Conformal Cooling

Laser Sintering And Conformal Cooling Channels

Moldmakers who are interested in exploring conformal cooling, but are concerned about its complexity and expense need to understand two things: it is neither complex nor expensive.

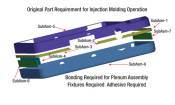

Read MoreReduce the Time and Costs of Jig and Fixture Manufacture

When it comes to the manufacture of jigs, fixtures and assembly tools, time-to-market for new products can be reduced, overall costs can be saved and the quality of the resulting components/production can increase with the use of additive fabrication—laser sintering and fused deposition modeling.

Read MoreWhen to Shift: Conventional Molding or Rapid Manufacturing?

To make intelligent decisions of when to use one process over another, certain considerations must fall into place. This discussion will deal with laser sintering.

Read MoreDirect Metal Laser Sintering vs. Conventional Tool, Part Two

In this head-to-head comparison, conventional toolmaking seemed to be the superior route to go from a cost, quality and leadtime perspective.

Read MoreImprove Process Economics For Roughing Mold Cavities in Hardened Stock

Mold manufacturer improves cavity hogging and debottlenecks key operation on popular hardened stock with a facemill featuring three flutes with 6-sided inserts.

Read MoreDMD Conformal Mold Cooling Lines Offer Reduced Part Production Cycle Times

A conformal mold cooling technology made possible by a new manufacturing technique has been developed to cool molds.

Read MoreStandardized Mold Base Reduces Mold Build Time, Costs

A patented standard mold base—the Lightning Base—uses one common base with interchangeable inserts for various parts.

Read MoreHolders/Cutters/Inserts Combination Maximizes Productivity

A switch in cutting tools triples the output at a die stamping facility.

Read MoreDirect Metal Laser Sintering and Tooling

The applications, benefits and limitations of direct metal laser sintering for mold manufacture.

Read MoreHow to Select the Right Carbide Insert

The menu of available coatings for carbide inserts has expanded ten-fold in the past 10 years. Selecting the one that can produce low cutting forces with smooth cutting action, good surface finish and long tool life becomes the user's dilemma.

Read More

.jpg;maxWidth=300;quality=90)