Mold Components

Bar Locks Series Expand for Alignment of Large Molds

Progressive Components introduces an expansion of its Z-Series bar locks for alignment of large molds and multi-plate sequencing tools.

Read MoreRemote Validation Kit Expedites Qualifying Process

Progressive Components announces its remote validation kit, which enables tooling engineers to validate their tools remotely.

Read MorePrecision Machined Components Support Variety of Molding Technologies

Custom Mold & Design designs and builds high precision, fast cycling molds and precision machined components to support a variety of molding technologies including thermoplastic, elastomeric, silicone, metal injection molding, rubber and ceramics.

Read MoreDouble Ejection Systems Designed to Control Sequence of Plate Openings

CUMSA USA double ejections systems are designed to control the sequence of the double ejections or plate openings.

Read MoreBeing Connected to Community and Customers during COVID-19

Mold manufacturers and technology suppliers across North America have day jobs and night jobs when it comes to doing more to help both their customers and local communities during the coronavirus pandemic. Here is one mold component supplier’s story.

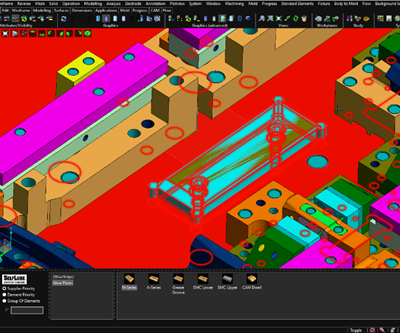

Read More3D Models in Components Library Eliminates Busy Work for Tool Designers

SelfLube announces 3D models for its entire product line of precision mold and die components are fully incorporated into the VISI CAD components library.

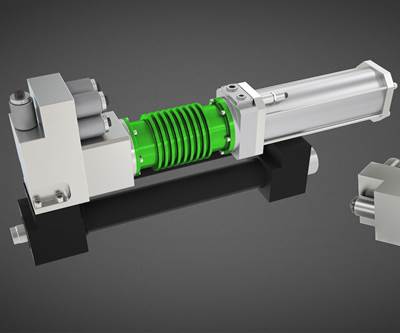

Read MoreDrive Technology Eliminates Fear of Contamination

J&H Distributor showcases the e-ahp drive, a force and position controlled linear axis capable of generating high forces.

Read MoreCOVID-19 Gives Mold Component Supplier Its Most Consequential Order Ever

The pandemic has presented challenges to every link in the mold manufacturing supply chain and those companies in a position to help have put their teams and processes to the test, including mold component suppliers.

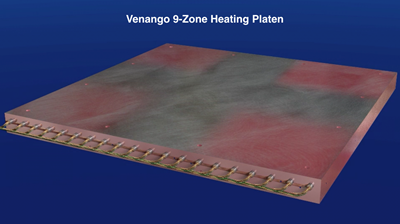

Read MoreHeating Platens Reduce Mold Surface Temperature Variation

Venango’s MultiZone heating platens with a control system reduces mold surface temperature variation by almost 400%

Read MoreCOVID-19 Is a Rallying Call to the Plastics Industry to Redesign, Refocus and Reshore

Mold manufacturers who have been critiqued for slow lead times, as compared to the overseas competition, are proving to themselves and customers during COVID-19 that North American mold manufacturers and suppliers can unite and do things at an extraordinary speed.

Read More