Attaining Outside Expertise Yields New Market Niche

“The skills and capabilities that Image brings augment our capabilities tremendously.”

When Intertech Plastics Inc. (Denver, CO)—a manufacturer of custom injection molded plastic products—wanted to extend its markets beyond industrial plastics and consumer products into medical, the company decided to look into acquiring a company that already possessed this expertise. Enter Image Molding, a Denver-based injection molding and contract manufacturing service provider to the medical devices industry.

Intertech possesses a host of capabilities that include mold design and engineering support, in-mold decorating, high cavitation, high volume operations and molding. According Noel Ginsburg, CEO of Intertech, the company has wanted to enter the medical molding market for a number of years. “We believe the best approach is to acquire a successful molder who is already in the space,” he explains. “Image met all of our key criteria of strong customer relationships, consistent profitability, high quality performance, tool building capabilities and good management.”

Image Molding will join Intertech as the medical division of Intertech, and will be renamed Intertech Medical by January 2014. Ewan Grantham, President of Image Molding, will continue to lead Intertech Medical. “The depth of engineering and management support that Intertech brings will be a great enhancement here, as will the increased ERP technology and sales support,” Grantham comments.

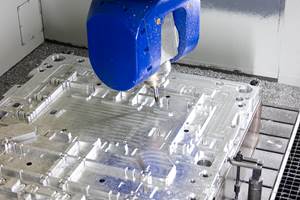

According to Keith Hamilton, Intertech’s Vice President of Sales, the tool design and mold manufacturing in place at Image has a history of helping customers bring complex, precision components into production. A full machine shop that includes multiple CNC and EDM machines allows the company to create molded geometry true to customers’ CAD files—maintaining a high level of precision through mold design, mold construction and processing of the molded components. “My challenge to Ewan at Image Molding was to have him figure out how to make these super critical parts with very tight process variability, resulting in a CPK of 1.33 or higher,” notes Perry Croll, Senior Director Anesthesia and Respiratory of medical device provider Teleflex (Research Triangle Park, NC). “We were asking him to hold tolerances—in some cases to ±0.0005 inches—in the molded parts. He has done that on a regular basis.”

In addition to mold fabrication, Tim Nakari, Director of Marketing for Intertech, notes that this partnership will allow Intertech to grow in other key areas—mostly cross-selling its wider range of capabilities. “It will enhance the value-add of current molding projects at Image,” he comments, “like providing pad printing and/or packaging and assembly solutions to existing molded programs.”

Nakari says this move will also introduce the company’s medical customers to the new capabilities available to them at the Intertech Plastics site. “We can now offer larger part size molding to medical equipment and device manufacturers,” he explains. “And as we grow, our new customers will be more strategically aligned with our new host of capabilities—and in ideal cases—be able to take advantage of our medical part expertise, high volume part expertise, precision mold design, and assembly and fulfillment services.”

Ginsburg concurs that Image is a great addition to the company. “The skills and capabilities that Image brings augment our capabilities tremendously,” he affirms. “Additionally, our ability to serve medical device manufacturers is further enhanced with the addition of even more high-end molding presses, controlled manufacturing environments, small parts expertise, and medical-specific protocol.”

For More Information

Intertech Plastics Inc. / (303) 371-4270

tnakari@intertechplastics.com

intertechplastics.com / intertechmedical.com

Related Content

True Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreRead Next

Moldmaker/Molder “Doubles Down” with Technology Investment

“At a time when many others are exiting the domestic tool making business because of its low margins and ever growing requirements for capital investments, we see it as a critical component to the ultimate success of our customers’ end product in the market.”

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More