Case Study

The Design Phactory: Churning Out Creative, Complex Mold Designs

“Mold builders make the best designers.”

Read MoreAttaining Outside Expertise Yields New Market Niche

“The skills and capabilities that Image brings augment our capabilities tremendously.”

Read MoreMaximizing the Manufacturing Process with an Injection Press

Minimize the overall costs of your customer’s project with the addition of a press.

Read MoreAngles Stop Negative Areas from Undercutting the Injection Process

The new vertical lifter design provides a range of advantages during mold construction: space savings, easier machining and simplicity of assembly.

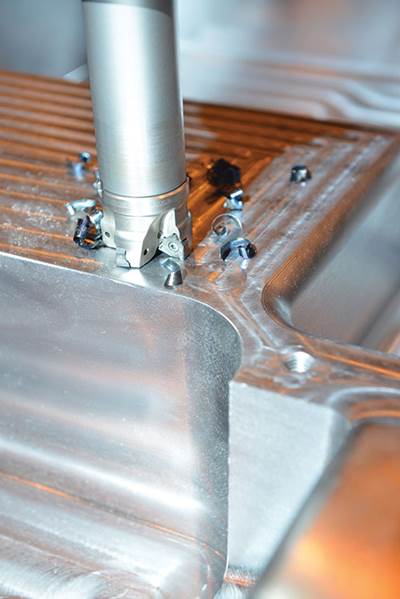

Read MoreSupercharging Rough Machining Performance with Advanced Tooling

What is amazing is that the shop is confident it could run the Seco cutter at 500 ipm if the machine was capable. It is this reason that Build-A-Mold is in the process of acquiring newer, faster equipment.

WatchFive Ways to Efficiently Tackle Shop Floor Management

Even the smallest mold shop can afford an integrated shop floor management system that allows for the management of every business transaction—from quote to cash—and is an invaluable tool for ensuring efficiency.

Read MoreMoving Moldmaking Forward with Dynamic Toolpaths

It's not a matter of how much equipment or manpower you have. What is more important is how well you use what you've got.

WatchEducation and Training Triumphs

The 2013 Leadtime Leaders detail their apprenticeship training and educational programs—and the rewards they reap.

WatchAdvantages of the Moldmaker/Molder Relationship Evolution

New, specialized roles prove to be a winning opportunity for the entire mold supply chain.

Read MoreMold Roughing

Tolerances and finishes on the Buss Precision's molds are tailored to the specific project, but most work is held to +/-.0002 tolerance on multi-cavity components, cavity, cores and parting lines.

Read More