MMT Visits Linear Mold to See Additive Mfg in Action

Linear Mold & Engineering opened its doors to us to talk about how they’re using additive manufacturingI to grow conformal cooling channels inside mold inserts and to make production parts for the aerospace and medical industries.

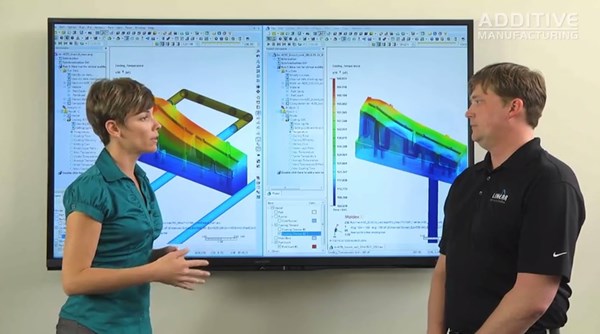

Linear Mold & Engineering is an innovative leader in tool building and part manufacturing using additive manufacturing (AM) technology. The company uses production 3D printing not only to "grow" metal parts that couldn't be made any other way, but also to create mold inserts with cooling lines that conform to the curves of the mold for improved heat transfer. Peter Zelinski and I, co-editors of Additive Manufacturing, visited Linear to film this video.

Related Content

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

-

2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

-

Pennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.