Mold Components

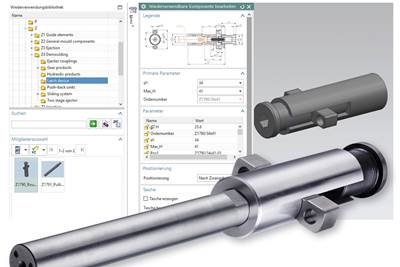

CAD Database Amplifies Mold Design Potential

The Hasco NX library, now featuring the integration of approximately 100 additional components, can be used directly in combination with Siemens’ NX CAD system.

Read MoreClean-Break Multi-Coupling System Centralizes Cooling Line Connection

The system removes cooling circuit and hose mix-up with a single process step, prevents cooling fluid leakage and includes 21 new products.

Read MoreHose System Better Secures Injection Mold Heating, Cooling Circuits

Expansion of Hasco’s Push-Lok system offers flexible, twist-free, kink-resistant hoses for quick repairs, secure connections and max service life.

Read MoreMold Component Supplier, Punch Industry USA, to Celebrate Fifth Anniversary in Illinois

Punch Industry supplies punches, button dies, core pins, ejectors, cores, cavities and inserts to U.S. mold/die makers, injection molders and metal stamping companies.

Read MoreHigh-Conductivity Core Pins

Regal BFP type high-conductivity core pins are made from C-18000 beryllium-free copper and promise resistance to wear, abrasion and thermal stress.

Read MoreLatch Locking Units for Precise Control of Parting Planes

Hasco’s new latch locking units feature double-sided action and DLC-coated functional surfaces.

Read MoreHot Runner, Mold Component Partnerships Lead to Innovative Mold Designs

Formula Plastics takes on tooling via sister company Formula Tooling using dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold designs.

Read MorePlate Retainer Offers Compact, Simple-to-Install Plate Sequencing Control

Introduction of Progressive’s Plate Retainer helps to eliminate stuck parts and mold damage as a result of plate drift when the mold machine vibrates.

Read MoreHere Are Your Top 10 Most-Read Features of 2021

A list of the most-viewed features in MoldMaking Technology from January to November 2021.

Read MoreMold Component Enables Fast Localization of Injection Molds

The Loc Check A5900, which has GSM tracking, is magnetic attachable to free surfaces of an injection mold and has a battery life up to 3,000 transmission cycles.

Read More