Case Study

New Era, Same Winning Formula

This company succeeds by staying up-to-date on technology and being willing to do a bit extra in the name of customer service.

Read MoreCutter Sets New Standard for Heavy Hogging

A recent roughing application shattered this moldmaker’s expectations about the stability of a large face mill in long-reach contouring operations.

WatchFrom Camera Assembly to Full-Service Medical Manufacturing

Having already made a significant mark on the mold manufacturing sector, Canon Virginia is setting its sights even higher.

Read MoreLaser-Focused on Lean

This toolroom made significant strides in reducing waste and improving workflow with the addition of just one piece of equipment: a mobile, flexible laser welding system.

Read MoreMaking Wear Predictable

With thorough documentation and an investigative mindset, preventive maintenance becomes an uptime-boosting feedback loop of continuous improvement.

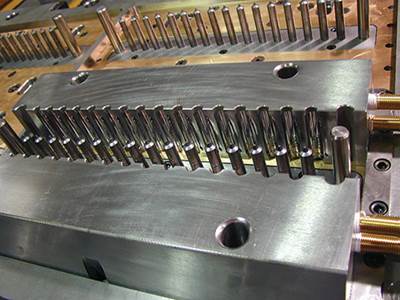

Read MoreA Dedicated Approach to Maintenance and Repair

Isolating these operations from the rest of the shop provides a competitive edge for this large plastic injection mold manufacturer.

Read MoreThe Knowledge-Driven Operation

From management to shop floor, putting control of processes and workflow in the right hands accounts for much of this growing mold manufacturer’s success.

Read MoreMasters of the Details

The right information, the right culture and a systems approach to every operation ensure nothing escapes the scrutiny of this team of mold manufacturing specialists.

Read MorePutting Design in the Driver’s Seat

Being an engineering-driven mold manufacturer has dramatically impacted this shop’s efforts to automate processes, develop its workforce and expand into new types of business.

Read MoreFrom Bottleneck to Project Accelerator

Laser scanning provides new inspection options and a faster alternative to CMM for this engineering and mold manufacturing company.

Read More