Conformal Cooling

May the Force Be with You

Unlocking the true potential of magnetic workholding for machining mold bases and inserts lies in understanding clamping and machining forces.

Read MoreThe Designer's Edge: Stationary Vent Pins and Inserts

Stationary pins or inserts, which are sometimes a necessity to assist with venting, should be designed with ease of assembly and disassembly in mind..

Read MoreHigh-Feed Tool, Deeper Cut?

Thick inserts make a high-feed tool this shop’s top choice for heavy roughing operations as well.

Read MoreSimplify Mold Machining

Use true five-axis simultaneous machining for your molds and inserts.

Read MoreDigital Edition of September's AM Supplement Now Available

This month's issue includes two features. One on repairing damaged mold inserts using direct metal laser sintering and the other on a tool and die and CNC machining job shop with an unusual employee development philosophy that employs additive manufacturing.

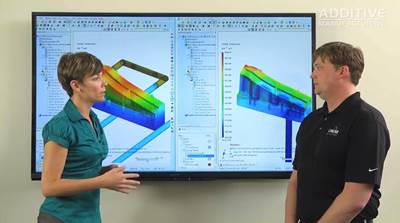

Read MoreMMT Visits Linear Mold to See Additive Mfg in Action

Linear Mold & Engineering opened its doors to us to talk about how they’re using additive manufacturingI to grow conformal cooling channels inside mold inserts and to make production parts for the aerospace and medical industries.

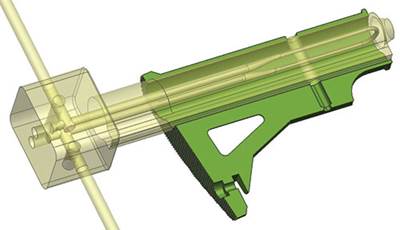

Read MoreComplementing Laser Sintering with EDM

Laser sintering unlocks the potential to “grow” conformal-cooled inserts from the ground up. Wire EDM ensures production proceeds at a pace that keeps up with demand.

Read MoreThe Intersection of Laser Sintering and EDM

For this moldmaker, wire EDM helps streamline production of inserts that are “grown” with cooling lines already inside.

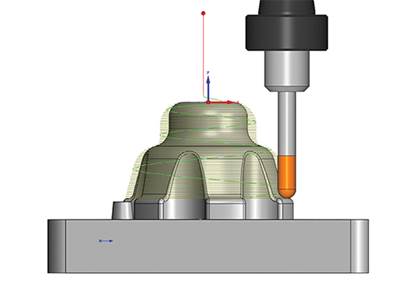

Read MoreMetal Laser Sintering Hybrid Milling

Metal laser sintering hybrid milling combines metal powder 3D laser sintering with high speed milling finishing into one machining system.

WatchLaser Sintering and Milling Working Together

A hybrid manufacturing process offers mold builders an alternative method for making cores and cavities with time and cost savings and increased consistency.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)