Build

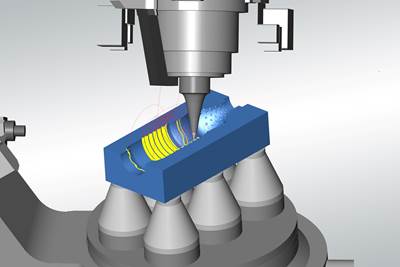

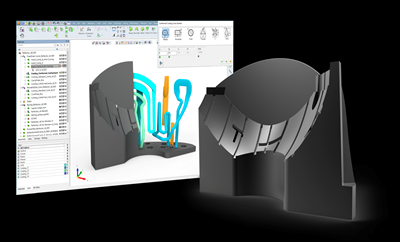

Customized CAM Strategies Improve Five-Axis Blow Mold Machining

The proper machining process and workflow can impact blow mold production, making your CAM software selection critical.

Read MoreCorrosion-Resistant, Highly Machinable Tool Steel

Opticut mold steels from Swiss Steel Group member Deutsche Edelstahlwerke apply a novel treatment to the material to eliminate the deterioration caused by the addition of sulfur.

Read MoreController Cart Transports Hot Runner Control Units Closer to the Mold

Avoiding the risk of collisions or damage, the Hasco Co-Cart safely positions external control units nearer the injection molding machine, with additional storage space for common spare parts.

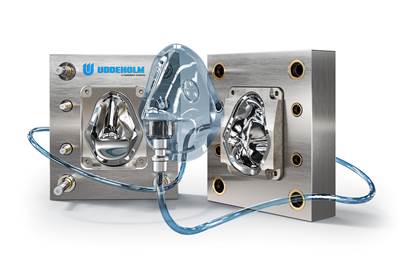

Read MoreCorrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s premium Tyrax ESR can reduce polishing time by 40-50% and is suitable for long run production molds and high-performance plastics.

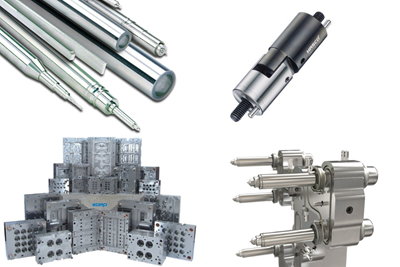

Read MoreEnhance Your Moldmaking Capabilities With These Hot Runner and Mold Component Products

MMT highlights new and improved innovations, including data collection devices, pins, bases, controllers, bushings, nozzles, positioning systems and much more.

Read MorePre-Hardened Mold Steel Material Increases Through-Hardened Ability

Finkl Steel’s patented pre-hardened mold steel grade MD Xtra material achieves high impact strength, enhanced thermal conductivity and is an exceptional solution for deep impression applications.

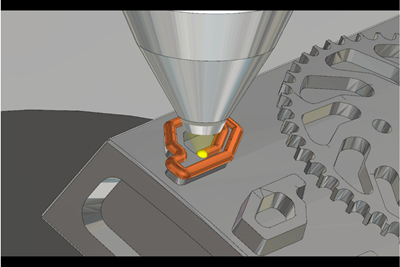

Read MoreRepair, Repurpose Tooling in One Process with Hybrid/Additive Manufacturing

Open Mind Technologies offers an Additive Manufacturing capability option to hyperMILL to support 3D printing/additive processes, such as DED, WAAM and laser powder.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreEnd-to-End Conformal Cooling Design, Production for Faster Cycle Times, Boosted Part Quality

Cimatron works with moldmakers to design and optimize molds with conformal cooling, prepare it for an accurate print and ensure complete post-processing.

Read MoreMold in a Day Technology Slashes Tool Production, Eliminates Supply Chain Headache

Next Chapter Manufacturing says its Mold in a Day additive manufacturing technology slashes the production of tooling down to hours while maintaining the same quality and tolerance standards of conventional molds.

Read More