Five Axis

Hydraulic Fluid Reduces Energy Consumption by Eight Percent

An energy-efficient hydraulic fluid has been developed for use with CNC machines that features low-deposit forming tendencies, provides equipment protection and can extend oil maintenance intervals.

Read MoreElite Mold & Engineering: Team Elite

Being both a moldmaker and a molder allows Elite Mold to be a one-stop team for its customers and the MoldMaking Technology 2009 Leadtime Leader Honorable Mention Award: Small Shop.

Read MoreHigh-Speed Machining Simplified

How high-speed machining can be reliably achieved by using the principles applied along with the correct tooling, feeds and speeds.

Read MoreMaking the Most of High-Speed Machining

High-speed machining can cut mold manufacturing time in half, but only if it’s executed with an eye to the special needs of the tools and the process.

Read MoreMetalworking Skills Are in Demand Among Green Power Suppliers

Mold shops seeking new business have sizeable opportunities machining parts for new energy systems.

Read MoreConsiderations for a High-Feed Milling Strategy

High-feed milling is becoming the chosen methodology for removing as much material as possible in the shortest amount of time, as more shops equip themselves with high-speed CNC machining capability and sophisticated CAM programs.

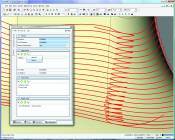

Read MoreSimplified Approach to Complex Five-Axis Machining

As multi-axis machine tools become more complex, CAM software systems must provide a more elegant way to program them.

Read MoreFeature-Based CNC Programming Cuts Programming Time by 25 to 75 Percent

Moldmaker switches to new programming software that auto-matically recognizes features and allows the programmer to define a process for the feature that can be repeated each time a similar feature is encountered; and, allows for more timesavings via its improved rest machining and trochoidal milling capabilities.

Read MoreImprove Process Economics For Roughing Mold Cavities in Hardened Stock

Mold manufacturer improves cavity hogging and debottlenecks key operation on popular hardened stock with a facemill featuring three flutes with 6-sided inserts.

Read MoreThe Benefits of a 4+1 Machining Process

The benefits of 4+1 machining can better the results of 5-axis machining: overall cutter life, cutting time and surface finish are improved.

Read More