Five Axis

Five-Axis Machining Software Offers Speed and Flexibility

Improvements in five-axis machining software are lowering the barrier for adoption by moldmakers.

Read MoreEquipment Leasing: A Popular Alternative to Buying

Leasing equipment provides moldmakers with more purchasing opportunities during tough financial times.

Read MoreHow to Control Excessive Tool Wear

By calculating feeds and speeds properly, moldmakers can reduce tooling costs, have less machine downtime and see less scrap due to worn tools.

Read MoreChoosing a High-Speed Spindle for Moldmaking

Many factors - such as mounting style and lubrication choices - need to be considered when choosing a high-speed spindle.

Read MoreHow to Lower Leadtimes Through Spindle Retrofits

By adding a secondary high-speed spindle to their machining centers, moldmakers can gain higher speeds at a lower cost.

Read MoreKeys to Small Hole Drilling

By paying attention to the basic rules, moldmakers can solve some common small hole drilling problems.

Read MoreThe Argument for Horizontal Machining Centers

Although VMCs are widely used, HMCs offer more flexibility, versatility and a number of operations in one machine tool.

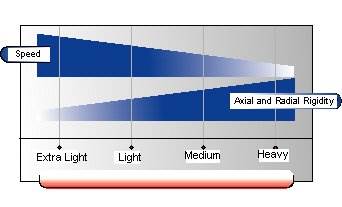

Read MoreBearing Enhancements - How New Technology Can Impact Machine Performance

By paying attention to such details as bearing selection and grease delivery systems, moldmakers may be able to increase machining speeds by up to 20 percent.

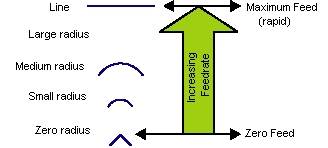

Read MoreBecoming More Accurate With Speed

By adding optimization software to their machining, moldmakers will be able to produce better quality parts with better accuracy.

Read MoreExpanding Business Opportunities With Five-Axis Software

Moving to five-axis machining may seem a daunting maneuver, but with the right software and training, a moldmaker can gain an advantage on the competition.

Read More