Complementing Laser Sintering with EDM

Laser sintering unlocks the potential to “grow” conformal-cooled inserts from the ground up. Wire EDM ensures production proceeds at a pace that keeps up with demand.

Share

Read Next

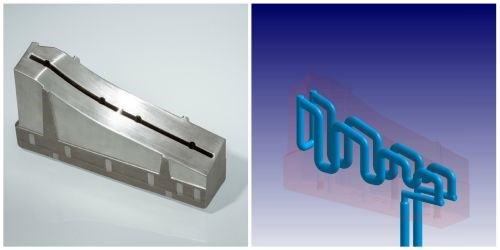

An example of a conformal-cooled insert produced at Linear Mold & Engineering.

Conformal cooling is a hot topic lately, and for good reason. By ensuring consistent temperature throughout the molding cycle, conformal cooling speeds production, improves part quality and reduces costs.

That’s great for the customer, but the potential return for the manufacturer diminishes with a longer production process and heavy workload. That’s been the case at Linear Mold & Engineering, a Livonia, Michigan manufacturer that has been using direct metal laser sintering (DMLS) technology from EOS to create conformal cooling channels for nearly a decade. Recently, demand increased to the point where the company was compelled to increase production efficiency for this lucrative market.

The problem wasn’t with the DMLS machines themselves—in fact, the company may have already made good on plans to add additional machines by now. Rather, the issue concerned surrounding processes: sawing inserts off the base plate, grinding off the base plate remnants, and finish-milling the inserts to size. Now, all of these operations are performed in a single setup on a Mitsubishi MV2400 wire EDM from MC Machinery Systems. Moreover, the operations can be performed on as many as five plates of conformal-cooled inserts at a time. Read this article to learn more.

Linear also recently appeared in Additive Manufacturing, a quarterly supplement produced jointly by MoldMaking Technology and the editors of sister publication Modern Machine Shop. That article details how the shop is leveraging customer service, education and training to grow its additive manufacturing business.

Related Content

-

Manifold Blocks for Flexible Cooling Circuits

Hasco’s Z920/ manifold blocks create a centralized inflow/outflow location that enables the use of shorter hoses in mold heating/cooling systems.

-

2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

-

Strategic Mold Cooling: Optimizing Molding Quality and Cycle Efficiency

Proper cooling is crucial in molding, yet often overlooked. Discover proper cooling methods to prevent defects and improve efficiency.

.jpg;maxWidth=300;quality=90)