Build

VIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

WatchFive-Flute End Mill Delivers Dynamic Performance

The new M.A. Ford TuffCut XV Series XV5CB end mill was designed with a thick core for exceptional metal removal and aggressive stepover capabilities.

Read MoreOnline Mold Base Configurator for Simplified Mold Base Ordering

PCS Company’s online Mold Base Configurator enables a three-step process to configure and order high-quality mold bases.

WatchInjection Mold Guiding System Precisely Positions Mold Halves, Mold Components

Agathon Machine Tools highlights its tried and true all-in-one Guide System Plus at IMTS 2022 to meet productivity demands and reduced production cost.

Read MoreTechnology Roundup: Additive Manufacturing, Mold Materials

Upgrade your manufacturing process or tool steel choices with new/improved additive manufacturing and mold material innovations from AddUp Inc., Mantle, Next Chapter Manufacturing, Edro and more.

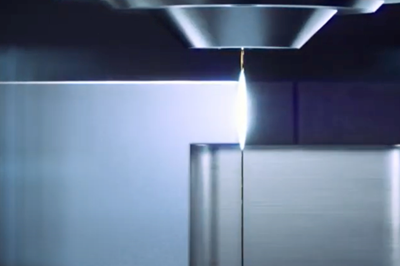

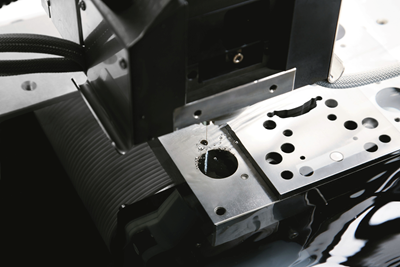

WatchWire EDM Function Eliminates Wire Breakage, Reduces Consumption

GF Machining Solutions’ new iWire function automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process.

Read MoreGundrilling Flexibility for Medical Applications

At IMTS 2022 UNISIG is spotlighting some of its extreme depth-to-diameter hole drilling technologies and their advantages in medical production.

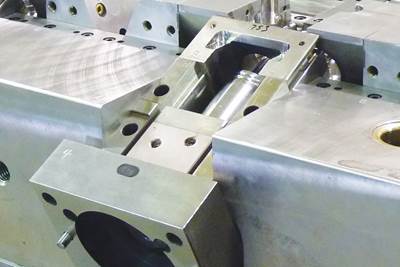

Read MoreHow to Solve Core Pull Flash and Part Issues

Many mold problems can be solved by simply providing enough preload force on the core to prevent movement.

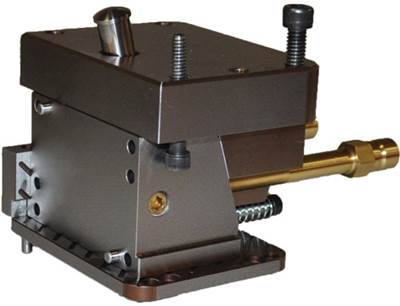

Read MoreCalculating the Benefits of Standard Slides

Design flexibility, time savings, engineering support and design assistance are great benefits to moldmakers from standard components.

Read MoreWire EDM Machine Enhanced With High Precision, Intelligent Interface, Service Support

GF Machining Solutions spotlights the new CUT X 500 and CUT P 350 Pro wire-cutting EDM machines with heightened accuracy, precision and productivity at IMTS beside tooling, automation and software partner, System 3R.

Read More