Conformal Cooling

Part 2: New Tool Concepts for Machining Dies and Molds

The use of multifunction inserts is a significant geometrical development - making it possible to machine various operations with a single insert.

Read MoreUnderstanding the Relationship Between the Hot Runner and the Mold

Failing to understand and meet key mold design aspects - such as the importance of adequate structural back up between the cavity inserts, the mold plates and the hot runner system components - could compromise overall mold performance.

Read MoreFarm Out Your Mold Bases And Concentrate on the Little Things - Inserts, Cores and Cavities

Faced with the incessant challenge of shortening lead-times, more and more moldmakers are turning to outside sources for their mold bases and reaping the rewards of this decision: savings in time, money and headaches

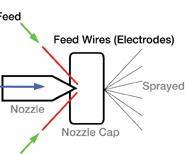

Read MoreRapid Tooling - Cast Resin and Sprayed Metal Tooling

Indirect tooling methods use the RP process to generate a pattern from which tooling inserts are made. This article describes two such indirect tooling processes - cast resin and sprayed metal tooling.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)