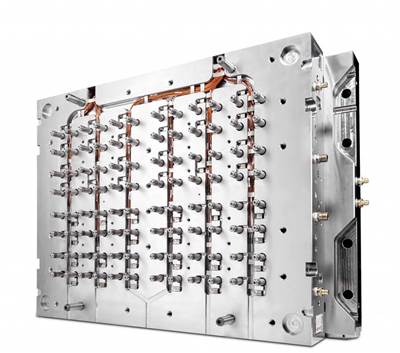

Read MoreMulti-Cavity Nozzle Solution Improves Thermal Profile and Efficiency

Taking advantage of the latest technological advances, Mastip Inc. continues to evolve its multi-cavity and hot-half solutions with a series of innovations and product upgrades.

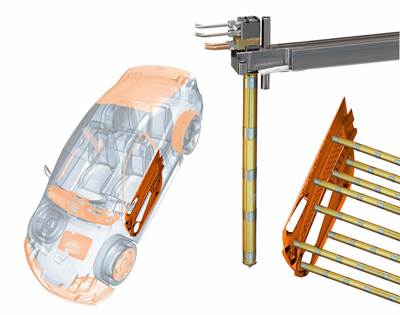

Read MoreHRSflow is Global Market Leader for Automotive Hot Runner Systems

Since the fourth quarter of 2019, HRSflow has been the number one worldwide in the field of hot runner technology for automotive applications.

Read MoreCompact Nozzle Design Simplifies Cutout Geometry

INCOE Corporation presents its DF nozzles with MultiPower heaters for the Direct-Flo product range.

Read More