Mechanical System for Slides Enables a Decrease in Mold Size

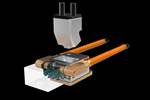

CUMSA USA highlights its LS, the new long stroke for slides. It’s a mechanical system designed to expand slide travel up to 100 mm, therefore significantly decrease the mold size.

Source | CUMSA USA

CUMSA USA highlights its LS, the new long stroke for slides. It’s a mechanical system designed to expand slide travel up to 100 mm, therefore significantly decrease the mold size.

Molds with long strokes present several challenges due to the complexity and precision required in their design and manufacturing. It’s well known that the longer the stroke is, the larger the mold will be. Moving big molds will ultimately be more complicated, as they require more time, effort and larger transportation machines. The LS system was created with mold reduction in mind, even in the event of longer strokes for larger molded parts.

The LS has a compact design making it easier to fit into any application. The product can be attached to any slide to produce a better performing mold. The only machining required to install the system to any slide is a simple grove on the side of the slide to guide the LS. It can also be applied to any conventional movement, even on existing molds.

This product features the patented CUMSA Double Rack system and is a 100% mechanical solution which comes with a slide retainer, designed to replace any angle pin by a perpendicular rack instead. Thanks to the 45° of the teeth, CUMSA obtains a 1:1 relationship, so the length of the guide is equal to the stroke. For 100 mm of travel, a 100 mm rod is needed with all of the movement being perpendicular.

The LS is a 100% mechanical solution designed to expand slide travel up to 100 mm. without the use of angle pins or hydraulics. Can be attached to slides with angles inclinations from -25º to +25º. The product comes initially out in two different rod diameters: Ø20 and Ø30, with three optional strokes: 50, 75 and 100 mm each, to ensure the proper movement of the slides. Mirror parts are also available for more mounting options. The LS can be attached to single sided slides or in duplicate, for large slides.

The system will help to reduce the size of the mold and still provide great robustness. With an estimated overall cost reduction up to 30% and a more effective production when the product is installed with the slides.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.