Integrated CAM for Toolmaking

A look at integrated CAM systems, and the importance of placing cost and capability at the top of the list during the selection process.

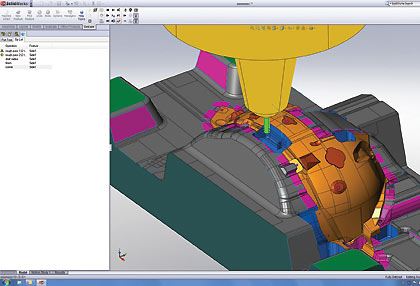

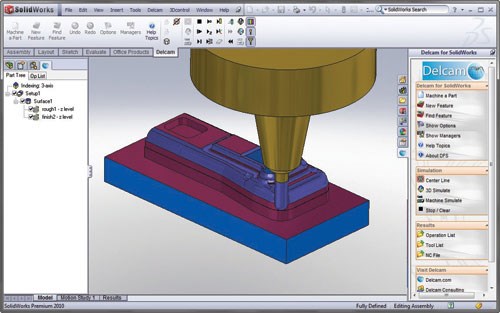

In the early days of the CAD/CAM industry, customers were supplied a completely-integrated system for design and manufacture from a single developer. More recently, stand-alone design systems have become popular. There is, of course, still a need to make parts designed with those systems, so a separate CAM system is required. A number of CAM suppliers now offer programs that can be embedded into the design software. These offer similar benefits to the fully-integrated systems, even though the CAD and CAM elements are developed by different companies.

The Benefits of Integration

The integrated CAM systems offer two main benefits. First, the CAM system must have a similar interface to the CAD software, making it easier for designers to learn the program. Secondly, associativity can be maintained between the CAD and CAM programs with automatic updating of the toolpaths if the product’s design changes.

Associativity is of most benefit at the early stages of a project. For example, when prototype models are being machined or first-run tooling is being made. In both cases, the customer’s main demands are for quick delivery and rapid response to design changes. Associativity offers faster updating of the toolpaths than reprogramming the part and helps to give faster response times.

The efficiency of the toolpaths is less significant at this stage, especially for smaller products. For these projects, the machining will often be undertaken overnight and unsupervised. This means that the prototype or tool will be ready the next morning whether the machining time is four, six or eight hours.

Pitfalls of Associativity

Machining efficiency becomes more of an issue when manufacturing production tooling. With some molds having more than 100 cavities, extra cutting time for each cavity becomes a much more important issue. Furthermore, the production tool will usually be made of a harder material, increasing the possibility of an inappropriate toolpath causing cutter breakages. For both reasons, it can be safer to reprogram the machining rather than relying on the software’s associative results.

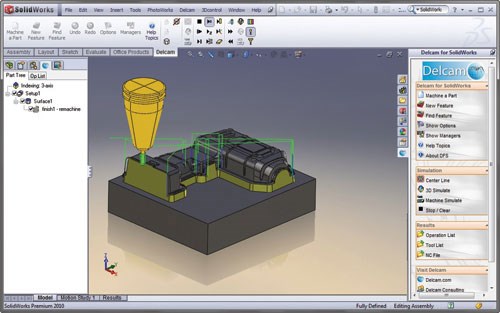

The main problem is that some software will remember the choices it has already made when it updates the toolpath. This can mean that it will continue to use a strategy or cutter size that is no longer appropriate. For example, if the initial design contained a thin slot that is changed to a wider slot, the updated toolpath will still use the small cutter even though a bigger option might have become more suitable.

There are a limited number of CAM systems that offer the best of both approaches. They undertake automatic selection of cutting tools, machining strategies and feeds and speeds for every programming operation. If the design changes, all of these selections are reconsidered to make sure that they are still appropriate for the new design.

It might be expected that this more comprehensive review will lead to an increase in the programming time. Modern hardware developments, such as 64-bit operation and multi-threading, mean that any increase will be minimal unless the part is especially large or complex. In such cases, the associative approach will probably not be the most efficient anyway.

Don’t Forget the Basics

While associativity is an important aspect of integrated CAM, it should not be the only thing to be considered when choosing the most suitable software. The fundamental requirements of cost and capability should still be the most important considerations.

Cost is a much more complex issue than it might appear at first. As well as the software purchase, initial costs will include training and, possibly, the price for post-processors if the company’s machine tools are not covered in the selection supplied as standard with the system. Users should also check whether simulation is included with the system, or whether this is an extra cost, as toolpaths need to be checked on the computer before they are sent to the machine.

In the longer term, support and upgrade costs will be charged. Even though all CAM systems have become easier to use, new customers will usually still require help with more complex projects. Upgrades help the customer to benefit from new developments in the software and also ensure that the CAM system remains compatible with new versions of the CAD program.

The CAD companies run various tests on the different CAM systems and will confirm that the programs are compatible. This provides a degree of assurance to those selecting a system. However, these tests tend to be very general, so a more specific demonstration on the company’s own parts should also be undertaken.

Summary

Using an integrated CAM system will offer benefits, especially to companies making prototypes and first-off tooling. Designers that use CAM occasionally will find the integrated CAM system easier to learn because of the similarity to the interface of their design software. However, this does not override the need to put cost and capability at the top of the list when choosing a CAM system.

Related Content

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)