Conformal Cooling

Hybrid Milling Machine Improves Cycle Times and Part Yields

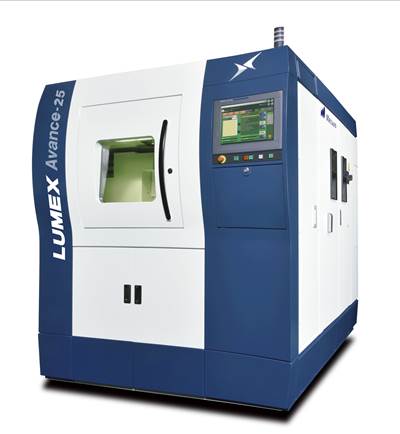

Custom Mold & Design Expands Services with purchase of a Matsuura Lumex Avance-25 metal laser sintering, hybrid milling machine.

Read MoreHybrid Milling Machine Fuses Metal Laser Sintering and High Speed

Matsuura Machinery USA, Inc. will exhibit the Lumex Avance-25 metal laser sintering hybrid milling machine at Amerimold.

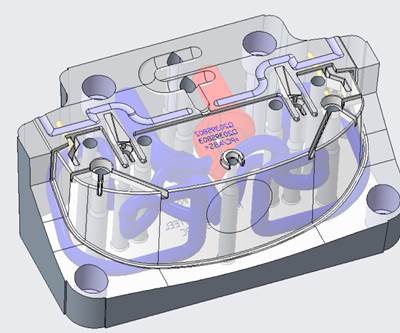

Read MoreConformal Cooling: Not Just Faster Parts but Better Parts

EVCO Plastics has been offering DMLS conformal-cooled inserts for years and like many shops today, they outsource this work to mold builders who have expertise in DMLS.

Read MoreAngle Pin Inserts Reduce Setup Times

PCS Company’s angle pin inserts reduce setup time by allowing the moldmaker to machine while doing other flat work.

Read MoreCapability to 3D Print H13 Delivers Robust Tooling

Direct metal laser sintering H13 material plays a big role in how this company has differentiated itself from the competition.

Read MoreTooling: New Safety Couplings for Mold Cooling Lines

Hasco’s new couplings have an automatic safety lock.

Read MoreHow to Improve Melt Distribution with Diffusion-Bonded Manifolds

Diffusion bonding for manifold manufacturing offers design freedom for optimizing hot runner melt distribution, reducing color change-over time, cavity-to-cavity weight variation, peak injection pressures, melt degradation, and resin flow stress.

Read MoreNew LP09 inserts Combine Higher Insert Corner Strength with Dual Cutting Edges

Seco Tools’ new, larger LP09 inserts combine higher insert corner strength with dual cutting edges to speed face milling.

Read MoreLatch Function on Stamp Prevents Movement on Arrow Inserts

Meusburger says that its stamps have a latch function that fixes the arrow insert into defined positions and guarantees that the arrow remains in a fixed position.

Read MoreDecrease Cycle Time with More Advanced Moldmaking Equipment

Today’s improved machine tools, tooling, workholding and CAD/CAM technology have made substantial gains over the last ten years. These advances allow shops to reduce the time it takes to machine cavities, cores, inserts and other components.

Read More

.jpg;maxWidth=300;quality=90)