Being Connected to Community and Customers during COVID-19

Mold manufacturers and technology suppliers across North America have day jobs and night jobs when it comes to doing more to help both their customers and local communities during the coronavirus pandemic. Here is one mold component supplier’s story.

Staying connected

Stocking a local food pantry, building a “Strong” campaign to raise money to support local food emergency coffers, working through STAR Charities to set up a digital donation option, assisting a school lunch program, securing refrigeration capacity for airplane meals all are examples of how the team at Progressive Components—a supplier of mold components and mold monitoring systems—in Wauconda, Illinois, spends its “after hours” time during this coronavirus pandemic when not serving its customer base or supporting the moldmaking industry. And I believe one essential “component” to helping people is promoting what you are doing, so those in need can find you and get the help they need to keep the community and industry strong.

The warehouse workforce is filled with some top-notch quality individuals during this crisis.

When Progressive Components President Glenn Starkey started getting calls from customers saying, “I'm building ten molds for COVID-19 test kits, are you going to be open three days from now?” he saw firsthand just how much the industry was looking for assurance that their supply chain will really be there. It was then that the Progressive team took action.

“It’s not enough to just send an e-mail assurance to let people know the degree to which we are taking our responsibility seriously. It’s planning for a ‘no excuses’ determination to provide supply,” Starkey says. When I asked him how the company was doing that, he replied, “We just do, and we just will.” Actually, he says the key is to managing the supply chain and warehousing is to “communicate, communicate, communicate” —both internally and externally. Starkey even shared a video tour of Progressive’s HQ warehouse so that customers could see firsthand – or close to it—their level of preparedness.

First, the Progressive team has been monitoring its supply chain and lining up backups—even backups to backups. Then, same for its warehousing staff: they have a day shift and a night shift that never overlap. Employees are gowned up from head to toe. Warehouse hours have been expanded from 5AM to 9:30PM, and Customer Service staff now have expanded hours of operation to 7 days a week.

These ramped-up efforts are how Progressive is providing its “link in the supply chain”, like never before.

They also have two backup shifts established. To staff that, Starkey put a call out to local restaurant owners to hire people who were laid off to then be trained as warehouse technicians, as well as to former Future Business Leaders of America students who are now college students stuck at home. This strategy proved successful, creating additional shifts and a pipeline if they need more workers. “

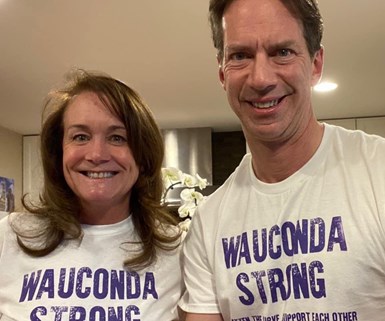

Glenn and Linda Starkey of Progressive Components work after hours to support their local community during the COVID-19 crisis.

Internally they took their monthly “These Progressive Times” employee newsletter, made it weekly and e-mailed it—as well as continuing to mail the monthly edition—to every employee’s home (no matter where they are in the world). The newsletter not only reports the current health of the company, but also shares leadership insights, personnel news, and even a little inspiration and humor. The company also holds virtual monthly headquarter and all-company meetings now via Skype.

On top of all that Progressive has increased its marketing and communication efforts regarding its benefits and product offerings too. Right now Starkey states that the team is laser-focused on informing customers as to what might be some unknown advantages for medical molds, such as greaseless components, stainless components, and components for molds for thin running resins such as LSR, nylon, and medical grade flex PVC.

Another example is remote monitoring. “Nobody knows how long many of us will be working remotely, or if after manufacturing begins resuming, if there’ll be further bumps before the curve is completely flat. So it is now more important than ever to ensure that a company’s next tooling release is remote monitoring-ready, because it may be the only way to know what molds are running versus not running, and if agreed maintenance intervals are occurring,” Starkey says.

People responsible for the productivity of a fleet of molds will need remote visibility as to what is occurring, and do so in an efficient manner. Rather than traveling to a mold sampling, picture a Remote Validation Kit that can be shipped from site to site to provide visibility to the status of the startup process. You can validate your molds remotely to speed up qualification of PPAP or the IQ/OQ/PQ approval process and expedite the mold into production … and get paid faster!

OEM Sales Manager Lorena Fisher describes the company’s Remote Validation Kit.

The Remote Validation Kit is a briefcase with a dedicated Microsoft Surface, a press module, and a gateway that a tooling engineer can ship to wherever a mold is in production and remotely check in, eliminating the need to travel.

Fisher explains the benefits of remote validation to the OEM, “Imagine you are an OEM that has tooling engineers who must drive or fly back and forth to suppliers’ sites to validate their tools. Now visualize a suitcase instead, with all the gear ready-to-go that can be shipped to a facility for remote mold qualification, providing added visibility to the status of the startup process and live data for authorized personnel.”

Consider a molder who has a mold that needs to get into production, but their customer can't travel to their site. The Remote Validation Kit will allow them to give visibility to that customer. They can even grant access to specific molds or specific fields within those molds. For example, real-time mold performance visibility, cycle count to the next PM, average temperature, etc. It also serves as a file cabinet for mold documentation, activity reports, and process sheets.

How about a molder who is having problems with a mold, but can't ship it to the mold builder because they are shut down? A Remote Validation Kit at the molders’ location will give the mold builder visibility into the tool so they can help in troubleshooting the problem.

“It is now more important than ever to ensure that a company’s next tooling release is remote monitoring-ready, because it may be the only way to know what how molds are running versus not, and if agreed maintenance intervals are occurring.”

“While remote validation is a new tool in the toolbox, it was built from our proven, global mold monitoring platform introduced ten years ago,” Fisher says. “It’s a plug-and-play solution for those suddenly rethinking their supply chain and how they will be connected to their vendors in not only a COVID-19 world, but beyond.”

“Will we get to the other side of this pandemic and be better for it? Well, I hope so,” Starkey says. “I do know this, that companies are definitely rethinking their supply chain’s preparedness, the critical performance of their tooling, and how they’ll be monitoring what's going on for the life of their programs. Nobody wanted this jolt, but it will rattle some old paradigms and for some, this all will drive large-scale improvements.”

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More