Case Study

Automation Alley: Recovering Together

Automation Alley’s mission is to grow the innovation cluster of Southeast Michigan. It creates business development opportunities and results for its members and stakeholders who share its values. By helping its members achieve success, Automation Alley aims to increase the quality of life in Michigan.

Read MoreNo-cost CAM Upgrade Gives Moldmaker Major Productivity Boosts

The latest version of Mastercam CAM software from CNC Software, Inc. contains several new features that will greatly improve productivity, especially roughing and fine finishing.

WatchEquipment Investment Allows Moldmaker to Zero in Medical/Packaging Niches

Tech Mold Inc. (Tempe, AZ)—a manufacturer of high-volume, multi-cavity molds for the medical disposable, packaging (caps and closures) and consumer markets—has invested just under $1,000,000 on new equipment over the past six months. These new capabilities have allowed the company to refocus its efforts in the medical and packaging markets.

Read MoreMoldmaker Hones in on Medical Projects

Matrix Tooling Inc. of Wood Dale, IL takes on projects others say can’t be done. It’s their niche. With about 70 percent of its business in the medical arena, their facility has a cleanroom for developing medical parts such as a smaller than four-inch long cartridge for a surgical stapler to suture veins.

Read MoreRalph Oswald of Chicago Mold is Named AMBA Mold Builder of the Year

The AMBA recently awarded Ralph Oswald, CEO of Chicago Mold Engineering Co. (CME), its prestigious Mold Builder of the Year award for 2012 at its annual convention in Grand Rapids, MI, this past May. I was honored to be present while outgoing AMBA president Mike Armbrust presented Oswald with this honor.

Read MoreReigniting Interest in Manufacturing With a Full-Ride Scholarship Program

New program aims to “AMP” up the nation’s youth into entering moldmaking with the proper education and training—for free!.

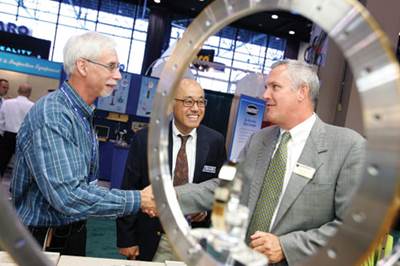

Read MoreThe Association For Manufacturing Technology: Promoting U.S.-Based Manufacturing

AMT believes cooperation and innovation are the keys.

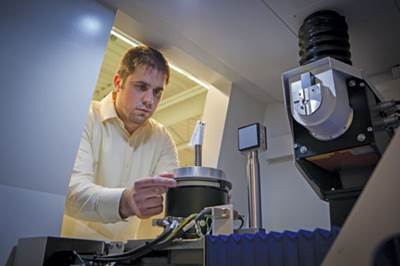

Read MoreCT scanning: A Differentiating Factor

NyproMold finds its growth in differentiation—including using CT scanning to look through parts with an accuracy of 5 to 7 microns, obtaining information that can speed the mold manufacturing process.

WatchLean Initiative Leads to Automated Metrology Solution

This cell has helped us reduce costs in the electrode manufacturing area—realizing a 26-month return on investment, which makes the justification for another system that much easier.

Read MoreHelping Shops Get from Quote to Cash Sooner

Manufacturers should be focusing less on how to reduce labor costs, and more on looking at how to take time out of the process.

Read More