Engineer

Dental Mold Challenges Are Overcome with the Right 3-D Design-for-Manufacturing Solution

An organic 3-D design-for-manufacturing solution from SensAble Technologies allowed Merz Dental to reduce the process of designing and producing a finished mold for a family of denture teeth from 24 months, to just 6 months, while increasing quality.

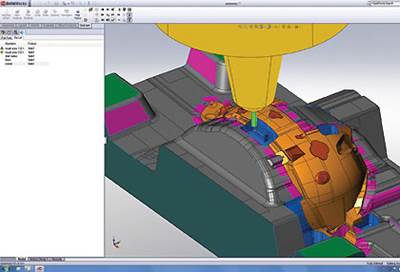

Read MoreIntegrated CAM for Toolmaking

A look at integrated CAM systems, and the importance of placing cost and capability at the top of the list during the selection process.

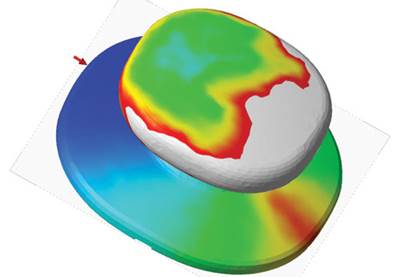

Read MoreLiquid Silicone Rubber Molding Simulation

LSR and thermoset toolmakers are encouraged to make simulation an integral part of the design process.

Read MoreMold Cooling Breakthroughs

“Radical” is not a word one expects to hear from a plastic injection molding company.

Read MoreBaffle Blades in Plastic Injection Molds

Turbulent-flow plastic baffles eliminate blow-by, significantly improving cooling and cycle times.

Read MoreTooling Design for Silicone Molding

One of the biggest challenges in mold design for silicone molding is the runnerless molding system or cold deck.

Read MoreLaser Sintering And Conformal Cooling Channels

Moldmakers who are interested in exploring conformal cooling, but are concerned about its complexity and expense need to understand two things: it is neither complex nor expensive.

Read MoreCAD/CAM/CAE Integration Eases Flow Simulation

Moldmakers benefit from having flow simulation as part of the CAD/CAM environment—reducing the time and effort involved in running a flow analysis study and getting the product to market.

Read More