Engineer

Impact of Hot Runners on Life Cycle Molding Costs

Five factors to consider when selecting your next hot runner solution.

Read MoreSmall Shop HM CS Tool Engineering: The Business Of Customer Service

Despite its location in Cedar Springs, MI—a state that has been hard hit by the economic downturn—CS Tool Engineering, Inc. has landed the 2010 Leadtime Leader Award Small Shop Honorable Mention by constantly investing in technology and offering its customers complete customer service with leadtimes between 10 and 12 weeks.

Read MoreIs It Time for Some Preventive Mold and Hot Runner Maintenance?

Points to consider when planning preventive maintenance on a tool.

Read MoreFrom the Field: Programming Software for Producing Playmobile Toy Molds

If it is still the norm in many tool- and moldmaking businesses to carry out programming either offline or directly on the machine, then the Playmobil example shows that a combination of both provides a lot of scope for creating and implementing new ideas.

Read MoreNew Modeling Partner Product

PowerSHAPE Companion for PartMaker, is based on Delcam’s PowerSHAPE design software.

Read MoreNew CAD Partner for PartMaker, PowerSHAPE Companion

New CAD Partner for PartMaker, PowerSHAPE Companion. Delcam has launched a new modelling partner product for its PartMaker CAM system for turn-mill equipment and Swiss-type lathes.

Read MoreEngineering, Calculation and Reference Resource Software for Moldmaking

DZynSource for Molds software, version 3.0.0, has just been released.

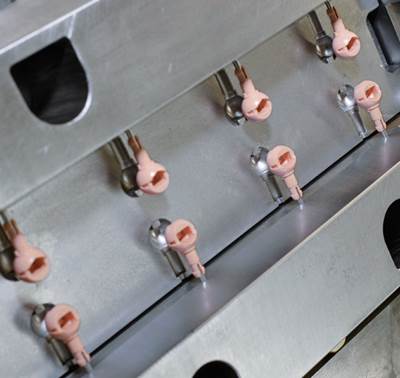

Read MoreEarly Collaboration, Part Design Involvement Key to Global Growth in Packaging

This mold manufacturer has achieved success by partnering with manufacturers in the packaging and closure markets on innovative plastic part designs—not simply providing a mold quote.

Read MoreThe Digital Office: Improving Efficiency and Productivity in Your Back Office

Simple and affordable document management solutions that can have a powerful impact on your shop’s bottom line.

Read MoreAdvanced Toolpaths Improve Cutter Performance in Difficult Materials

Trochoidal toolpaths are available on most CAD/CAM systems, yet are rarely used or even known. By using trochoidal toolpaths and hybrid trochoidal toolpaths you can successfully machine exotic materials.

Read More