Five Axis

Extreme Tool and Engineering: Building Relationships, Fostering Growth

This moldmaker proves that dedication to its customers combined with a will to thrive in a global marketplace is the right formula to win the MoldMaking Technology 2006 Leadtime Leader Award: Large Shop.

Read MoreMachining Molds with Negative Stock Shutoffs

Negative stock shutoff can help you make better molds in less time. Here is a clear definition and description of the process. While the concept is fairly simple, the implementation can be challenging.

Read MoreMaking Lean Work: Autonomation

Transferring human judgment to automated machinery can increase shop production.

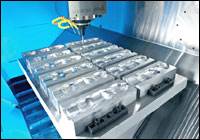

Read MoreThe Keys to Successful High-Speed Machining

Moldmakers will reap all the benefits of high-speed machining with the right mix of machine tool, tooling and programming.

Read MoreMold Building Without Rule Breaking

Push the mold in the beginning of the build process to discover any weaknesses before it gets to the molder.

Read MoreLearn to Compete with Negative-Shape Machining

Moldmakers can reduce costs and increase throughput with a high-technology approach.

Read MoreHow to Exceed the Limits of Your Toolpaths

A moldmaker’s ability to reduce machining time is not limited by his machine tools or cutting tools, but rather by the toolpaths that drive them.

Read MoreHow to Select and Use Your Vertical Machining Center

Competitive shops need to consider the true capabilities of their VMCs to achieve a high level of accuracy and surface finish.

Read MoreTaking Control of Finer Surface Finishes at Higher Speeds

An increased interest in five-axis machining—coupled with advances in controls and cutting tools—add up to finer surface finishes at higher speeds.

Read MoreMoving High-Technology Machining into the Mainstream: Part I

To achieve the maximum ROI, companies must consider the machining strategies they apply and the supporting software, hardware and cutting tools used.

Read More